Materials and Processes

Profile

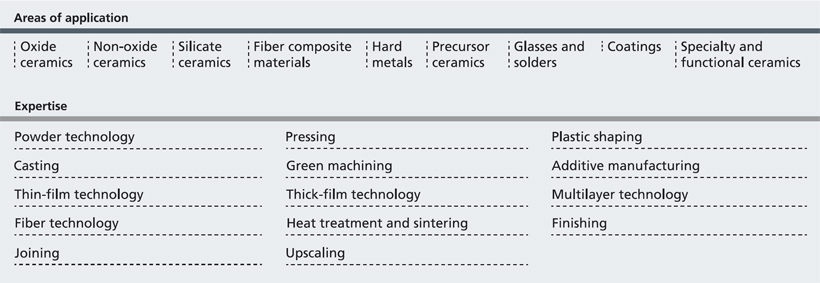

Fraunhofer IKTS‘s “Materials and Processes“ business division offers oxide, non-oxide and silicate materials as well as composite materials, glasses, hardmetals and cermets. Depending on commercially available raw materials and pre-ceramic preliminary stages, these materials are qualified for use in actual applications. They are the prerequisites to manufacturing prototypes and small-scale series (with ceramics custom-fit to the application), which are based on sustainable process developments.

New fields of application are unlocked by systematically linking structural features with the functional properties of ceramic materials and ceramic-metal composites. Concepts like these can be found in temperature-resistant materials, conductive ceramics, luminescent materials, transparent ceramics, polycrystalline abrasives and functional coatings, among other materials.

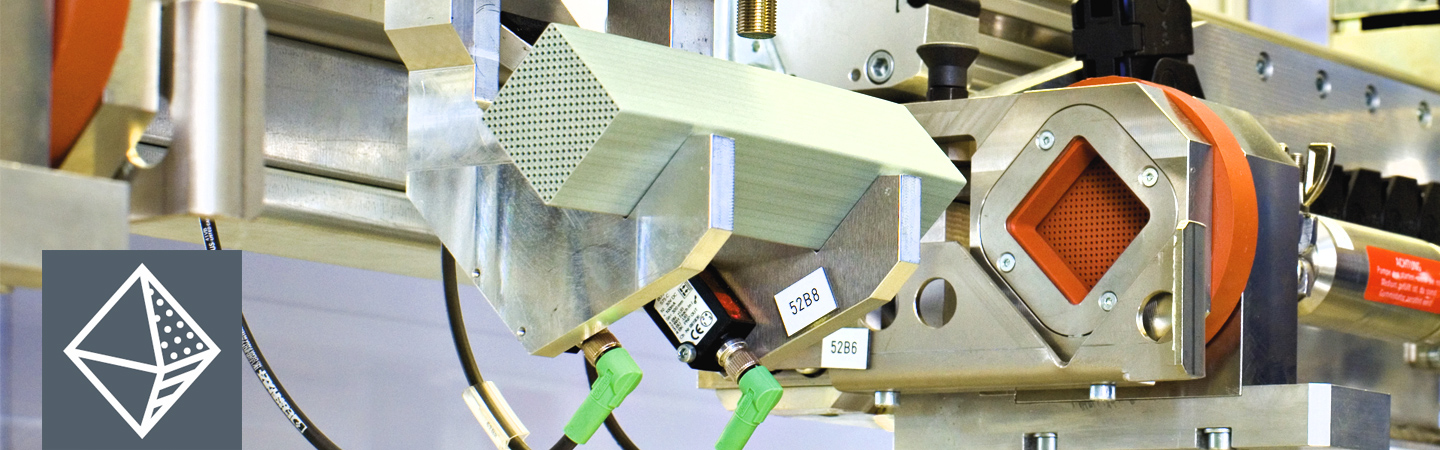

Fraunhofer IKTS sets the standard and continuously optimizes its powder technological manufacturing processes to keep them on the cutting edge in every respect – from the utmost purity to the maximum cost efficiency. This enables IKTS to establish the basis for materials and process engineering that parallels today‘s industries. It produces components and parts in multiple lines of technology. It is possible to upscale these products to small- and medium-scale series in-house on equipment and machinery suited for industry.

This broad spectrum of shaping services ranges from pressing, casting and plastic molding to additive manufacturing as well as multilayer technologies and direct printing processes. A large quantity of heat treatment methods, as well as the high-performance green machining and finishing reflects the comprehensive range of expertise and services covered by the Fraunhofer IKTS portfolio. With its expertise in coating processes – including chemical vapor deposition for example, or thermal spraying, surface level properties can be modified and components customized to individual specifications. Here as well, our customers benefit from the closed technology chains, which make it possible for IKTS to take a laboratory development to pilot-plant scale.

IKTS employees additionally possess the expertise honed by decades of experience in production-tailored and customer-specific component design, and in characterizing material and production processes. This also includes failure and defect analyses of parts and components, and consulting services on how to utilize ceramic components. In addition, the scope of services also includes creating production concepts and evaluating production processes while considering cost, quality assurance and energy efficiency. When introducing innovative technologies and realizing new products, Fraunhofer IKTS can support its partners until the transition to production is launched.