Mechanical and Automotive Engineering

Profile

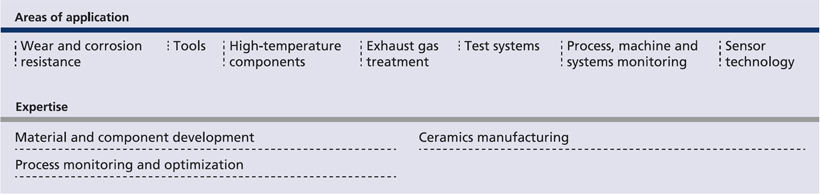

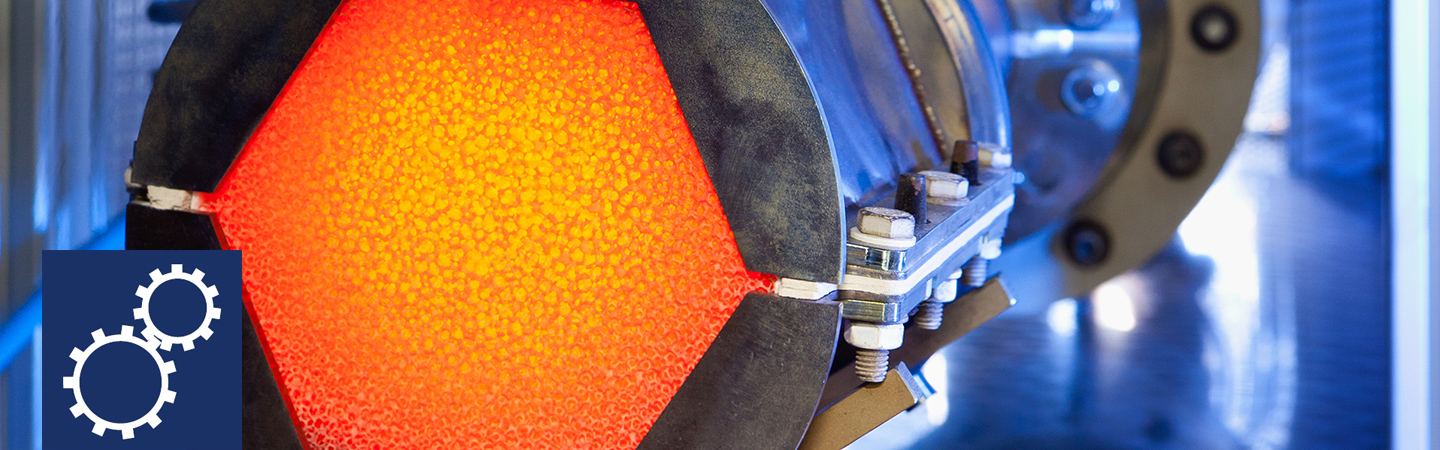

The “Mechanical and Automotive Engineering“ business division at Fraunhofer IKTS traditionally offers wear parts and tools as well as components for extreme conditions made from high-performance ceramics, hardmetals, and cermets to be used in machine building, plant engineering and automotive industries. Optical, elastodynamic and magnetic test systems for the monitoring of critical components and production facilities constitute a new area of focus.

The rising costs of energy and raw materials represent in combination with intensified competition in the global markets and increasing demand for sustainability some of the actual challenges for mechanical and systems engineering. Tightened exhaust and fuel efficiency standards have to be met in automotive engineering. By using high-performance ceramic components existing and new systems can be substantially improved.

Fraunhofer IKTS supports its customers with the application-oriented selection and development of materials, while utilizing both established material systems and new combinations. The IKTS team has decades’ worth of experience in designing components that leverage the best qualities of ceramics and hardmetals. It is also a veritable font of knowledge regarding the most economically feasible production processes and their successful integration into the user environment. Thus, new application concepts are both swiftly and affordably implemented in prototype and small-scale series production. When selecting a production process, the team can choose from a broad range of ceramic manufacturing processes that is truly outstanding in terms of its sheer breadth and depth. The existing equipment and installations facilitate the institute‘s holistic approach: from upscaling processes on the pilot-plant scale to transferring these processes into industrial production. Test and monitoring systems track the operational status of components and systems. They detect and localize defects early on. A broad and in some aspects unique portfolio of methods for the non-destructive detection of critical material parameters, such as fiber structures and microstructures, mechanical stress, porosity, crack formation and delaminations is available to select the optimum evaluation method. Signals are detected, processed through high-performance hardware components, then visualized and interpreted by the in-house developed software.