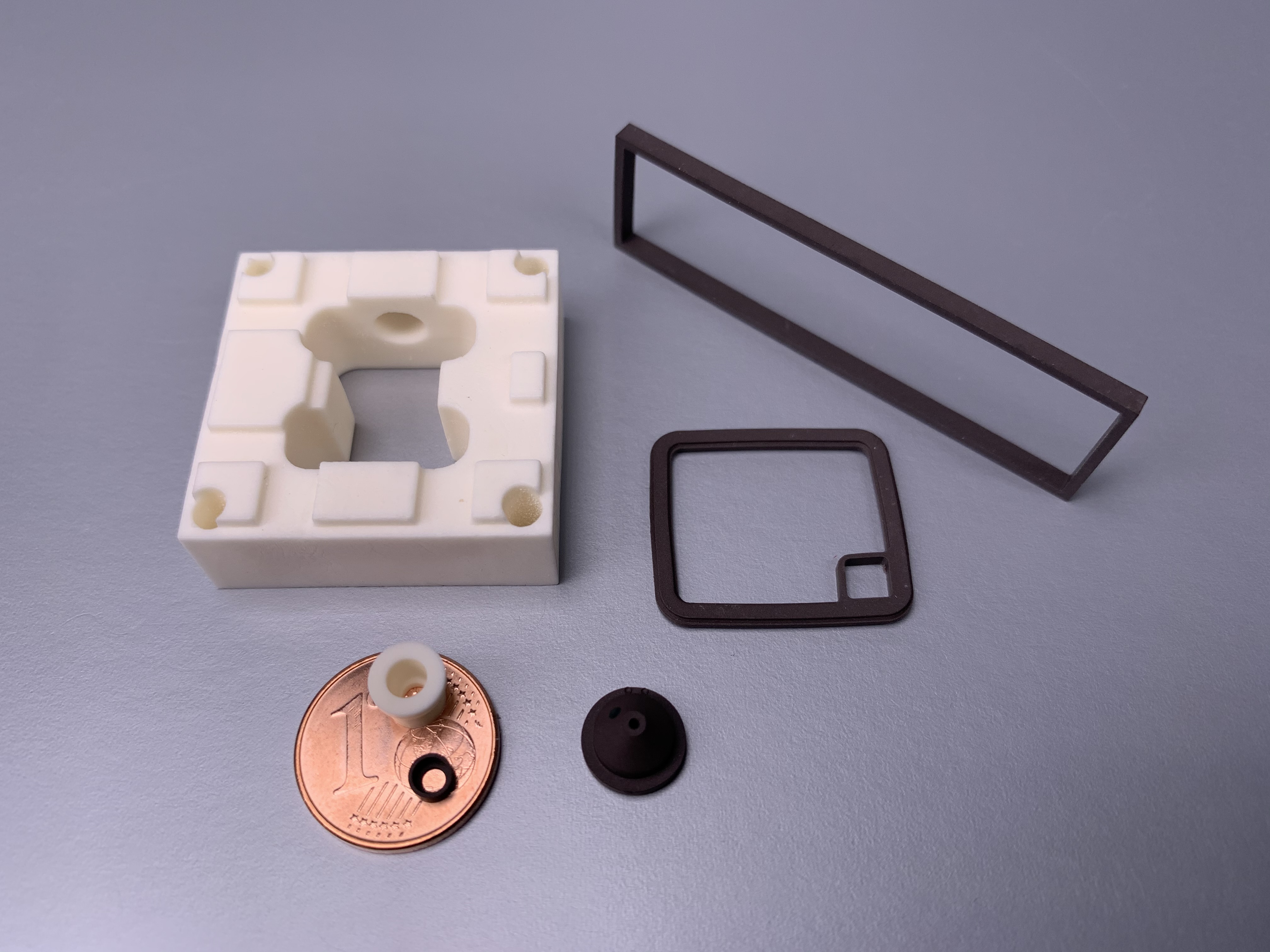

Oxide ceramic components manufactured by low-pressure injection molding.

Plane parallel hard machining (lapping) of high-purity Al2O3-membranes for pressure sensors.

In addition to the development and optimization of oxide ceramic materials, Fraunhofer IKTS has outstanding expertise in the field of sample and small series production. This includes sensor components as well as complex shaped oxide ceramic components for use in microelectronics and textile technology. In order to meet the specific requirements of these industries, IKTS can rely on closed process chains under low-contamination conditions.

Services offered

- Uniaxial dry pressing

- Low-pressure injection molding

- Plane parallel final machining (minimum component height 100 µm)

- Customer-specific prototype and small series production of oxide ceramic and high-purity oxide ceramic components, highly pure oxide ceramics can be produced under low-contamination conditions

Technical equipment

- Preparation technology (dispersing, grinding, spray granulation)

- Uniaxial dry pressing (hydraulic and electrical)

- Hot mixer and low-pressure injection molding machine

- Thermal treatment (debinding and sintering technology)

- Final machining (grinding and lapping)