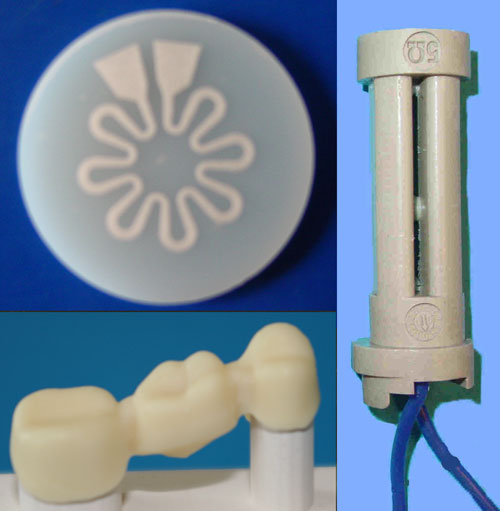

Ceramic and polymer-ceramic Components: Sensor element (left top), Highl power starting resistor (right), ZrO2 bridge frameworks(left below).

Servo-motorized CNC press.

Profile

- Oxide ceramic materials with high density, purity, strength and functional dopants for customized applications using superfine starting powders

- Ceramic materials with homogeneous,poor in defects and superfine structure design

- Optoceramic materials for Photonic Technologies

- Bioceramic and glass-ceramics for dental and surgical implants

- Ceramic-like composites (polymer ceramics) based on pre-ceramic silicone polymers with an advantageous combination of ceramic-like and plastics-like properties

- Development of industry-oriented manufacturing technologies with the inclusion of modern production technologies to assure custom-designed structur-property-relation

Services offered

- Development of single and multi-phase oxid ceramic components for special applications(mean system is Al2O3-ZrO2-MgO-Y2O3-SiO2)

- Polymer ceramics with fiber reinforcement and functional filling (electrical , thermal , and dielectric conductivity)

- Prototype- and small series manufacturing according customer specification

- Manufacturing technologies to avoid flaws for advanced properties

- Development of ready- to- press granules

- Uniaxial dry pressing for samples

- Slip casting of ceramic components with complex geometry

- CAD/CAM-process chain for manufacturing for instance dental restorations

- Manufacture of material composites combining ceramics and metals or polymer ceramics, ceramics, and metals

- Plastic forming of plastics and thermo-set materials (injection moulding, extrusion, warm pressing)

Technical equipment

- Ultra fine milling from sub-µm- to nm-range

- Spray dryers in laboratory

- Uniaxial dry pressing (mechanical and hydraulic)

- Shear roll for manufacture of granulates

- Scanner/4-axis-CNC-milling machines

- High pressure injection moulding equipment

- Thermal processes (reductive and oxidic)

- Final machining ( precision grinding and lapping)

- Measuring mixers and rheometers for determination of flow properties of high viscous and reactive materials