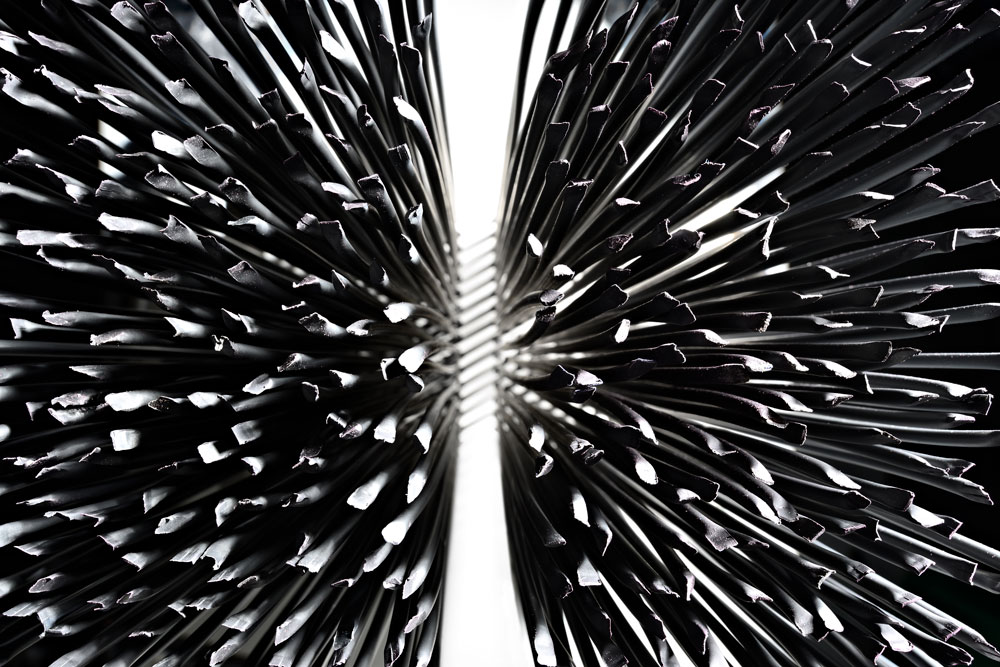

The working group "High-Temperaure Membranes and Storage Materials" deals with ceramic shaping of special mixed oxides, with coating of ceramic components and with the development of processes and systems based thereof. Suitable manufacturing technologies aimed for shaping and coating will be permanently improved. Ceramic components like membranes, storage materials and catalysts can be optimized regarding special properties corresponding to the application aimed, e.g. concerning geometry, layer thickness, porosity, cell density. A manufacturing of ceramic components based on special materials for pre-industrial pilot plants is offered.

Services offered

- Customized manufacturing of oxygen membranes, storage materials, catalysts in small-scale

- Development of technologies for ceramic shaping

- Optimization of component geometry concerning the process aimed

- Development of ceramic coatings (catalytic, protection and separation layers)

- Further improvement of special joining techniques (RAB, diffusion joining)

- Basic engineering of components and modules

- System analysis and process development

- Optimization of processes for high-temperature gas separation

- Integration of ceramic components for oxygen separation into systems