Lithium-ion batteries

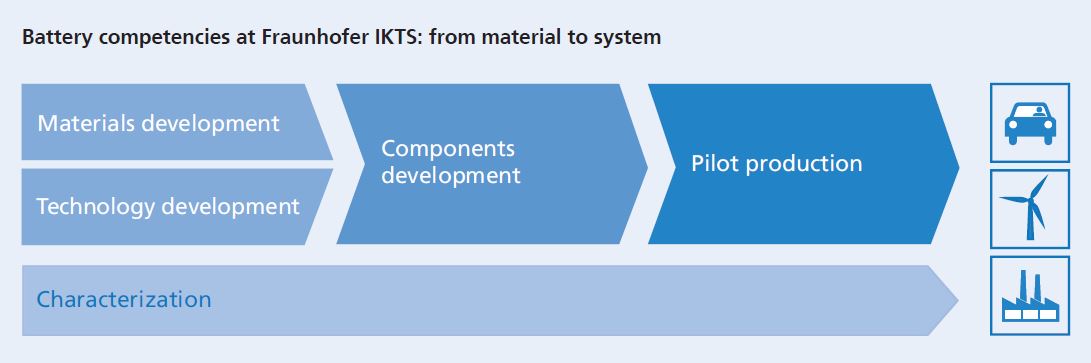

Ceramic materials and technologies are essential components of today’s lithium-ion batteries and will continue to play a key role in the future. At Fraunhofer IKTS, development work is aimed at the pilot scale to ensure a fast transfer of the results from fundamental laboratory research to industrial process development.

Fraunhofer IKTS applies its ceramics expertise towards synthesizing and preparing active materials and separator components, and processing them to form battery electrodes. A variety of methods is available for characterization of the electrode structure, electrochemical behavior, and aging during battery operation. As a result, a thorough understanding of the relationship between production conditions and battery reliability has been gained.

Decades of know-how in development of ceramic materials and technologies as well as in materials analysis and electrochemical characterization ensure that new cost-effective strategies can be established. This involves materials, process, and systems development as well as supply of groundbreaking cell concepts for mobile and stationary applications.

In addition to the mentioned materials and technology competencies, Fraunhofer IKTS has extensive know-how in the field of materials recovery and circular economy. With the development of efficient recycling concepts for lithium-ion batteries, it contributes to ensuring that energy storage systems are not only technically and economically convincing, but also in terms of environmentally friendly and sustainable production.

Cooperation models

Innovation and development are the cornerstones of a promising corporate future. In order to create a competitive edge, Fraunhofer offers tailored options for cooperation, so that small and medium-sized companies can work together in the best possible way. This also allows to utilize development skills at short notice and as needed.