Air purification in domestic applications

Most people spend considerable chunks of their day indoors – whether at home, in transit or at work. Room air quality therefore plays an important role. Dust, bacteria and odors pose a threat to air quality. Foam ceramic filters for dust removal or ceramically supported photocatalysts for odor filtration can contribute to healthy indoor air quality and a beneficial room climate.

Heating

Fireplaces and small stoves used with wood or wood pellets or other renewable raw materials are legitimate alternatives to heaters running on conventional energy sources, such as oil or gas. Phase 2 of the 1st Federal Immissions Protection Ordinance came into effect in Germany on January 1, 2015. It limits the admissible emissions of fireplaces for single rooms (wood-burning stoves and tiled stoves) to 40 mg/m3 for dust and 1250 mg/m3 for carbon monoxide.

The use of foam ceramic filters allows to reduce the fine particulate matter emissions of fireplaces. The web-like, highly porous ceramic structure absorbs particles and pollutants without becoming clogged up. This works, above all, during firing up, when a lot of soot and hydrocarbons is emitted. Once a higher temperature is reached these pollutants are safely combusted in the filter. The installation of a foam ceramic filter directly in the stove above the flames ensures a self-cleaning effect without the need for interventions from the user, and without costly additional equipment.

An additional reduction of gaseous pollutants, such as hydrocarbons (HC) and carbon monoxide (CO) beyond this point can be achieved through the use of catalytic converters. These must be particularly well-suited for the operating conditions of the fireplace in order to achieve optimal results in reducing pollution. The temperature conditions occurring during the use of a fireplace are of particular importance for catalytic activity and aging resistance.

Filtration of odors

Emissions of gaseous odorous substances occur in many industrial processes and in private households. Above a certain, mostly very low threshold, they are perceived as a nuisance in the room and ambient air. In order to reduce odors effectively, and to safely remove and bind many types of contamination, adsorbents such as activated charcoal are frequently used in packing or fabrics. Using ceramic technologies, these can also be transformed into cellular formed components or applied to suitable ceramic substrates. This makes handling easier and improves specific application properties, such as the back pressure or regeneration behavior in high temperatures. In addition to activated charcoal, IKTS also develops and processes adsorbents that are similar to ceramics, such as zeolites or metal organic frameworks (MOFs). They provide better performance and more stable regeneration in specific applications.

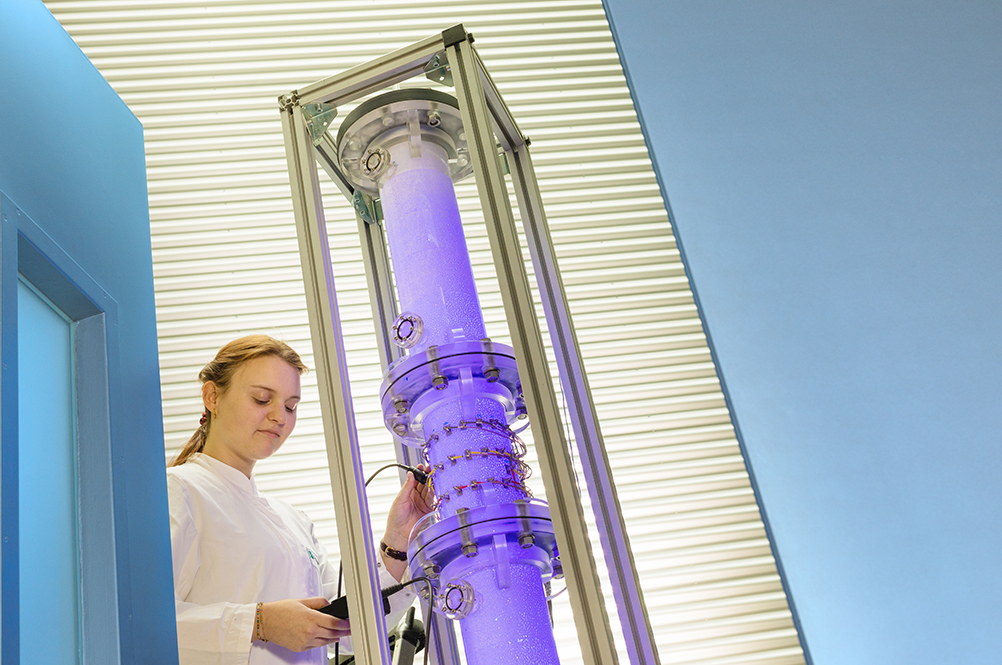

Photocatalytic converters are an alternative to adsorbents. When irradiated with natural or artificial UV light, radicals are produced on their surface which decompose organic substances and oxidize gaseous substances. Fraunhofer IKTS has the suitable technologies at its disposal to apply TiO2-based photocatalytic converters as layers onto cellular structures such as Al2O3, cordierite or SiC foam ceramics, or onto flat ceramic elements. The fact that this solution provides a large effective surface, in addition to its low back pressure, boosts the air-purifying effect. This means that frequent indoor pollutants, such as formaldehyde and acetaldehyde, can be converted into harmless compounds. Photocatalytic layers can also contribute to cleaner air in the interior cabins of vehicles and aircraft, or in private household applications, e.g. extractor hoods in kitchens. Furthermore, they have an antibacterial and antimicrobial effect and help prevent fungal growth.

Disinfection

Under certain conditions (depending on temperature and humidity), filters and air conditioning systems can contaminate the air with germs due to the number of bacteria and viruses in the air flow. Ceramic components with adsorbents and antibacterially effective surfaces can play a decisive role in disinfecting room air. Photocatalytically effective surfaces do not just help eliminate odors. They also contribute to a reduction of the bacterial load and boost the efficiency of UVC systems.