Mobile ultrasonic rail testing system

Current research

The requirements for rail-bound route networks are constantly increasing. With the demand for the highest possible level of operational safety, both the scope and the frequency of inspections increase while the time windows available for this are becoming smaller and smaller.

With “Smart Maintenance”, a condition-oriented action planning and rail processing, the maintenance process can be simplified and accelerated in a targeted manner.

Success factor digital condition recording

Condition data of rails and switches, such as operational irregularities in the rail interior, corrosion at the rail foot or defects in the vol-ume, are often collected with different systems of non-destructive testing. With the SoniQ Rail Explorer (SRE), developed on behalf of Vossloh Rail Services GmbH at Fraunhofer IKTS, an ultrasonic rail inspection device is now available, which records different data with only one measuring system in only one test run. The combination of various test data, video or ultrasonic signals, supplemented by GPS signal offers the user more security in data analysis and interpretation. Modern data interfaces enable the uncomplicated integration into digitalized process chains.

On the basis of AI-supported algorithms, the SRE can support the inspector in the evaluation process via pre-classification. Each indicator evaluated by the inspector without contradiction increases the performance of the pattern recognition and improves over time both the condition-based maintenance and the measure evaluation using methods of machine learning. With the help of an asset management program, the informative value of the AI-supported forecasts on wear development or service life can be increased.

Matured design

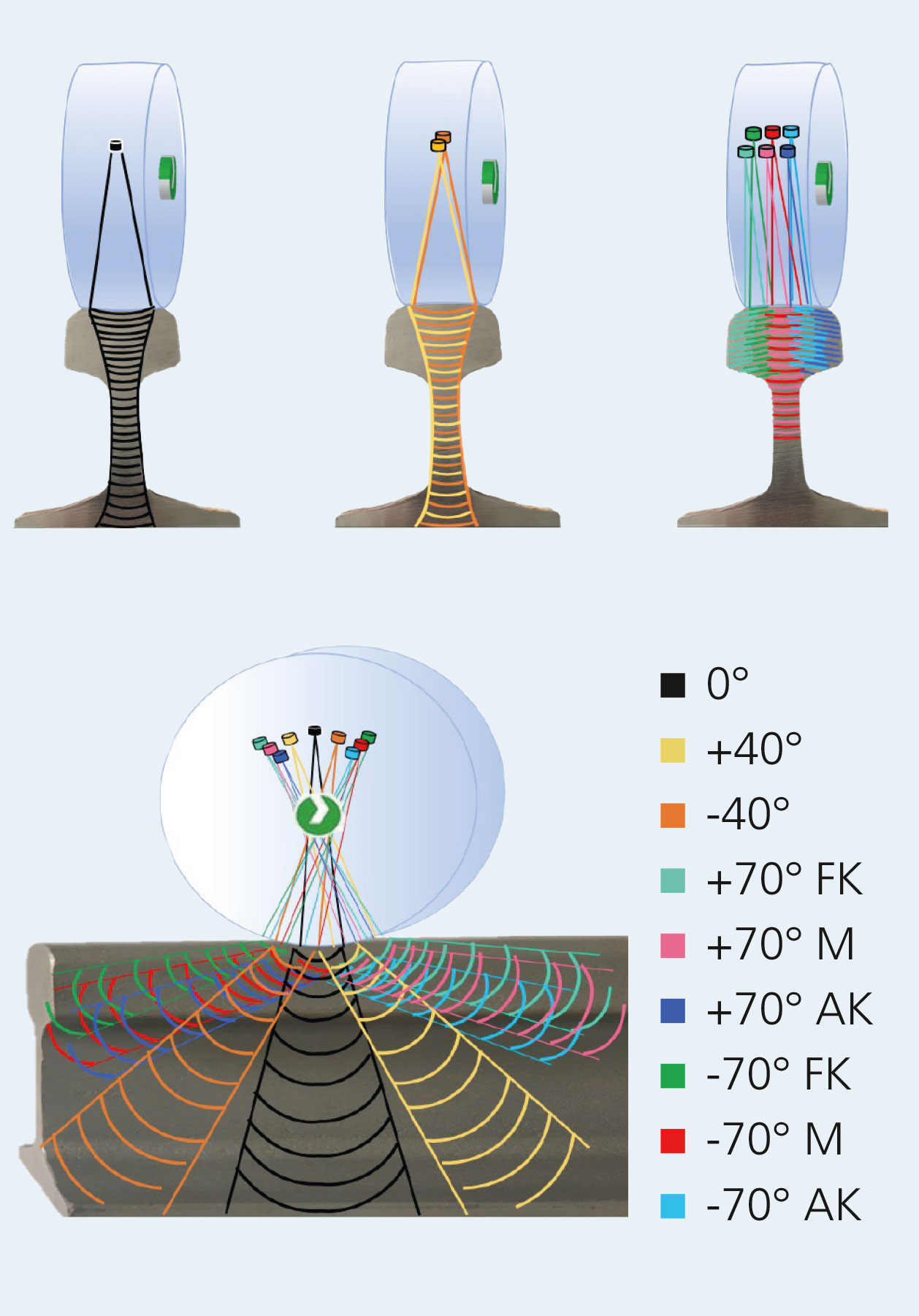

With an inspection distance of up to one millimeter, the total of nine probes (0°, ± 40°, ± 70° in the middle, driving and outer edge) both identifiable near-surface irregularities and volume defects in the head, web and foot of the rail according to DIN EN 16729-1 in real time. The findings are visualized to the user synchronized as both A-scan and B-scan as soon as the recording limit is reached. In parallel, extensive raw data can be accessed in support.

With the amplitude-based volume view, the user can – in contrast to the classic aperture technique – subsequently edit the threshold value himself and thus obtain even more revealing information about the reflectors and their dynamics.

The ultrasonic inspection wheel is adapted to the rail profile to be inspected via the permanently rotating lateral guide rollers and reliably positioned above the rail middle. Thereby differentiates the guide system between forward and reverse operation and automatically aligns the stabilized slight inclination of the track rollers with a servo motor.

With its features, the SRE offers a wide range of possible uses that go far beyond simple ultrasonic testing.