BMWI funds development of oxyfuel combined heat and power plant for CO2 capture

The use of combined heat and power (CHP) units has been promoted for decades because they generate both electricity and heat on site as required and can therefore make optimum use of the energy content of fuels. As with all combustion processes, however, this produces CO2, which contributes to global warming.

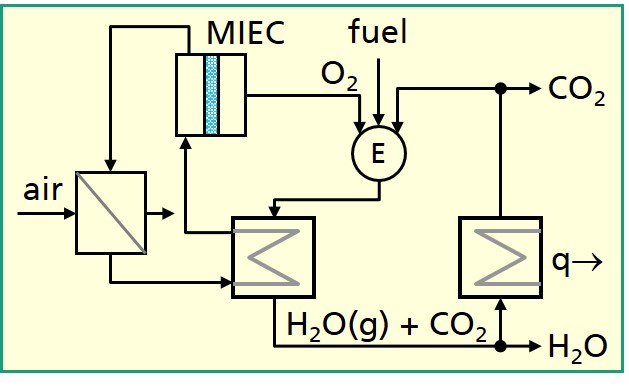

In the joint project "OGiS" – Oxyfuel gas engine with integrated oxygen generation for CO2 separation, which the German Federal Ministry for Economic Affairs and Energy is funding over a period of three years with around € 1.2 million, the CHP engine is to be operated with oxygen instead of air. After condensation of the water vapor, the exhaust gas then consists of almost pure CO2, which can then be converted back into synthetic fuels using water and "green" electricity.

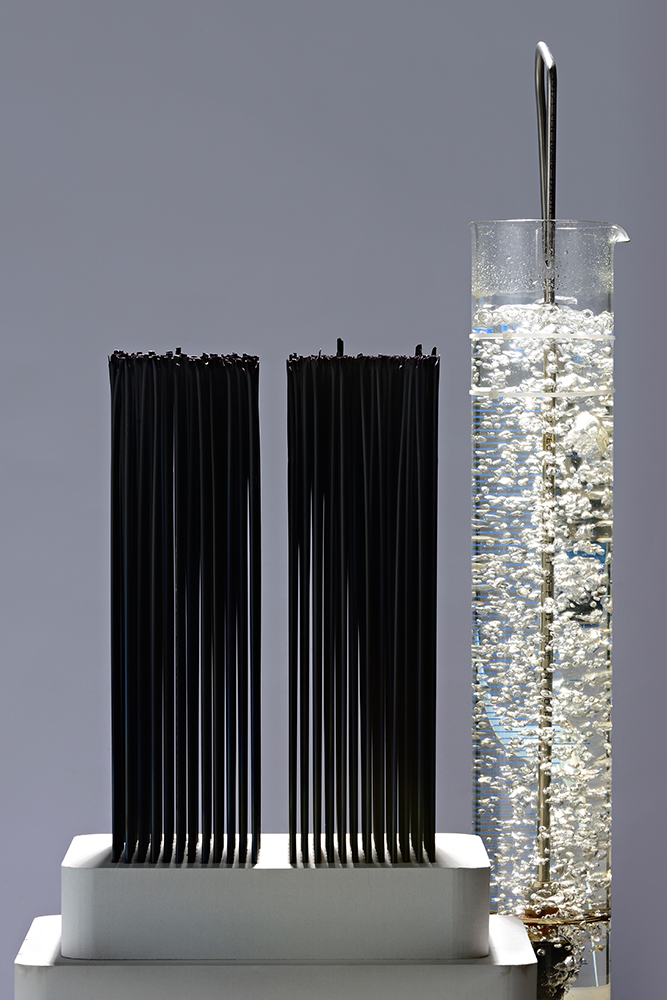

As part of the project, Fraunhofer IKTS will develop ceramic MIEC membranes (MIEC – Mixed Ionic Electronic Conductor), which generate the required oxygen locally using a motor. Despite some additional energy required for O2 separation, the consortium (Fraunhofer IKTS, regineering GmBH Preith, TAD GmbH Oranienbaum) even expects an increase in the electrical efficiency of the overall system, since an increased O2 content increases the Carnot efficiency. The Carnot factor describes the highest theoretically possible efficiency in the conversion of thermal energy into mechanical energy. In addition, engine combustion can be optimized in the planned process without regard to NOx emissions, since no atmospheric nitrogen enters the combustion process.

This is the first time that a CCS (Carbon Capture and Storage) process has been proposed which is not expected to require any additional energy for CO2 capture. If successful, it could serve as a basis for energy storage systems with significantly higher overall efficiency and lower technical complexity.