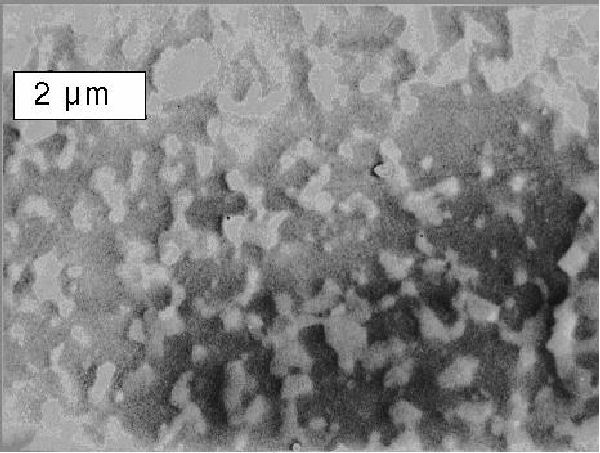

Submicrometer Aluminium oxide / Titan(C,O) cutting ceramic (average grain size 0.5-0.7 µm).

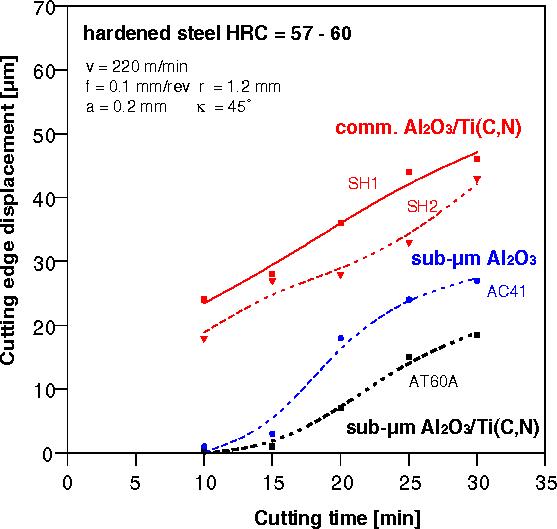

Precision turning of hardened steel (hardness HRC=60) with Al2O3/Ti(C,O): minimum cutting edge displacement and highest precision compared with sub-µm Al2O3 and with advanced commercial composite tools.

Advances in the machining of hardened steel

Specific properties of Ti(C,O) powders on processing enable for the first time the manufacture of high strength and extremely hard tool composites with grain size < 0.7 µm for improved hard machining at cutting velocities in the range of 200 - 250 m/min

Advantages

- High hardness (HV = 2100-2350) and thermal stability of Al2O3/Ti(C,O) composites with sub-µm microstructure minimize up to about 300 m/min cutting forces, tool wear, cutting edge displacement and the roughness of the machined part (e.g. precision machining of hardened steel [hardness HRC=60])

- Reduced tool wear compared with advanced commercial grades and submicrometer sintered corundum tools at velocities near the upper limit of the use of commercial Al2O3(Ti(C,N) composites

- Advantages in fine machining with highest precision of smaller hardened parts (velocities of about 200-250 m/min)

- Favorable manufacturing opportunities by possible use of coarser Ti(C,O)-raw powders

Products and services offered

- Development of technologies to manufacture submicrometer Al2O3/Ti(C,O) cutting ceramics, upscaling investigations

- Development of optimized materials for specific applications

- Application related cutting tests