Materials and Components

Department

The “Materials and Components” department is involved in the development and preparation of functional ceramic materials and their application in functional elements.

Traditional fields are thick film technology, glass development, high-temperature fuel cells (SOFCs), and high-temperature chemical sensors. Extensive experience and outstanding technical equipment allow complex requirements and interactions in sophisticated applications such as fuel cells, lithium ion batteries and supercaps, sensors, microsystems, and packaging in complex materials systems to be controlled. At the Dresden institute branch, screen printing pastes, inks, and slurries are developed to be used in electrochemical components and microsystems.

Materials development in combination with different coating methods – especially for applications in electrochemistry and joining technology – form the basis for the development of new components (SOFC/SOEC, thermoelectric generators, sensors).

Close meshing with the “Modules and Systems” and “Industrialization Systems” departments ensures the practical relevance of the results. This allows us to give our customers attractive offers for materials, prototypes, and services along the entire process chain.

Services offered

- Development and preparation of pastes for screen printing, dispensing and roll coating as well as their pilot plant production

- Development and preparation of nanoinks for ink-jet and aerosol jet printing

- Development and preparation of sealing glasses and elements as well as solders

- Glass development for specific applications

- Development of electrode materials and coatings for lithium ion batteries and supercaps

- Testing and inspection capacity for materials and functional high-temperature components for gas sensors, SOFC/SOEC and thermoelectric generators

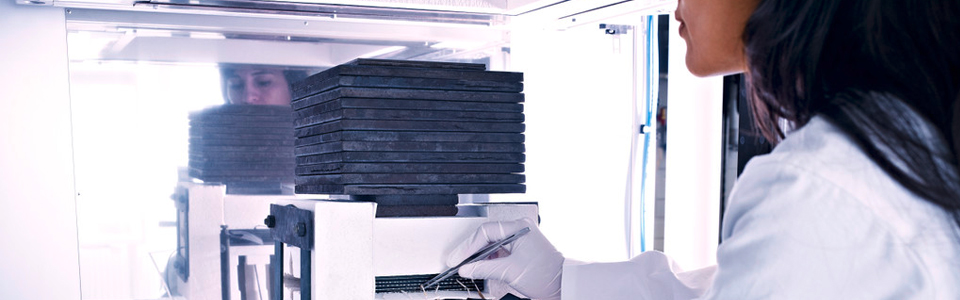

- Development, manufacture, and testing of SOFC stacks

- Packaging for ceramic systems

- Consulting and materials analysis

Special equipment

Complete technology lines for

- Paste preparation from functional materials, especially for thick film technology and inkjet printing for application in sensors, SOFCs, Li-ion batteries, and supercaps as well as in solid oxide electrolyzer cells (SOECs)

- Characterization and preparation of glass solders, active solders, and composites in the form of thick film pastes or films for high-temperature applications (SOFCs, SOECs, oxygen permeation membranes)

- Coating technologies: screen and mask printing, inkjet and aerosol printing, dispensing, wet powder spraying, and slip casting

- Systems for firing and soldering (including induction soldering) in vacuum, argon, hydrogen, and air

- Materials and component characterization

- Accompanying process control via QA certified in accordance with ISO 9001:2015