Condition monitoring

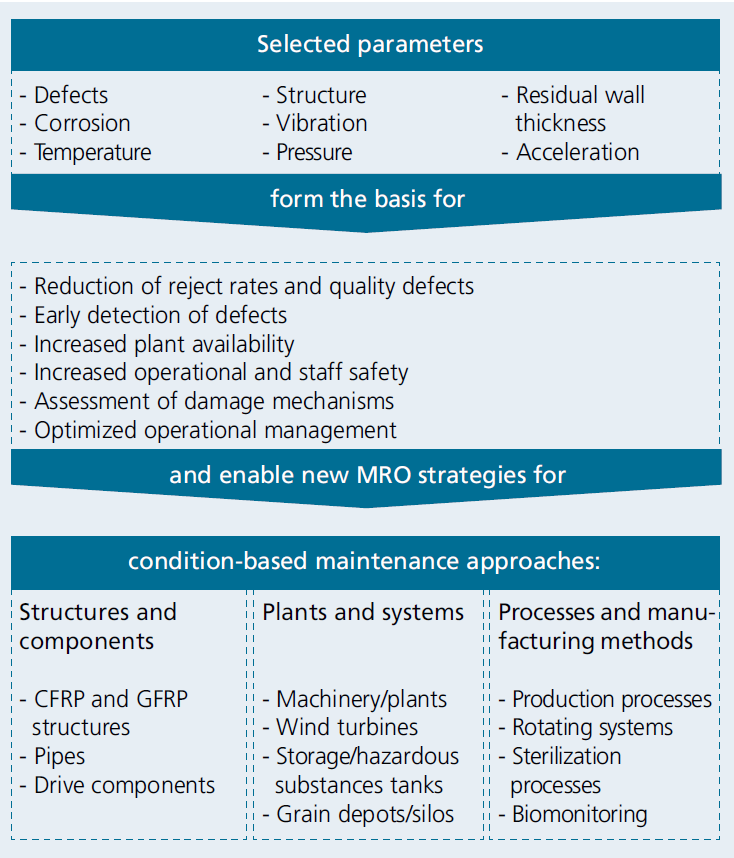

Methods and measuring systems for condition monitoring (CM) ensure the availability of plants and machinery. The regular collection of machine conditions and states can provide decisive information needed for maintenance, repair and operations (MRO) strategies, for better control and optimized processes. Static components, by contrast, can be monitored automatically with structural health monitoring (SHM). SHM detects and assesses damage mechanisms and ensures the reliability and optimal function of critical components.

Improved reliability, reduced costs

Fraunhofer IKTS is a competent partner when it comes to monitoring materials, components, assemblies, plants and machinery as well as the pertaining manufacturing methods. This includes the analysis and assessment of components and processes, as well as their optimization.

For this purpose, IKTS develops sensors (optical, acoustic, electromagnetic), systems and techniques for condition monitoring, which are implemented while plants are being built and taken into operation. These systems can also be installed in existing infrastructures. They are designed for harsh conditions and offer tools for the non-destructive detection of defects, real-time monitoring and, associated with this, condition-based maintenance or optimization of plants.

The customized solutions help to improve plant safety in full compliance with all standards. They are developed in close cooperation with machine manufacturers and users.

Cooperation models

Innovation and development are the cornerstones of a promising corporate future. In order to create a competitive edge, Fraunhofer offers tailored options for cooperation, so that companies can work together in the best possible way. This also allows to utilize development skills at short notice and as needed.