Equipment for production and evaluation of filters, catalysts

Semiautomatic plugging unit for filter segments.

Continuous multi-step system for foam coating.

Large centrifuge used to coat open-cell foam ceramics.

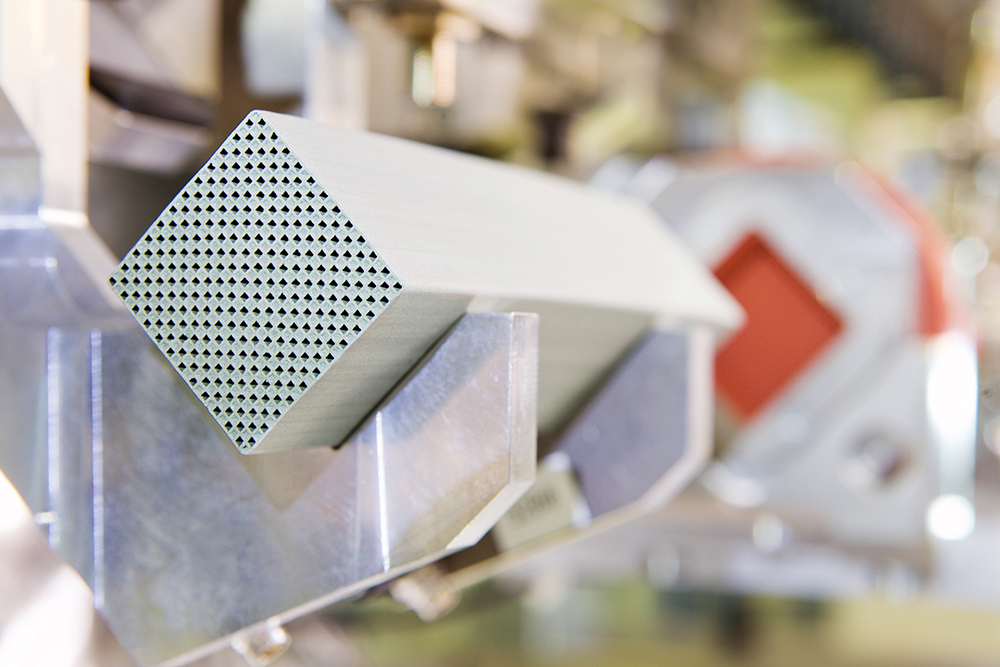

Extrusion of honeycomb and tube geometries

- Preparation with Eirich mixer and double-Z kneader

- Ram extruder and various screw extruders

- Various dies for honeycomb and tube geometries, individual dies are possible

Manufacture of open-cell foam ceramics following the Schwartzwalder method

- Semiautomatic impregnating unit for foam

- Single- and multi-step rolling unit for foam coating

- Centrifuges for foam coating

Calcination/heat treatment

- Air sintering furnaces, up to 1700 °C

- Inert gas furnaces, up to 2500 °C (Ar, N2, vacuum)

- Fast firing continuous furnace, up to 1100 °C (air)

- Hydrothermal aging unit, up to 650 °C, 10% H2O

Coating

- Immersion coating for individual segments and fine filter substrates

- Centrifuges of various sizes

Filtration test stands

- Sooting, back pressure and particle test stand for segments and filter discs (RT)

- Sooting, back pressure and particle test stand for filters up to 12’’ or industrial hot gas filtration up to 1000 °C (hot gas test stand), also for the endurance testing of filters or cyclical analyses of service life, drop-to-idle

- Back pressure measurements, up to 12 bar on small sample geometries (porometer)

- Pressure drop test stand for foam ceramics, up to 20 m/s

- Determination of cell width for cellular systems

Catalysis test stands

- Fully automatic chemisorption analysis unit (Autochem) for chemical and temperature-programmed reactions on powder samples

- Syngas test stands for the analysis and aging of honeycombs and core samples, static and highly dynamic heating and gas dosing regimes, synthetic gaseous mixtures (N2, O2, CO, NO/NO2, NH3, HC, H2O, SO2, CH4+C3H6, C3H8)

Testing of mechanical properties

- Compressive strength testing on filters, up to 10 bar

- Compressive strength testing for foam ceramics

- Compressive strength testing for honeycomb geometries in A, B or C direction

- Strength testing for honeycomb geometries according to ASTM C1674-08 at RT and < 1600 °C in air

- Determination of Young’s modulus

- Thermal stability and thermal shock resistance

Chemical Composition

- Elemental analysis (EDX)

- X-ray fluorescent analysis (XRF)

- Inductively coupled plasma atomic emission spectroscopy (ICP-AES)

- Qualitative and quantitative phase analysis (XRD) also with grazing incidence, from RT to 1400 °C

Characterization of particulate matter and suspensions

- Particle size distribution, particle shape

- Specific surface BET (N2/Kr adsorption and desorption)

- Pore distribution (Hg porosimetry, permeation porosimetry)

- Surface charge, zeta potential

- Rheology, viscosity

- Determination of density (bulk density, true density, pyknometry)

- Sedimentation stability

Microstructure and material characerization

- Materialographic preparation of samples (mechanical preparation, chemical and physical etching techniques, ion beam preparation)

- Microscopy (light microscopy, stereo light microscopy, scanning electron microscopy [REM/FESEM], transmission elec-tron microscopy [TEM], etc.)

- Coat thickness analysis

- Precious metal crystallites and particle size

- X-ray computer tomography

Thermal analytics and thermal physics

- Thermogravimetry (TG)

- Thermomechanical analysis (TMA)

- Thermodilatometry (TD)

- Thermal conductivity at RT

- Heat capacity

Modeling and simulation

- Finite element analysis (FEM), ANSYS (Emag/Mech), COMSOL Multiphysics, FlexPDE, Atila

- Flow simulation (Fluent)

- System simulation (Matlab/Simulink, Simulation X, Dymola/Modelica)

- Thermodynamic simulation (Factsage)

Accredited laboratories (DIN EN ISO/EC 1725)

- Thermal analytics and thermal physics

- Characterization of particulate matter and suspensions

- Laboratory for quality assurance and reliability