Competencies for production and evaluation of filters, catalysts

Development of particulate filters and catalyst supports, sample production

Material and technology development for the production of ceramic particulate filters and catalytic coatings on ceramic substrates (highly porous honeycombs and filter segments, open-cell foams, foam and catalyst pellets), design and optimization of particulate filters, sample and small-batch production

Selection of materials for substrates

- Silicon carbide (SSiC, LPS-SiC, RSiC, SiSiC clay-bonded SiC, glass-bonded SiC)

- Cordierite

- Alumina

- Zeolite

- Mullite

- Metal foams (steel, non-ferrous metal)

Catalytic and adsorptive coatings

Homogeneous, slip-based coatings and coating methods with defined coat thickness/loading through development and application of suspensions with adapted rheological properties

- Inner and outer coating

- Single- or multi-stage coating

- Immersion coating

Post-mortem analyses

- Soot load, soot analysis (physical)

- Ash load, ash deposits, ash analysis (chemical and physical)

- Post-mortem analysis of components and discrete samples (performance, mechanical, chemical)

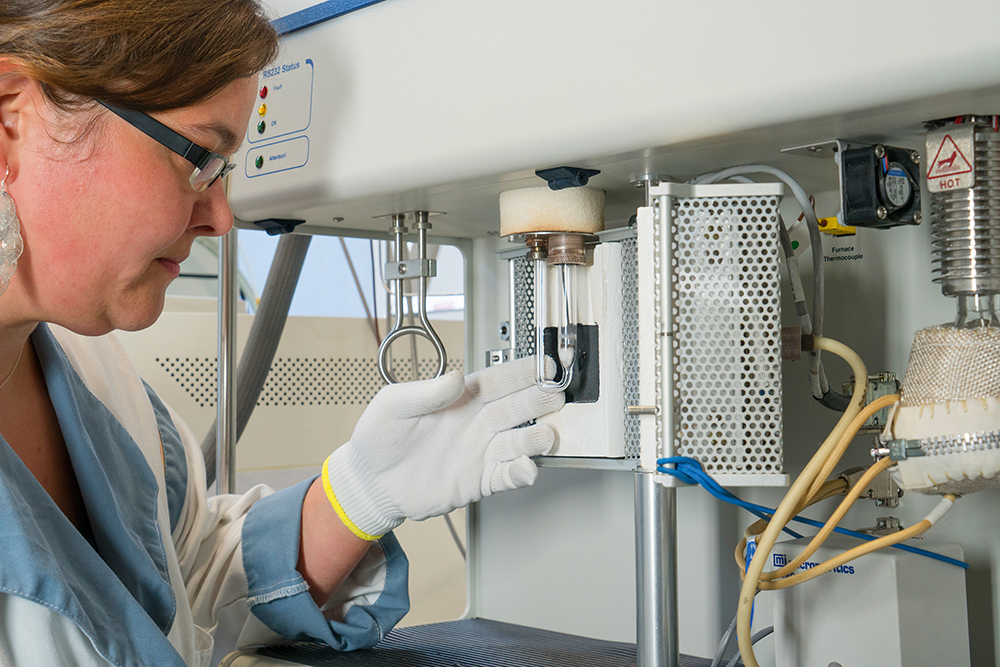

Material and component testing

Analytics for DeNOx catalytic converters (SCR, LNT, sDPF) and oxidizing catalytic converters (DOC, cDPF, TWC)

- Specific surface

- Macro- and microstructure

- Chemical composition

- Thermal stability

- Soot oxidation activity

- Catalyst dispersion (chemisorption)

- Catalytic activity (various syngas test stands, up to 900 °C, temperature-programmed desorption TPD, reaction TPR, oxidation TPO, NOx reduction)

- Life cycle assessment, forecast (hot gas test stand)

- Hydrothermal aging

Filter analytics

- Back pressure and filtration efficiency up to 1000 °C

- Pore size and pore size distribution

- Sooting, filter regeneration

- Particle separation capability

- Endurance testing at the hot gas test stand

Sensors

- Materials: Oxide and non-oxide ceramics, functional ceram-ics, polymer ceramics as powders, films, pastes and inks

- Technologies: Thin-film and thick-film technologies, packaging and joining technologies

- System integration