Acoustic methods

Special elastodynamic methods

Like ultrasonic methods, acoustic methods utilize elastodynamic interactions in an object to yield information about the condition of the object. This is frequently connected with acoustic signal radiation. Acoustic resonance testing is a wellknown and widely applied method for detection of cracks in parts such as ceramic utensils.

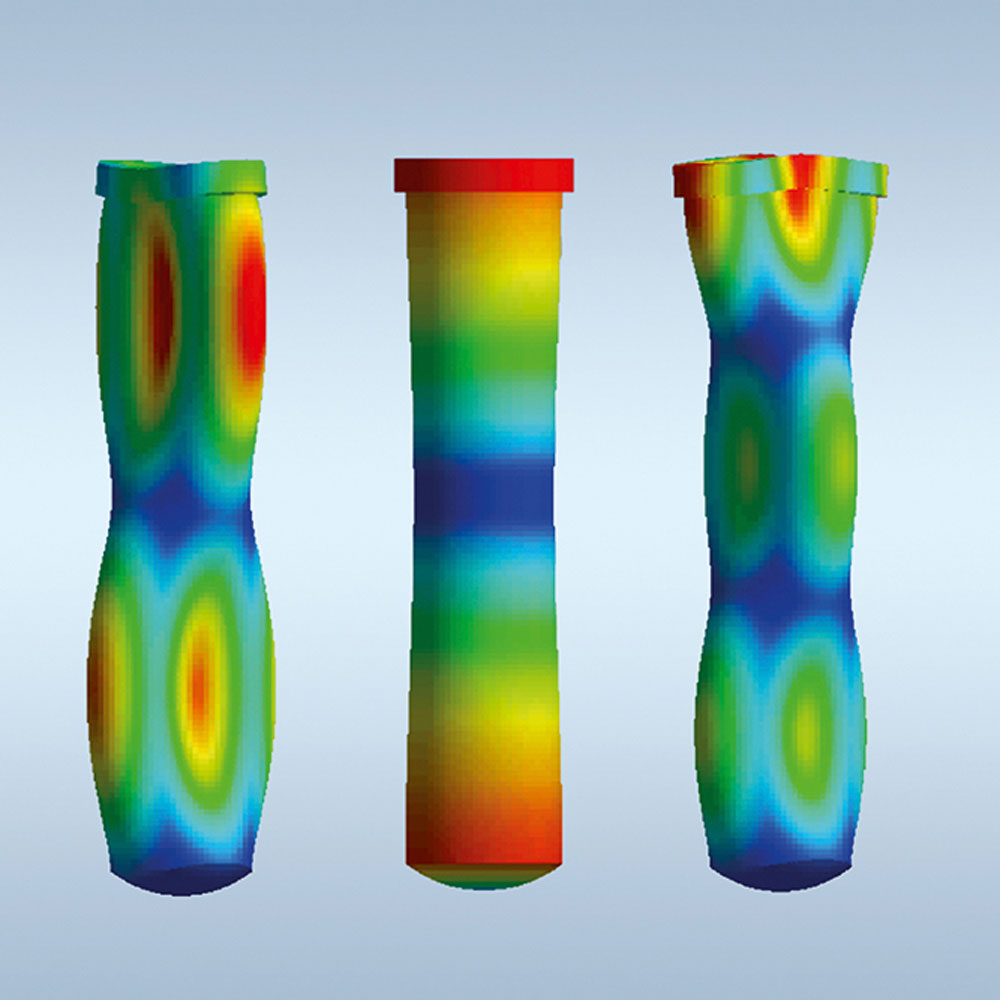

Scientists at IKTS supplement this initially purely empirical approach with experimental and theoretical model-based vibration analysis. Special elastodynamic methods cover a wide range of methods from the scalar acoustic waves until several 100 MHz linear and nonlinear bulk elastic waves. Thus, mechanical stresses can be determined from the relationship between the velocity of elastic wave propagation and mechanical stress. Focused very-high-frequency ultrasonics enables volume imaging with microscopic resolution (scanning acoustic microscopy, or “SAM” for short) to be performed on opaque objects.

If the application requires it, the methodology is modified to solve the given problems. One example of this is SAM tomography, which delivers a spatial representation similar to that provided by x-ray CT for tasks that are difficult for ultrasonics. Another recent development is imaging of surface microstructures via grazing elastic waves that are optically scanned.

