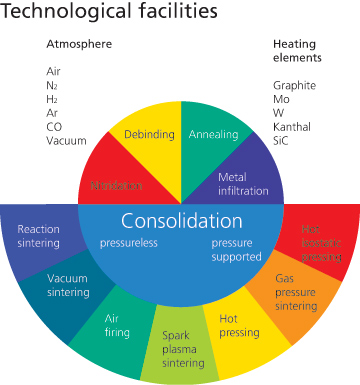

The working group develops customer-specific solutions for the heat treatment of ceramic and metallic materials and components. The materials properties and chemical composition of those materials significantly define the selection of appropriate furnaces as well as the necessary process atmosphere.

For these tasks, 40 different furnaces are available at Fraunhofer IKTS for:

- Debinding (under air, catalytic, by different solvent)

- Pyrolysis

- Sintering (reaction sintering, melt infiltration, gas pressure sintering, hot pressing, FAST/SPS)

- Annealing and tempering

Our furnaces are equipped with graphite, tungsten, Kanthal, Superkanthal or metallic heaters and can be operated over a wide range of temperatures up to 2600 °C, at different gas pressures from 10-8 up to 2*106 mbar (2000 bar) using different mixable process gases (N2, Ar, N2/H2, Ar/H2, O2, CO, H2, CH4). Thus, development work on samples and component can be conducted, and thermal processes can be transferred to pilot-plant scale. In order to design these processes stably, economically and cost-efficiently, all work is accompanied by in-house characterization possibilities.

Services offered

- Technology development for the debinding/pyrolysis and sintering of different materials

- Process design, upscaling and optimization of heat treatment processes

- Prototyping and small-series production

- Process design for batch production

- Consultation for quality assurance of thermal processes

- Research and technological services regarding thermal treatment processes of ceramic and powder metallurgical components and composites

Technical equipment (extraction)

| Debinding furnaces | up to V = 500 l | T = 1200 °C | p = 1 bar | Air |

| Pyrolysis furnaces | up to V = 550 l | T = 1400 °C | p = 1 bar | Vac., N2, Ar |

| Air furnaces | up to V = 500 l | T = 1800 °C | p = 1 bar | Air, O2 |

| Vacuum/gas furnaces | up to V = 550 l | T = 2600 °C | p = 10-6 to 1 bar | Vac., N2, Ar, H2, CH4, CO |

| Gas pressure sintering furnaces | up to V = 50 l | T = 2000 °C | p = 100 bar | N2, Ar |

| Hot isostatic presses | up to V = 30 l | T = 2000 °C | p = 2000 bar | N2, Ar |

| Hot presses | up to Ø 220 mm | T = 2200 °C | p = 50 MPa | Vac., N2, Ar |

| Hybrid-heated FAST/SPS | up to Ø 100 mm | T = 2400 °C | p = 50 MPa | Vac., N2, Ar, Ar/H2 |