The "Ultrasonic sensors and methods" workgroup of Fraunhofer IKTS at the Dresden Klotzsche site is in charge of methodical planning and simulation-based optimization of ultrasonic-based test methods as well as their implementation in devices and equipment. The latter is done primarily based on the institute’s own PCUS® pro-Plattform. The devices and software of the PCUS® pro family are developed by the groups "Electronics for testing systems" and "Software for testing systems". If required, highly sensitive and reliable ultrasonic probes and sensors for special applications complete the platform. These are designed and manufactured in the institute’s own lab.

Ultrasonic Sensors and Methods

Group

Design and optimization

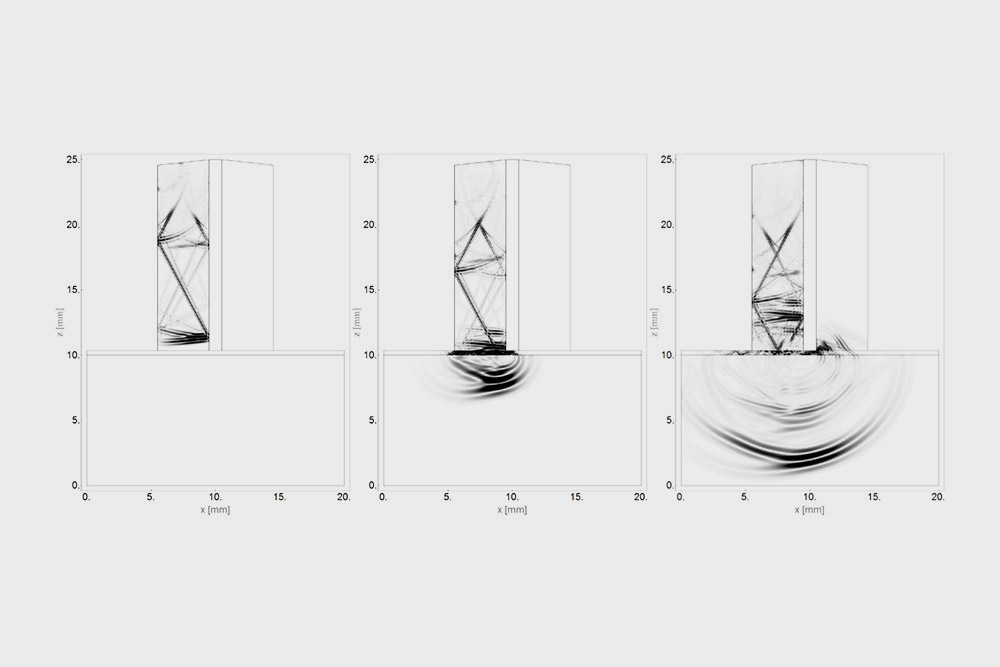

The complexity of novel materials and components implicate that simulation-based planning and optimization of probes and the continuous adaptation of test methods are gaining in importance. The complete test sequence including sensors can be simulated beforehand on the computer. The purpose is to test the set-up for physical plausibility and sensitivity and make the manufacturing process more economically efficient.

When development times are short, modeling and simulation help to avoid bad planning and enable a systematical optimization of test parameters. With this aim in mind, the »Ultrasonic sensors and processes« workgroup has for many years been developing its own high-performing computing programs and imaging analysis algorithms. These are available in a module library which can be extended in an efficient way and quickly adapted to suit new test requirements and tasks.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyDevelopment of specialized ultrasonic methods and transducers.

