Hydrogen utilization

Hydrogen for climate protection

The use of hydrogen is aimed at reducing greenhouse gas emissions, like CO2 and other climate-damaging gases, such as methane. Efforts focus primarily on applications which to date are using fossil energy carriers to provide electricity (e.g. coal and natural gas in power plants) or driving power (e.g. diesel or gasoline in vehicles).

However, a major share of CO2 emissions in Germany – roughly 21 % – stems from complex industrial processes. The use of green hydrogen enables climate neutrality for processes in industry which today still result in high greenhouse gas emissions. This leads to two possible strategies: the use of CO2 while employing hydrogen to produce valuable chemical products (carbon capture and utilization, CCU), and the complete avoidance of emissions by substituting carbon in the process chain (carbon direct avoidance, CDA).

Hydrogen as process gas

CO2-free production processes

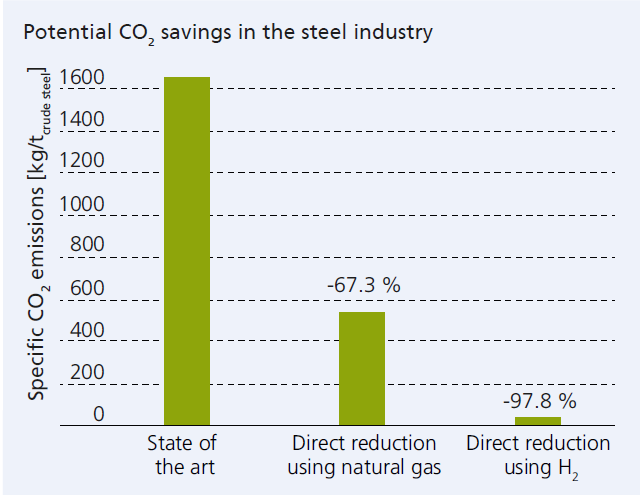

Ammonia and steel production are two particularly relevant areas with potential for reducing emissions where hydrogen-based concepts for direct CO2 avoidance can be used very effectively. In steel production, coke is used in the established blast furnace process as reducing agent to convert iron ore into pig iron. To avoid the CO2 typically released in this process, it is necessary to convert this reduction process from a coal-based one to a hydrogen- or syngas-based one. So-called direct reduction processes are already technically proven for operation with natural gas, but they can also be operated with hydrogen. The use of large-scale electrolyzers allows to significantly reduce emissions in steelmaking.

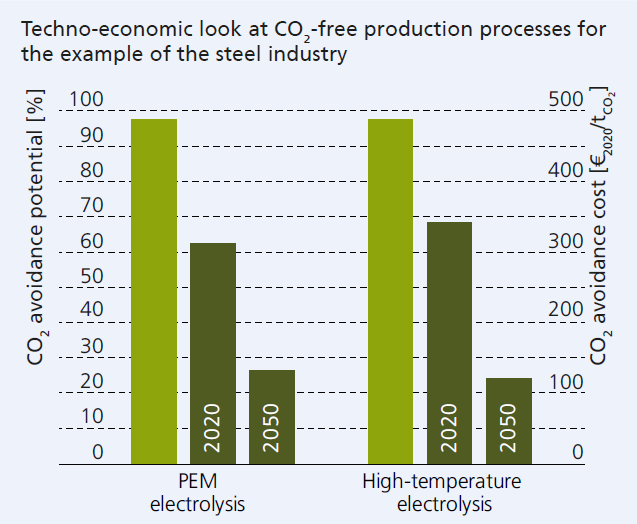

In particular, high-temperature electrolysis is an exceedingly promising technological approach in this regard, since available waste heat can be used to increase efficiency. Additionally, syngas can be produced within the electrolyzer. Fraunhofer IKTS develops process concepts based on its own solid oxide cells and stacks. These have a modular design to flexibly integrate renewable energy. This makes it possible to provide balancing power from the steel mill to the grid and support the renewable energy system.

Ammonia, a basic material for fertilizers, has become a key component for feeding the world population. In addition to nitrogen, the synthesis of ammonia also requires hydrogen. Hydrogen is currently produced from natural gas via steam reforming, with large amounts of CO2 being released. Electrolysis represents an alternative approach. Since the established reforming process also yields the required nitrogen, this nitrogen needs to be made available other means, e.g. via air separation. This requires new and efficient processes, which especially need to be economically viable. Technoeconomic analyses conducted at Fraunhofer IKTS have shown that high-temperature electrolysis can also be used advantageously in such cases.

Low-CO2 steelmaking or ammonia synthesis requires reconfiguring a large part of the traditional process chain. This is associated with high investment costs, but it in turn makes considerable emission reduction possible. As high-temperature electrolysis offers significant advantages with regard to operating cost, thanks to its high electric efficiency, efforts at Fraunhofer IKTS currently aim on a scale-up of the technology. In addition to the mentioned applications, the green hydrogen produced via electrolysis can also be used in the short term in existing refineries, replacing grey hydrogen from the steam reforming of natural gas.