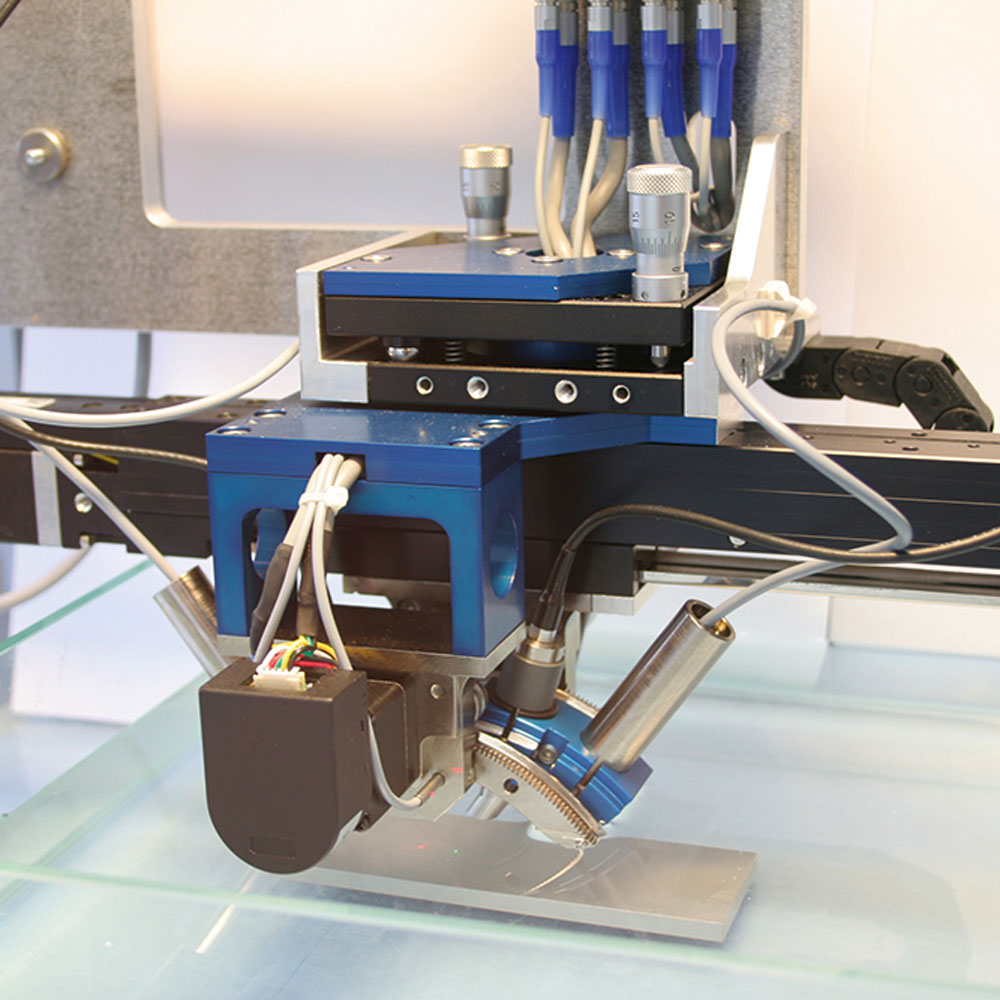

The available standard equipment does not always permit use of novel methods. When necessary, IKTS scientists can develop suitable equipment and make it available to customers.

