Testing of Electronics and Optical Methods

Department

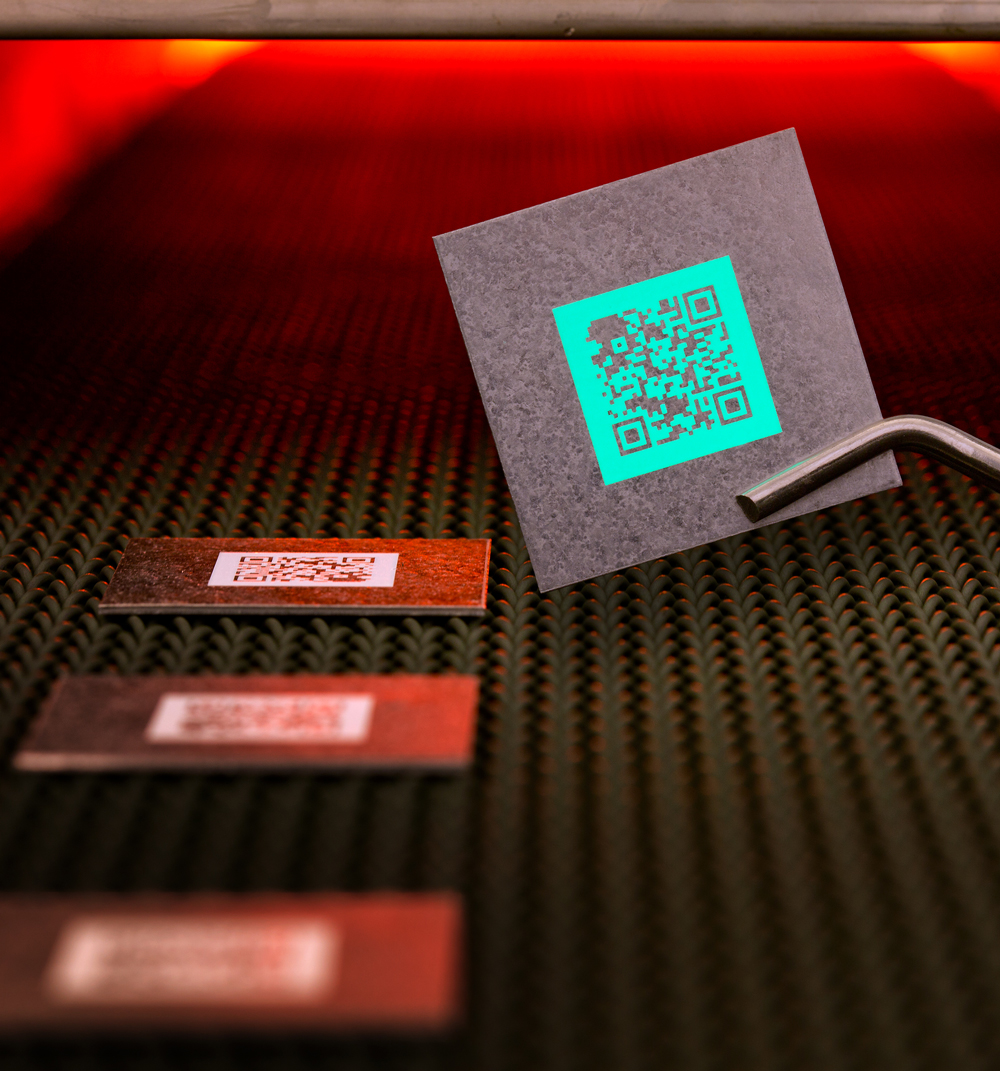

High-temperature component labeling under UV light.

