Both, the dimensional accuracy and surface quality are of great importance for the realization of high standard advanced ceramic components. In many cases this requires a final machining process, i.e. a finishing process after sintering, which is very cost-intensive. The processing of component systems with ceramic components is also increasingly focused.

Products and services offered

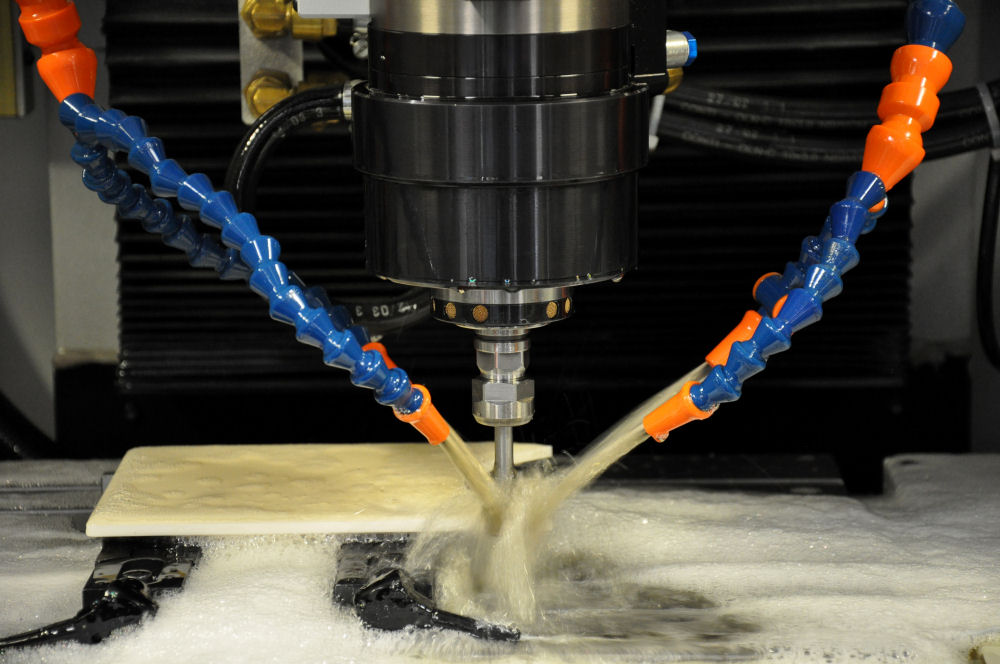

- Machining of test specimens and samples for materials characterization with high tolerance and surface requirements

- Machining of prototypes for component development

- Machining of component systems with ceramic components

- Micro machining

- Measurement of position, dimensional and shape tolerance as well as surface quality

- Selection and adaptation of machines, tools, clamps and technological parameters for machining requirements

- Optimization of conventional processing technologies under consideration of removal rate, reproducibility and damage of material and surfaces

- Development of superfinishing methods

- Selection and adaptation of machines, tools, clamps and technological parameters for in the context of feasibility studies, up-scaling and production planning