About us

The Fraunhofer IKTS in Profile

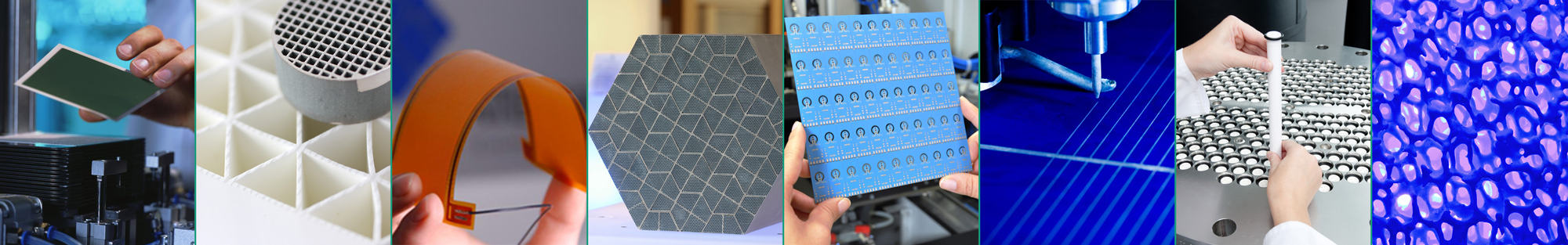

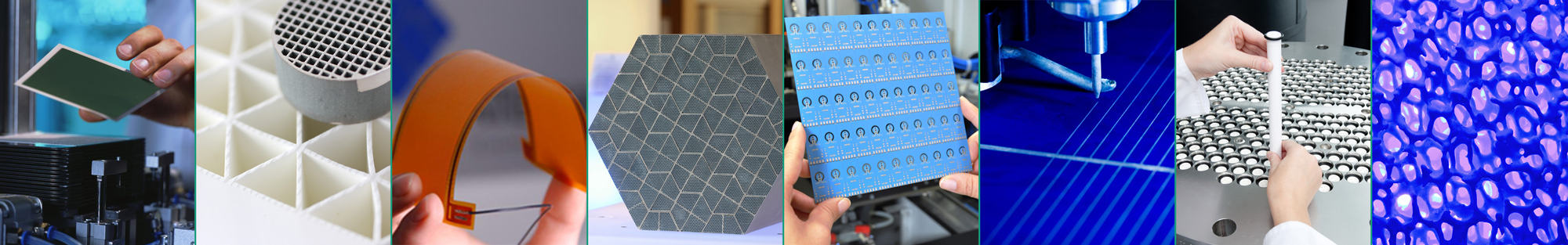

For more than 30 years, Fraunhofer IKTS has been demonstrating the potential of ceramic materials in a steadily growing range of applications. Our development work is derived from the needs of the nine market-oriented business divisions – supplemented by strategic preliminary research at the highest scientific level.

It is our goal to develop complete system solutions and services, but also to solve specific challenges within the processes of our partners from industry and science. Our expertise in characterizing materials, components and systems along their life cycle provides us with a unique data pool to carry out new developments more efficiently and faster.

With state-of-the-art equipment on more than 40,000 m² of floor space, competent staff and result-oriented research management, we offer a contact point for companies and research partners to tap the unique properties of ceramic materials for new and improved applications. Our special competences are:

Materials

We qualify ceramics, hardmetals and composites for specific application scenarios and master the necessary manufacturing processes at the highest level. We open up new fields of application through the targeted combination of structural and functional material properties. We can transfer developments from laboratory to pilot-plant scale and realize the prototypes and pilot series required for market entry, establish industrial manufacturing processes and implement quality processes.

Process engineering

We are one of the world‘s leading research institutes in the field of complex ceramic-based systems for energy-efficient separation processes, chemical mass transfer and materials recovery. Our approaches are based on the sustainable use of resources and closed material cycles. With state-of-the-art laboratory machinery and pilot plants, we can model, validate and optimize relevant parameters for these processes. With our excellent infrastructure, we are able to realize projects of the most diverse scope and scale.

Data-driven analytics and monitoring

Increasing the market acceptance of new materials requires high-performance analytics and quality control – from raw material evaluation to use and recycling. For the development of new materials and products, the clarification of complex failure mechanisms or the assurance of qualitative standards, we make use of new sensor concepts, robot-assisted measurements and the potential of cloud-based data acquisition and AI-supported data evaluation. In addition, we offer inspection systems for the condition monitoring of manufacturing facilities and thus ensure optimal product qualities, low inspection costs and reduced maintenance efforts.

System demonstration

For energy and process engineering systems, we are able to implement targeted system demonstrations based on market and customer requirements on one side and available technological options on the other. Material or technology issues are dealt with at the individual stages of the value chain, prototypes are evaluated on the basis of extensive validation and target/performance analysis of market readiness, as well as production and quality processes suitable for series production are developed. This qualifies us as a complete service provider for the entire process of technology development and the step-by-step transfer of knowledge into the customer’s series development.

Project management

Fraunhofer IKTS has proven competences in the planning and execution of research projects of various scopes – from short-term support to supernational large-scale projects. In the field of contract research with small and medium-sized companies, we provide flexible and timely support with customized services or development processes. In complex large-scale projects with various national and international consortium partners, we provide support from the application phase, to project coordination, communication of project outcomes and the development of exploitation strategies.

Cross-site quality management

Quality, traceability, transparency and sustainability are some of the most important instruments for IKTS when it comes to providing partners and clients with valid, reproducible and resource-friendly research outcomes. Therefore, Fraunhofer IKTS has a unified management system in accordance with DIN EN ISO 9001, as well as an environmental management system in accordance with DIN EN ISO 14001. Beyond this, the institute and its various divisions are certified according to other guidelines, among them EN ISO 13485:2016, and undergo various regular audits from the industry.

Creator of networks

We have an active role in numerous regional, national and international alliances and networks. By building and actively working within various networks, IKTS is able to identify different complementary competences at an early stage, and promote and integrate them for future product development. Thus, we jointly find solutions for the benefit of our partners.