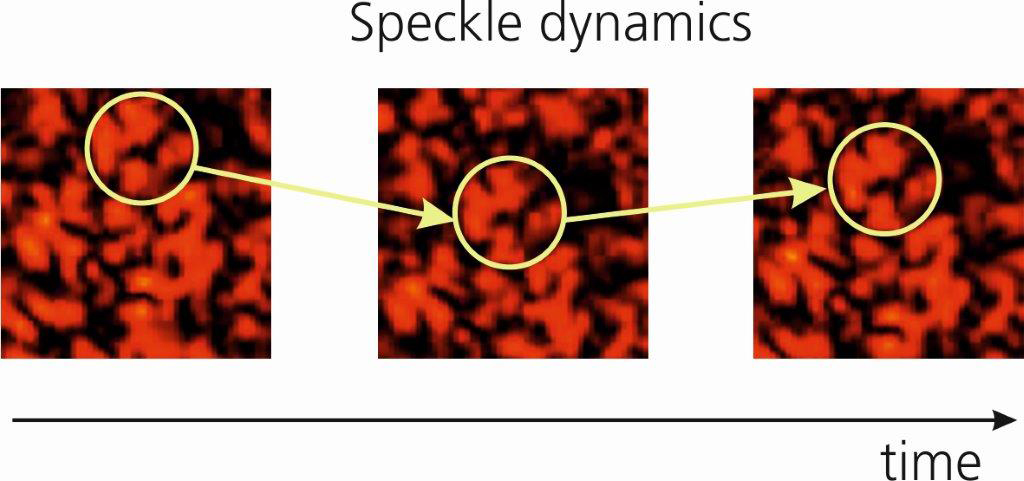

Change in speckle pattern with time for condition monitoring of processes and components.

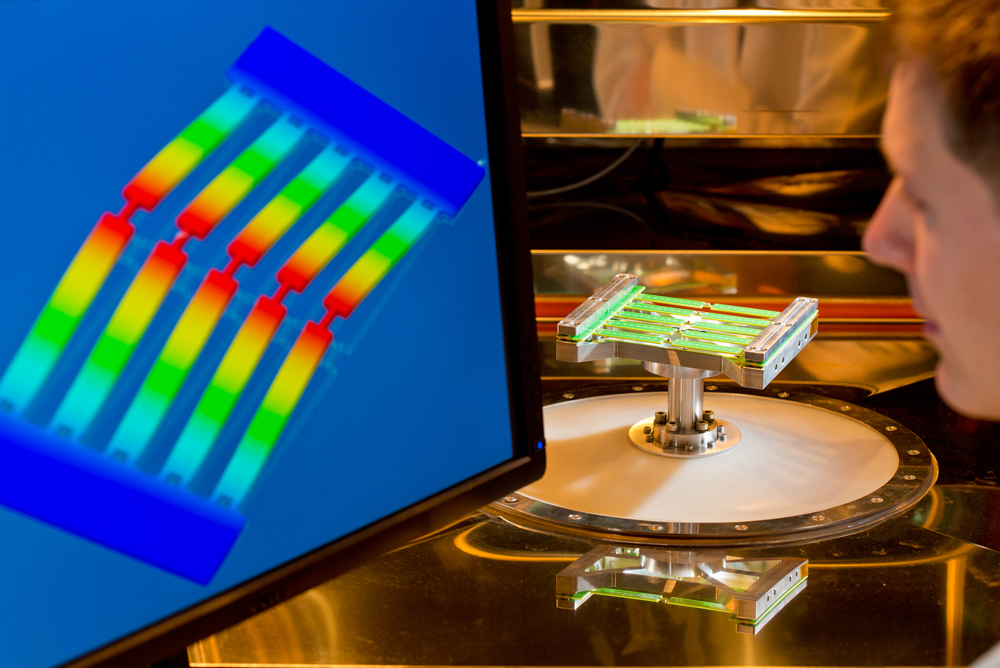

Simulation-assisted determination of failure behavior of electronic assemblies.

Components, structural assemblies, electronics, and microsystems as well as technical installations should function reliably at all times. The "Testing of Electronics and Optical Methods" department has the materials characterization methods and process knowledge needed to meet a multitude of testing demands. Non-destructive optical methods, structural mechanics simulations, and destructive test methods are used in component design, quality testing, and reliability evaluation.

Services offered

- Development of non-contact measurement and test methods for quality testing

- Robust optical markers for component labeling in high-temperature processes (up to 950 °C)

- Stress analysis of components, assemblies, and electronics

- Reliability analysis of electronics and microsystems

- Destructive materials testing for packaging materials

References/project examples

- Component labeling for extreme process conditions

- Optical solder materials testing, fatigue

- Robust electronics for the automotive industry

- LSP for monitoring stresses on large components with fatigue loading