Indirect natural gas drying with hydrophilic zeolith membranes

Current research

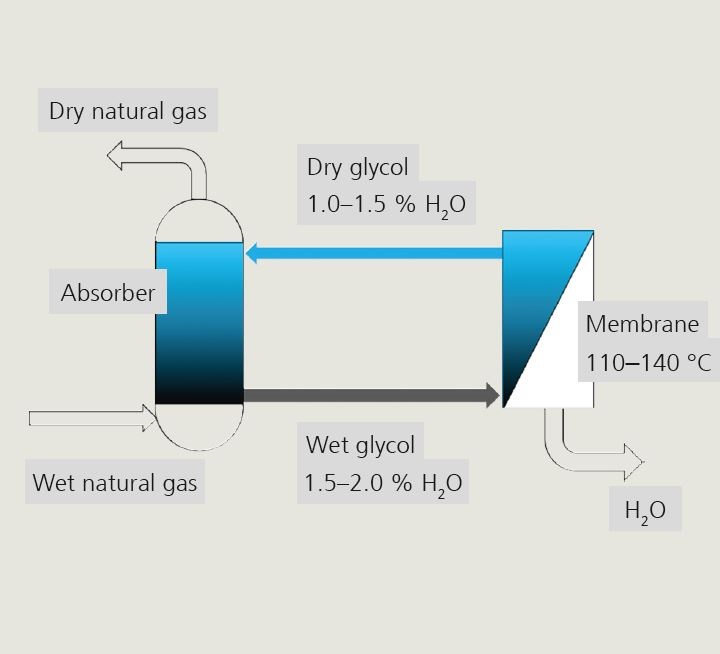

Natural gas has to be buffered in underground storage facilities to accommodate seasonal fluctuations in demand. During storage, natural gas absorbs humidity. When gas is extracted from the storage site and pumped into pipelines to consumers, it has to be dried again in order to avoid condensation. Normally, this drying process takes place by an absorption process using triethylene glycol (TEG). The TEG operates in a water vapor loading range of 0.5 to 2 wt %. After water absorption the TEG has to be regenerated. This is conventionally done by distillation at temperatures of 190 to 205 °C. The high regeneration temperatures cause thermal degradation of the TEG. Hence, the TEG has to be changed regularly.

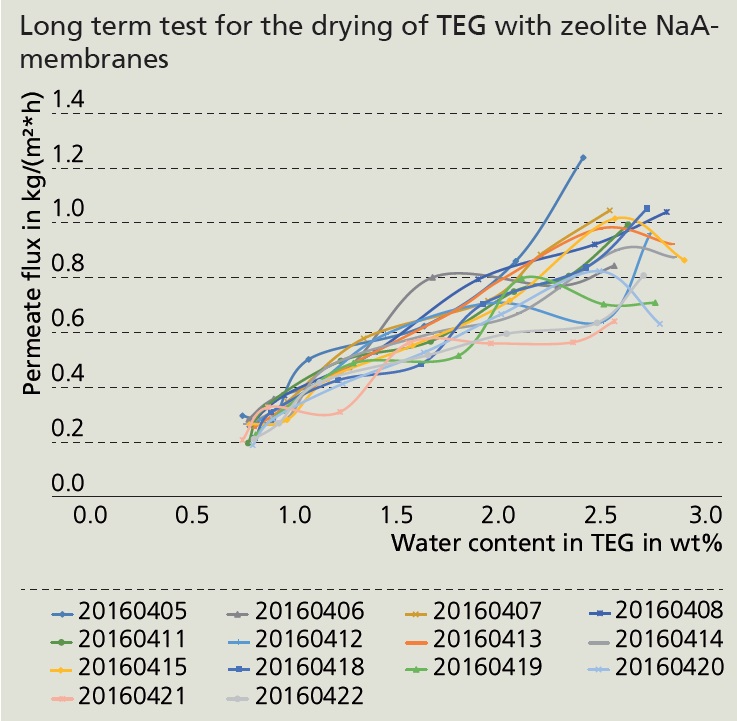

These high regeneration temperatures can be avoided through use of a hydrophilic zeolite membrane that was developed for drying of organic solvents. The membranes show convincing separation properties in ethanol dewatering by pervaporation or vapor permeation. The permeate, which is drawn off of the membrane in vapor form with a low ethanol content, is returned to the distillation column. In the drying of the TEG, the permeate must be free of TEG because otherwise it would remain in the ceramic membrane substrate and accumulate there due to its low vapor pressure. Transport of water vapor would be greatly hindered by the clogged pores. Within the scope of the project, iterative optimization of the individual steps in the membrane synthesis process yielded a considerable improvement in membrane quality. Selected membranes show largely TEG-free permeates in long-term tests. Large-scale testing is now being carried out in a pilot plant with a membrane area of 20 m² (225 membranes) for drying of TEG from the underground storage site in Stassfurt.

We gratefully acknowledge the BMWi for the financial support of the “MEMTEG“ project (03ET1101c) and the partners innogy SE, VNG Gasspeicher GmbH as well as DBI-GUT GmbH for the successful cooperation.

Supported by