Material development for lithium-ion batteries

Powder synthesis and preparation

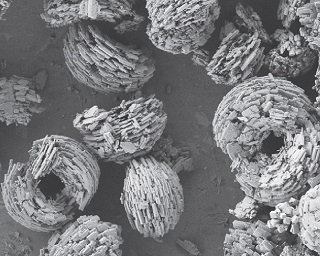

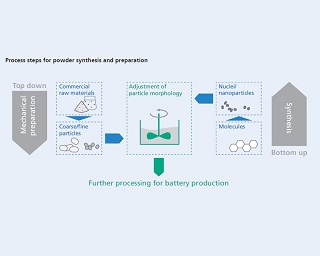

Development of competitive lithium-ion batteries starts with the synthesis and preparation of tailored powders (active materials, ceramic electrolyte and separator materials). As cathode costs constitute around a third of the overall cell material costs in the current generation of lithium-ion batteries, demand-specific, scalable synthesis routes are essential for lowering costs. In addition, the production methods are key to achieving further increases in specific storage capacity, cell voltage, power density, and service life. This in turn requires precise control of particle size and morphology. At Fraunhofer IKTS, two process routes are taken. With the top-down approach, commercial powders are reduced to the desired size using mechanical preparation processes and are then classified. In the bottom-up approach, particle size, distribution, and morphology are already adjusted to the appropriate levels during synthesis of the primary particles (0.1–50 μm).

Besides the classic solid-state reactions and spray drying-based methods utilizing precursor compounds, sol-gel methods under normal pressure as well as hydrosyntheses and solvothermal syntheses with microwave-assisted reactors are employed. High purities and inert process conditions are required for the resultant primary particles to be processed to yield homogeneous powders with well-defined functionalities. For the production of active mixtures, powders with precisely defined granule morphologies, sizes, and compositions as dictated by the respective applications, e.g., for high-power and high-energy electrodes or for solid-electrolyte cell concepts, are needed.

Fraunhofer IKTS offers all processes for modification, tailoring, and characterization of the properties of battery powders (5–100 μm) and their chemical precursors. With the equipment and experience available at Fraunhofer IKTS, small quantities of up to one kilogram to pilot-scale quantities of several hundreds of kilograms can be handled.

Related Links

Acompanying analytics

Microscopic materials behavior, aging, and degradation as well as the influence of the production technologies exhibit mutual dependencies throughout the entire battery development and production process. Hence, measurement-assisted evaluation of the powder-based battery components over the course of the process delivers useful information for targeted process analysis, monitoring, and optimization.

At Fraunhofer IKTS, state-of-the-art equipment and a comprehensive portfolio of highly modern analysis methods are available. Apart from standard analysis methods, such as FESEM, TEM, XRD, EDX, Raman spectroscopy, and IR spectroscopy, a number of special techniques can be used. In the last few years, Fraunhofer IKTS has established ion beam-based preparation methods (FIB/BIB) that enable delicate samples, such as granules, electrodes, or pre-sintered components, to be prepared in such a way that the internal structures and the microstructure can be imaged with high resolution and no artifacts. Thus, it is possible to visualize the distribution of solid materials and organic components like binder over the sample cross section. With this information, process technologies can be optimized and degradation mechanisms investigated.

Direct transfer of samples in a protective gas atmosphere from the glove box to a scanning electron microscope or an X-ray diffractometer for subsequent analysis is also possible at Fraunhofer IKTS. Reaction of the materials with air and the resultant changes of material properties are thus prevented.