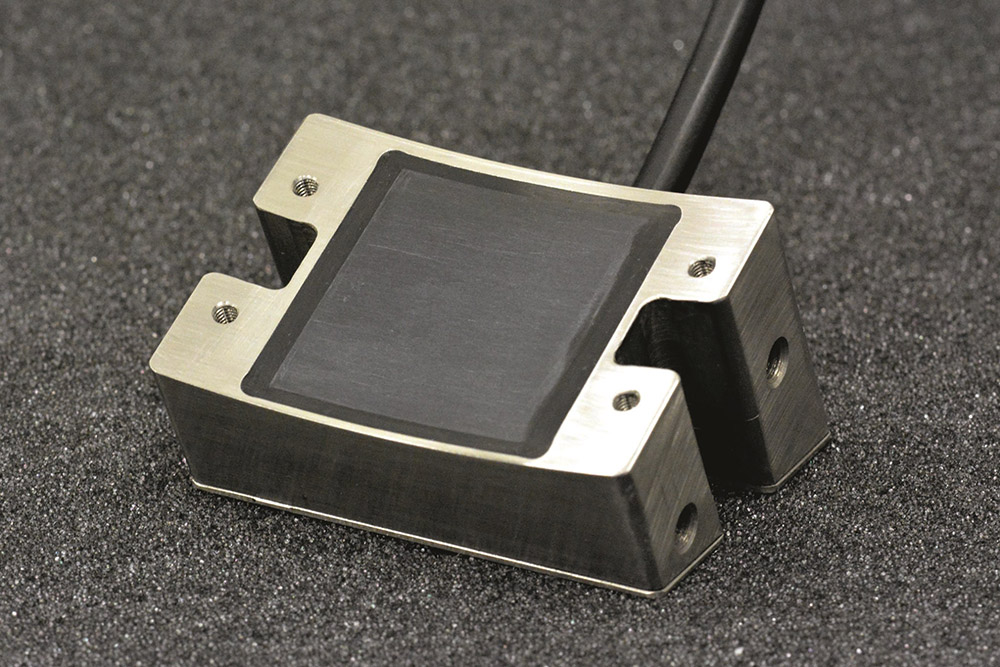

Development of specialized probes

Where commercially available probes are not suited for specific applications, the sensor lab of IKTS is able to design and manufacture customized ultrasonic transducers. High-performance simulation tools and equipment such as a dicing saw, d33 meter (piezometer) and HF pulser-receivers up to 500 MHz are available for this purpose.

Some examples for specialized applications are high-temperature sensors, high-frequency aluminum nitride thin-film transducers, curved piezocomposite probes as well as highly sensitive transducers based on piezoelectric monocrystals, such as lead magnesium niobate/lead titanate (PMN-PT). The available transducer types are single-element transducers, phased-array sensors, acoustic emission sensors and transmit/receive probes. They can be adapted for special component geometries and integrated in test pliers.

System development

The "Ultrasonic sensors and methods" workgroup realizes and coordinates the full integration of methods and algorithms in client-specific hardware and software. The group is also in charge of converting test methods into equipment, down to the construction of industrial prototypes in Germany and abroad.

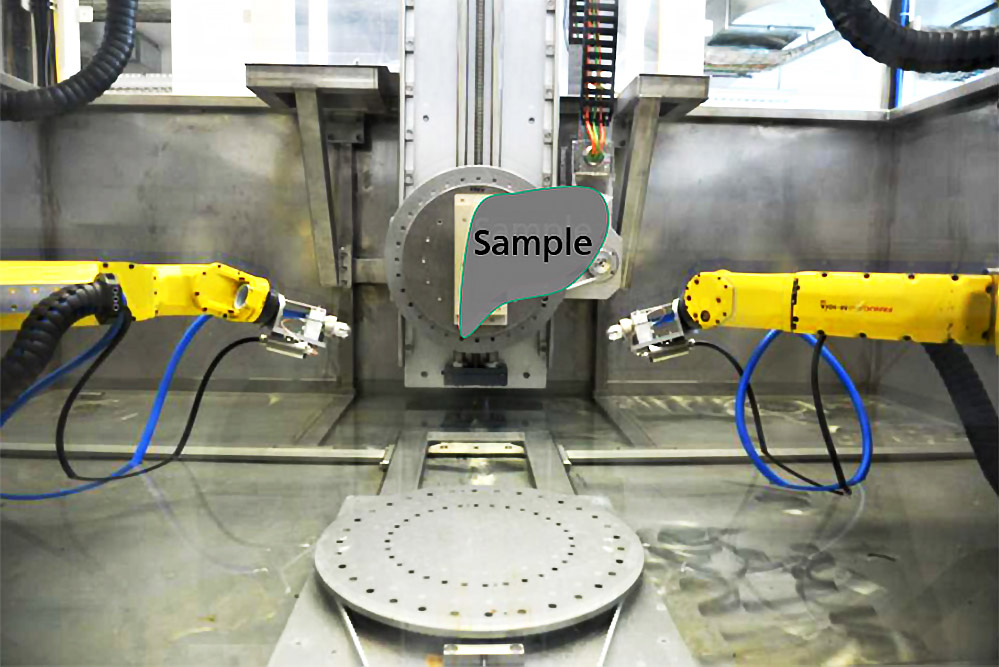

The group currently focuses on developing special high-resolution scanners and robot-based testing systems for free-form components with complex shapes and of various material classes.