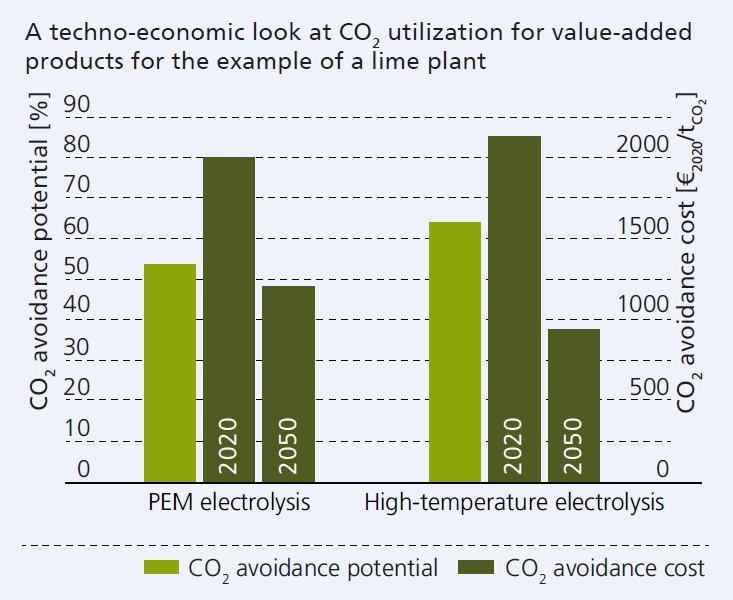

CO2 use for value-added products

In addition to using hydrogen to avoid CO2 emissions, it is also possible to utilize unavoidable CO2 emissions as carbon source. This makes it possible to produce value-added products, such as fuels for air and heavy vehicle traffic or higher alcohols and waxes as starting materials for the cosmetics and chemical industries. Based on higher net profits, such value-added products are able to additionally increase the economic viability of new production routes, e.g. in the lime and cement industries. However, it is still necessary for large-scale applications to provide sufficient incentives for building and operating plants based on electrolysis.

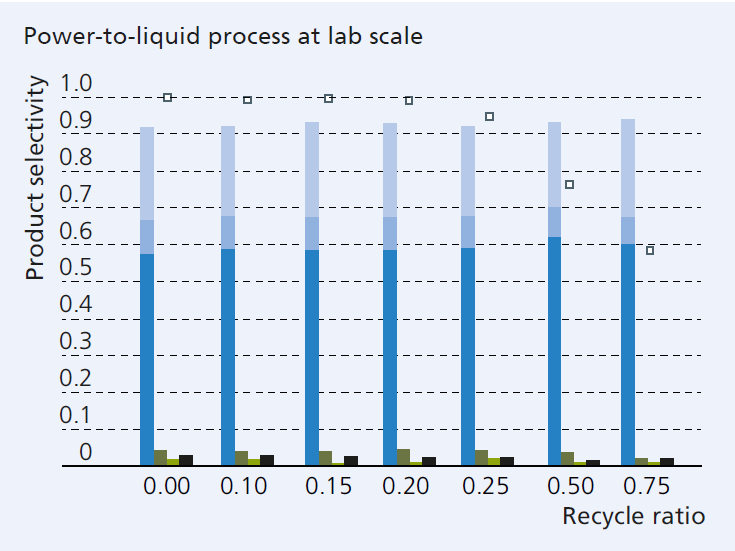

Fischer-Tropsch synthesis as a technology is particularly well-suited for the production of value-added chemicals from CO2 and hydrogen. This process yields a large number of different carbon-based products. In order to retain maximum levels of energetic efficiency and carbon utilization, the process must be coupled as closely as possible with electrolysis or co-electrolysis. Furthermore, the co-electrolysis process directly provides syngas. This will help to make the production of value-added chemical products as efficient as possible. In addition to theoretical analyses of the process chain, Fraunhofer IKTS also focuses on extensive development efforts on ceramic catalyst supports and reactors for Fischer-Tropsch synthesis. A plant specifically developed and operated at IKTS was already able to demonstrate the complete process chain of the production of high-value products from CO2 and H2O. The know-how thus gained is currently put to the test in pilot and demonstration plants at industrial sites.

Hydrogen as energy carrier

Electricity and heat

Next to using green hydrogen to produce important base and value-added products, its use as chemical storage is another option. This makes hydrogen a key element of renewable energy systems, opening up various pathways for its direct utilization.

One option is hydrogen storage in suitable caverns and the reconversion of hydrogen into electricity as needed, using gas turbines or highly efficient high-temperature fuel cells. This provides balancing power for the power grid, helping to stabilize it even when the share of renewable energy sources is high. For this purpose, Fraunhofer IKTS has already designed and successfully applied system concepts going beyond fuel cells and stacks, for instance for the energy supply of house-holds and for the conversion of biogas to electricity.

Also, hydrogen can in the future be used as a renewable alternative to fossil fuels in industrial firing plants in steel, lime and cement production in order to provide the high temperatures required by these industries. This is therefore another area where a reduction of CO2 emissions can be achieved.

Mobility

The mobility sector poses a particular challenge with urgent need for change. Over recent decades numerous initiatives failed to achieve reductions in CO2 emissions in this field. Next to purely electric drives, trains and trucks working with hydrogen represent a potential solution in the mobility sector, in conjunction with expanding public transportation.

To make hydrogen technologies for mobility acceptable for the broader public, the available infrastructure needs to be economically efficient and, most of all, reliable. The main component for the storage of liquid hydrogen is the pressure tank, which is manufactured increasingly as a wound component made from carbon fiber reinforced plastics (CFRP).

For the permanent monitoring of hydrogen pressure tanks, Fraunhofer IKTS offers a monitoring system based on guided ultrasonic waves. If structural changes or defects in the material occur, the measured signals will deviate significantly from the original, defect-free state. By comparing the signals with entries in a defect database, we are able to localize and classify structural changes or defects. In the future it will additionally be possible to make statements on the pressure tank’s remaining service life. The monitoring system can also be used to monitor hydrogen tanks in industrial settings.

In addition to hydrogen- and battery-powered vehicles, synthetic hydrogen-based fuels are also set to gain in popularity. Next to heavy vehicle traffic, this is particularly relevant for the air traffic sector. In these areas, the processes for using CO2 to produce synthetic jet fuel, developed by Fraunhofer IKTS, are particularly interesting.