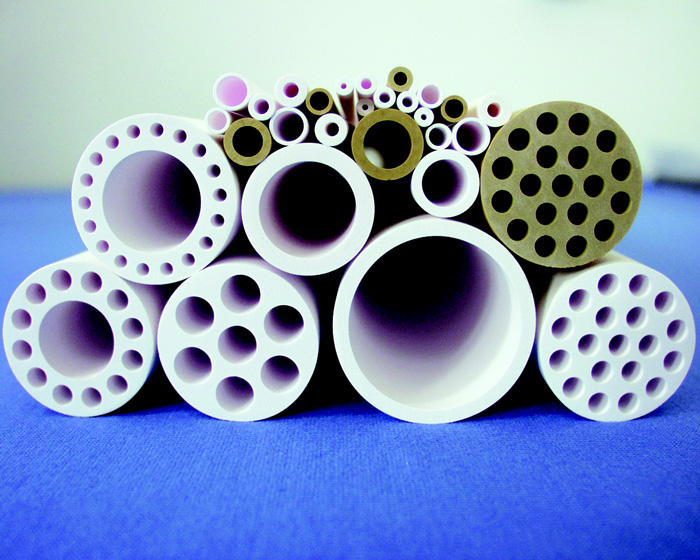

Porous, ceramic carrier pipes of various geometries.

Stainless steel module with ceramic membranes in 19-channel geometry.

Clean room for membrane coating.

The “Membrane Prototypes” group focuses on how to scale up membrane production and the synthesis of sample membranes for industrial pilot plants. In this context, up-scaling includes the geometrical dimension of the membranes, as well as production methods. Currently, oxide ceramic membranes for liquid filtration on single- and multi-channel geometries, as well as zeolite NaA membranes for pervaporation and vapor permeation on multi-channel pipes can be produced.

The membranes can be synthesized on carrier tubes with a length of up to 1.2 m and in sufficient numbers for equipping industrial pilot plants. Furthermore, flat membrane geometries are also available.

Services offered

- Manufacture of ceramic membrane prototypes for liquid filtration, pervaporative separation and vapor permeation on ceramic carrier pipes up to 1.2 m long

- Equipment of industrial pilot plants with membrane prototypes

- Synthesis of ceramic membrane prototypes in industrial size with customized properties

- Development of processes for the industrial manufacture of ceramic membranes

- Development of quality assurance procedures for industrial membrane production processes