Application fields

- Fast whole-part defect analysis

- Determination of surface gradients in mechanical properties and stress states

- Verification of layer adhesion, inhomogeneities, and cracks

Services offered

- Methods development and adaptation for individual test conditions

- Development and validation of adapted measurement systems

- Service provision and consulting

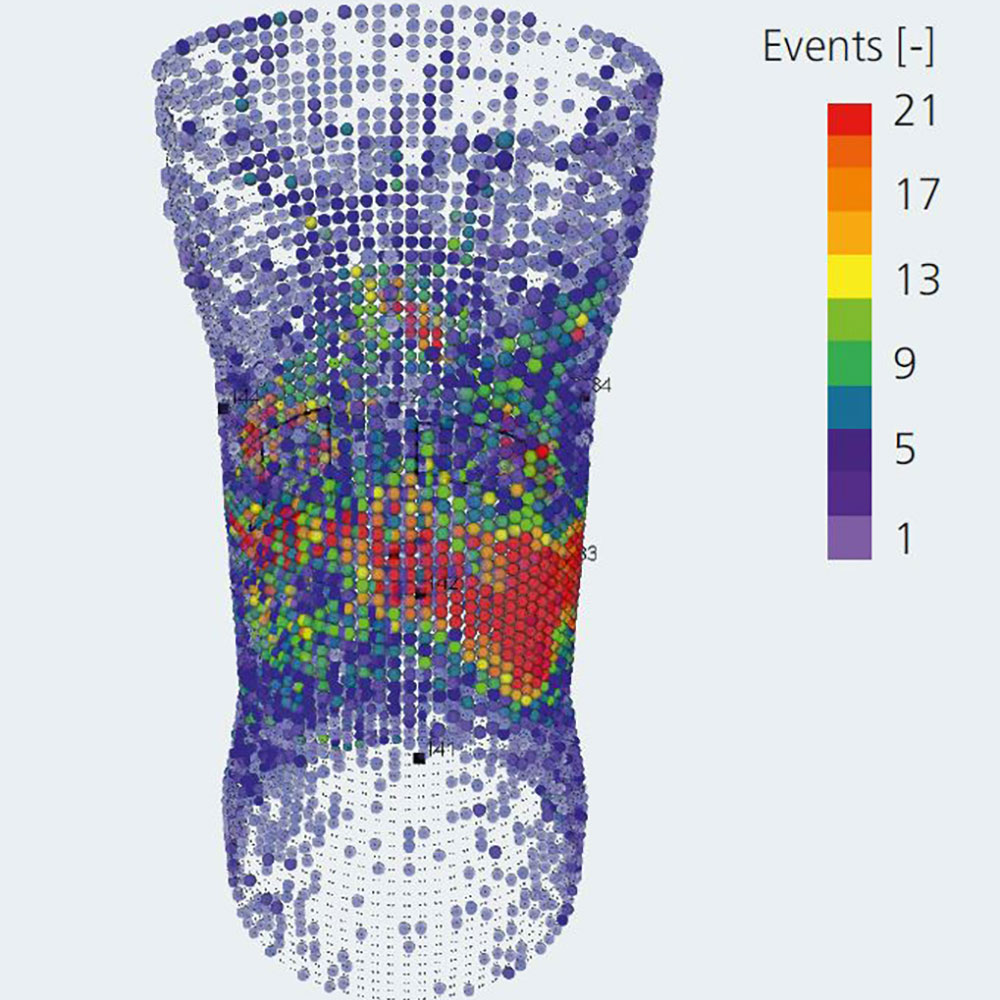

Acoustic emisson analysis

Fraunhofer IKTS provides acoustic emission analysis for damage detection of structural components during fatigue tests or under operational load by fast and reliable localization of sound emitting regions, e.g., due to crack growth. The position of the damage can be determined by the travel time of ultrasonic waves from damage to the sensors of the network. Furthermore, detailed signal processing allows the evaluation and the classification of the damage. The results from acoustic emission analysis offer detailed information which can be used for the focused application of conventional NDT methods and allows better load control during structural testing.

Acoustic emission testing is well suited for static and dynamic tests on fiber composite parts. These materials produce strong acoustic emissions when fiber breaks and delamination occur. In dynamic fatigue tests, the high level of noise from the surroundings and the acoustic properties of the composite materials might decrease the detectability and therefore lead to challenges. To face them and to ensure a wider applicability of acoustic emission, IKTS offers an acoustic measurement system with high measurement dynamics and sophisticated damage evaluation and localization algorithms. The system also supports the storage and the evaluation of complete waveforms. If used during fatigue testing, the distributions of acoustic emission parameters supply information about the structural state and allow to adjust the load conditions if needed.

Technical details

- High variability of acoustic emission measurement system due to modular structure of 4-channel sensor nodes

- Adaptation of in-house hardware and software to the given measurement task

Application fields

- Development of light-weight structures

- I ntegrity testing of light-weight structures under specific loading and environmental conditions

Services offered

- Accompanying measurements for static and dynamic structural fatigue tests (from coupons to large structures)

- Supply of measuring equipment

- Specific system and sensor design

- On-site installation of measurement systems

- Support in evaluation of recorded signals

- Employment of high-resolution NDT methods after location of defects and customer-specific development of acoustic measurement systems