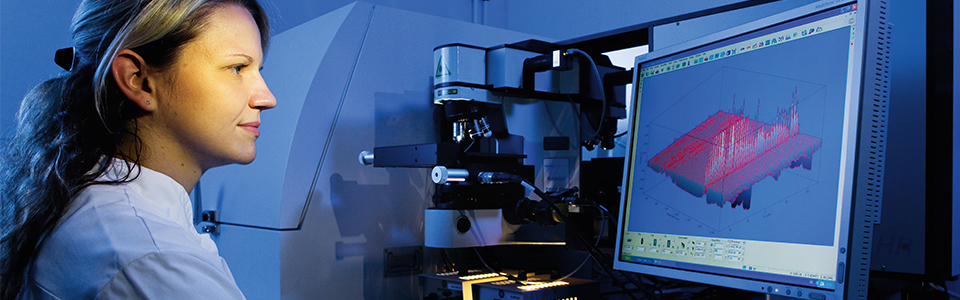

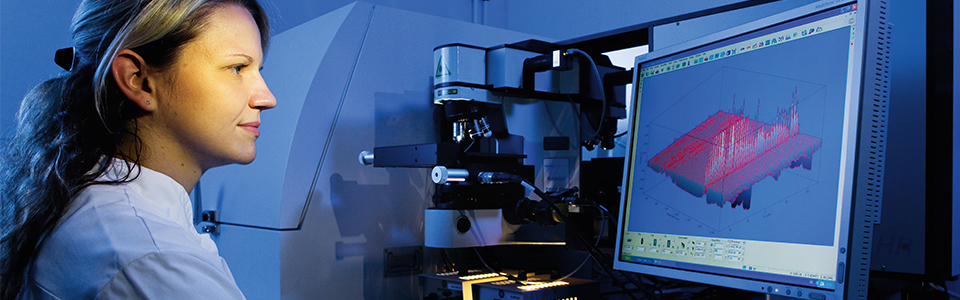

Characterization I Analysis I Measurement I Testing

One stop shop for all analysis requirements

Fraunhofer IKTS serves as an initial contact for all problems related to analysis, evaluation, and optimization of materials and components as well as the associated manufacturing processes. Focus is primarily on ceramic and powder metallurgy (PM) materials and components as well as materials and components used in microelectronics.

Fraunhofer IKTS possesses state-of-the-art equipment and an extensive range of modern analysis methods for:

- Applied research and development

- Characterization of feedstocks and materials

- Monitoring and optimization of ceramic and PM production processes

- Quality assurance of components and parts

- Failure analysis and evaluation of behavior of materials and components in specific applications

Both standard and in-house, in part unique, analysis capabilities are available. With extensive materials, process, and analysis expertise, Fraunhofer IKTS provides support and advice in development of new materials and products, determination of characteristics, clarification of complex failure mechanisms, and compliance with regulatory and qualitative standards. Accreditation has been granted for specific measurement methods for determining powder and suspension characteristics as well as thermophysical and electrical/dielectric properties and for selected NDT methods.

This gives Fraunhofer IKTS the capacity to handle diverse tasks related to quality assurance and certification of products and processes all the way to prototype testing for customers. Fraunhofer IKTS guarantees the confidentiality and security of all data and information handled within the scope of project work.

Cooperation models

Innovation and development are the cornerstones of a promising corporate future. In order to create a competitive edge, Fraunhofer offers tailored options for cooperation, so that small and medium-sized companies can work together in the best possible way. This also allows to utilize development skills at short notice and as needed.