Ceramic filters and catalysts play a key role in processes for exhaust gas after-treatment, water treatment and materials recovery – especially when it comes to high temperatures, chemical corrosion and durability. For this purpose, we develop and test application-oriented materials, components and processes. In the field of catalysis and particulate filtration, for example, we are working on new solutions for the aftertreatment of exhaust gases from engines in the non-road sector and on fine dust filters and catalytic converters for wood-burning stoves which, on the basis of porous and cellular ceramics, enable the limits of the Blue Angel to be achieved. Another example is modified DeNOx catalysts and oxidation catalysts for the reduction of short-chain hydrocarbons in exhaust gases from cement plants. State-of-the-art stationary and dynamic test benches are available at the Fraunhofer IKTS for investigating the operational behavior of particulate filters and catalysts. In addition, the characterization of particulate filters (DPF, GPF) and exhaust gas catalysts (TWC, DOC, SCR, ASC) in new and post-mortem condition is a major field of work of our group.

In addition to complying with increasing limits in connection with air pollutants, the recovery of valuable materials is also of great importance in incineration processes. In the field of sewage sludge incineration, we have designed and already successfully demonstrated a process in pilot plants that allows heavy metals to be separated from the waste gas stream by means of hot gas filtration. On the one hand, the recovered heavy metals can be recycled and, on the other hand, the sewage sludge ash can be used as phosphorus fertilizer in agriculture.

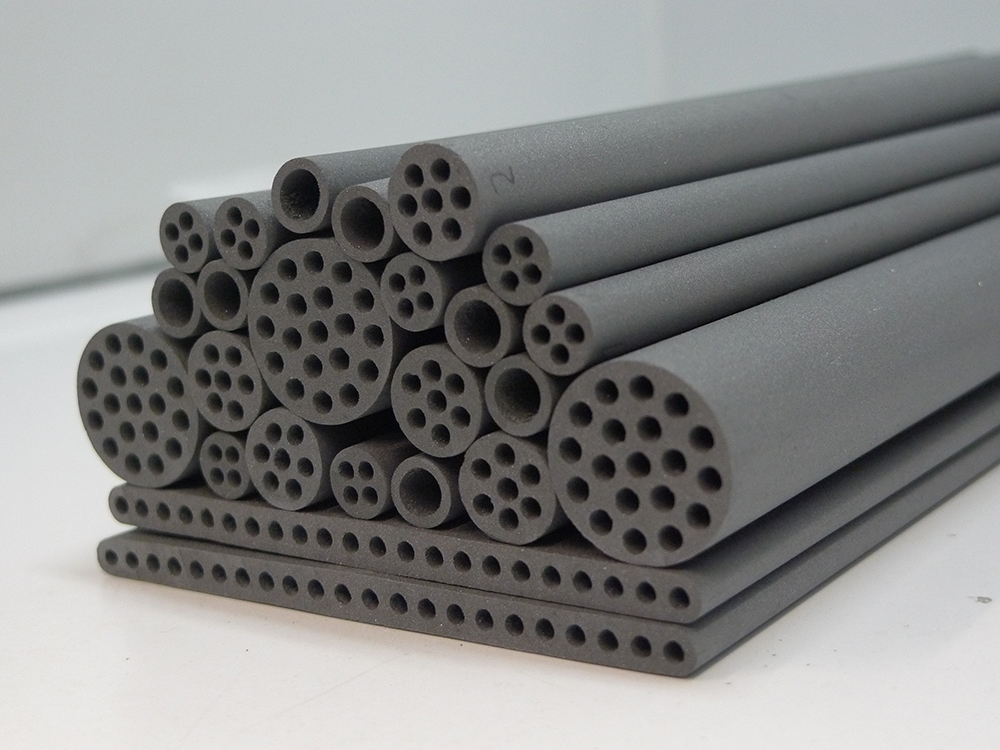

In addition to particulate filters and catalysts for engine and stationary exhaust gas purification, we are also working on membranes for micro- and ultrafiltration of wastewater. These special silicon carbide membranes are characterized by high permeability, mechanical stability as well as temperature and corrosion resistance and can be designed with different pore sizes and high open porosity (> 40 %). Another research focus is currently the hydrophobization of these membranes in order to be able to use them for carbon capture applications.

Services offered

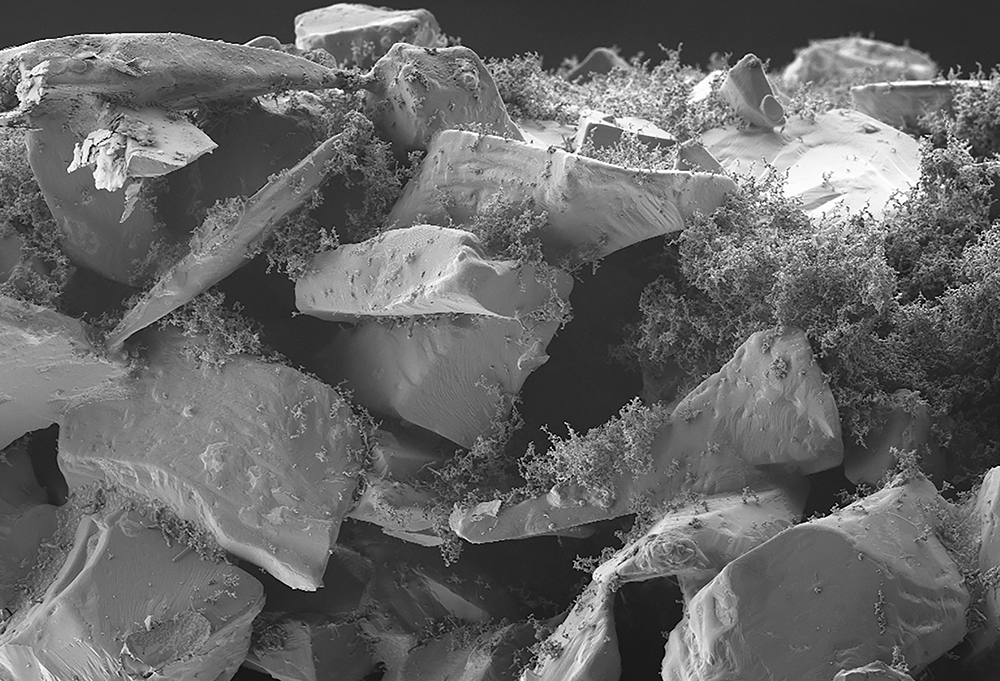

- Development, testing and optimization of materials for particle, liquid and hot gas filtration (silicon carbide, cordierite, aluminum oxide, ferrous and non-ferrous metals)

- Filter production from powder to component (sample and small series production)

- Catalytic and adsorptive coatings for the reduction of carbon monoxide, nitrogen oxides, hydrocarbons and other harmful gases

- Material characterization and component testing on hot gas test rigs, synthesis gas test rigs and membrane test rigs

- Post-mortem analyses of particulate and hot gas filters as well as catalysts and catalyst carriers