Preliminary research for new battery systems

Temperature measurement during operation

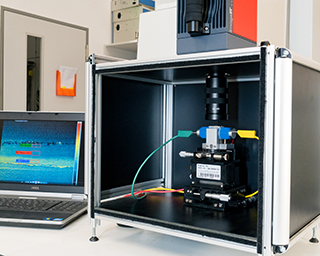

Current challenges concerning heat generation in lithium-ion batteries can only be met with a comprehensive understanding of the heat-generating processes and mechanisms on a microscopic scale. A special measurement setup was developed to allow for localized temperature measurement across the anode-separator-cathode interfaces in a model lithium-ion battery cell during battery operation with very high lateral resolution. The three-dimensional temperature distribution for defined charge and discharge currents can be reconstructed with the additional detection of the axial temperature gradient.

Unlike the usual integral measurements used for commercial battery systems, this allows heat sources and sinks in the electrochemical system to be located, identified, and differentiated between. With localized temperature measurements during operation in combination with advanced electrochemical techniques, light is shed on the complex relationships between the kinetics and the thermodynamics of the individual cell components and the resultant localized heat generation. Based on these findings, mechanistic models are developed and put into the modeling and simulation of the thermoelectrochemical behavior of lithium-ion batteries to form the basis for optimization of the materials with respect to thermal safety aspects.

Related Links

High-energy-cathode

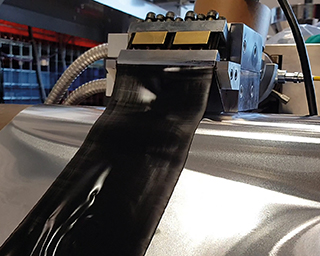

One of the central goals of current development efforts is to increase the energy storage density of lithium-ion battery cells, mainly to satisfy the requirements for use in automotive applications. The primary approach taken to achieve this is to optimize the cathode structure and, because it serves as the lithium supplier to the cell, its storage capacity. Optimized cells currently have a capacity per unit area of about 4 mAh/cm2. This is achieved by using active materials of high storage density combined with increased electrode packing densities. Mass per unit area and electrode density are hence the levers with which storage density-optimized electrode designs are realized. However, restrictions are coming from the processability in downstream cell manufacturing processes (mechanical requirements, electrolyte filling duration) and cell performance during operation (especially rate capability limitations due to limitations in lithium-ion diffusion).

The work of Fraunhofer IKTS deals with laboratory- and pilotscale extrusion-based deposition techniques, whereby both classic extrusion processes with solids contents of 90 % from ceramics technology and slot die coating with solids contents of 50–70 % show great technological potential.

Related Links

Solid-state battery

Lithium-ion batteries with solid-state conductors and lithium-metal anodes are treated as promising next-generation storage technologies due to their higher specific energies as well as their favorable safety aspects.

For many years now, Fraunhofer IKTS has been striving to develop lithium-conducting glasses and solid electrolytes and to integrate these components into the cell assembly. The aim is to derive suitable process technologies for the production of all-ceramic solid-state batteries (in particular composite cathodes and solid electrolyte separators).

The core elements of this are realization of a defect-free, stable electrolyte separator (avoidance of dendrite growth on the lithium-metal anode), compensation for thermomechanical stresses in the composite cathode and in the electrolyte (volume compensation by active material, adjustment of thermal expansion coefficients), and production of a composite cathode with a low residual porosity and with simultaneous avoidance of damaging secondary reactions between the active material and the ionic conductor. To that end, development of manufacturing processes and investigation of suitable combinations of active materials and ionic conductors as well as optimization of grain structures, surface structures, and microstructures are necessary.