Service portfolio

- Basic research and feasibility studies

- Development of methods and simulation-based optimization

- Development of (imaging) analysis algorithms and application-specific simulation tools

- Development and manufacture of ultrasonic transducers for special applications

- Manufacture of application-specific sensor materials (1-3 composites) based on PZT and PMN-PT

- Manufacture of client-specific acoustic stacks

- Characterization of piezoactive materials using d33 meter (piezometer)

- Electric and acoustic characterization of ultrasonic probes

- Development and design of high-resolution ultrasonic scanners

- Realization of complex automated robotic test facilities

- Inline and offline test solutions based on our proprietary PCUS® pro platform

- Licensing models for industry clients

- R&D cooperation with companies and research institutions

Range of equipment

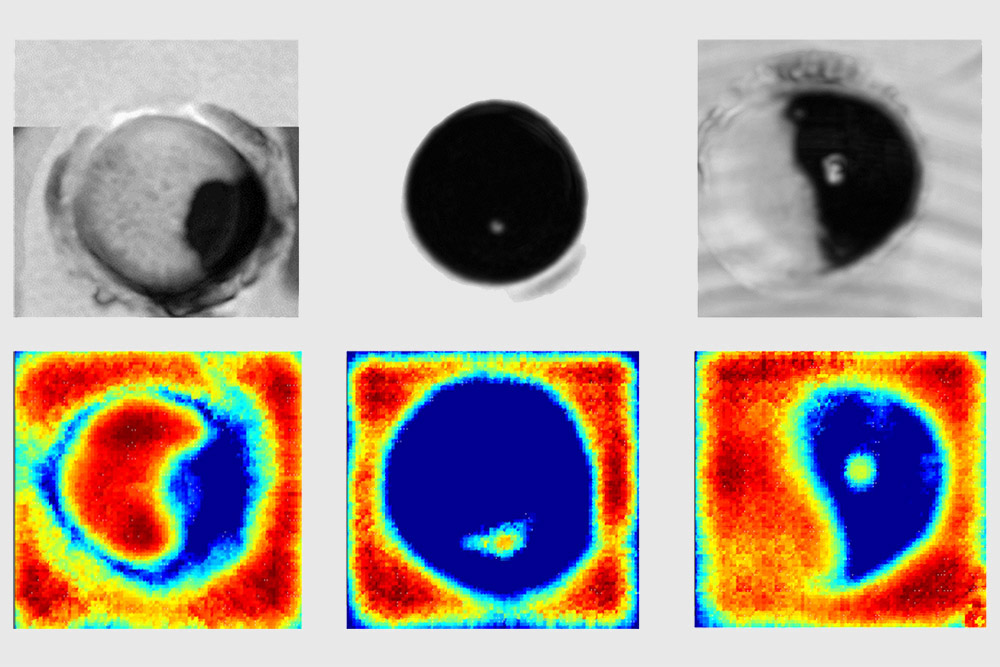

- Scanning acoustic microscope (SAM) for frequencies up to 400 MHz

- High-resolution scanner for ultrasonic and laser ultrasonic applications up to 100 MHz (self-built)

- Ultrasonic goniometer for surface characterization (self-built)

- Laser Doppler vibrometer for measuring sonic fields

- Dicing saw

- High-precision face grinding machine

- d33 meter (piezo testing)

- PCUS® pro ultrasonic hardware platform (single, multi, phased-array, HF)

- HF pulser-receiver, up to 500 MHz

- Air ultrasonic test facility (self-built)

- Measuring station for controlled charging and discharging of rechargeable battery cells and for acoustic measurement of battery cells and extrudates

- Ultrasonic spectroscopic measuring station for frequency-dependent characterization of liquids and solid bodies

- Temperature-controllable water bath up to 60 °C, with scanning device

Industrial solutions

- Simulation-based design and optimization of transmit/receive transducers [PDF | 1.0 MB]

- Studies and measurements with ultrasonic microscopy as service [PDF | 219 kB; p.2]

- Manufacturing of ultrasonic probes based on PMN-PT

- Development of an ultrasonic goniometer for characterizing surface-hardened components [PDF | 1.3 MB; p.2]

- Development of a high-resolution ultrasonic scanner for characterizing ultrasonic probes

- Development of ultrasonic phased-array pliers for the inspection of folded adhesive joints

- Determination of sound velocity and thickness of unknown solid and hollow bodies using ultrasonic waves [PDF | 1.5 MB; German] [Video]

- Ultrasonic testing system for crack detection on compression joints of railway catenary lines

- Inline monitoring system for the inspection of laser-welded seams [PDF | 1.0 MB]

- Characterization of biological samples using ultrasonic spectroscopy

- Thematic brochure: Ultrasound [PDF | 7.0 MB]

- Testing of filling and wetting processes in battery cell production [PDF | 1.3 MB]