Largest membrane plant worldwide for high-purity oxygen production

Current research

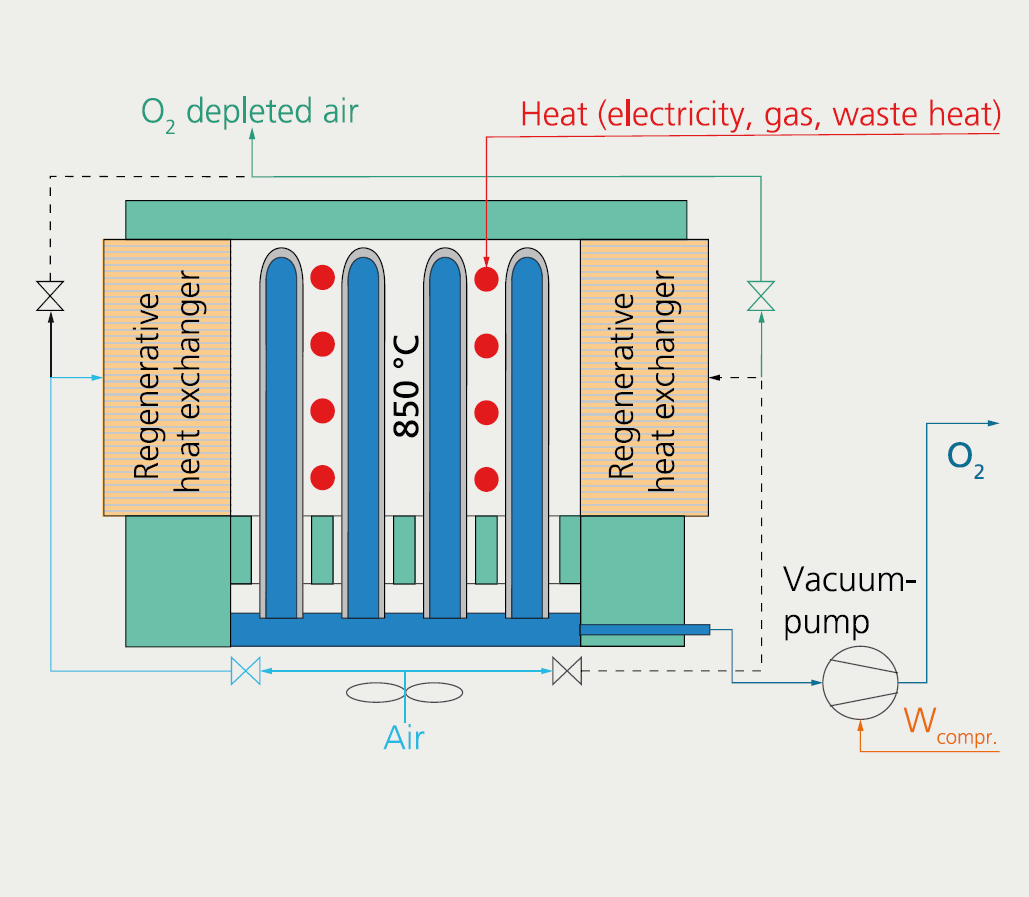

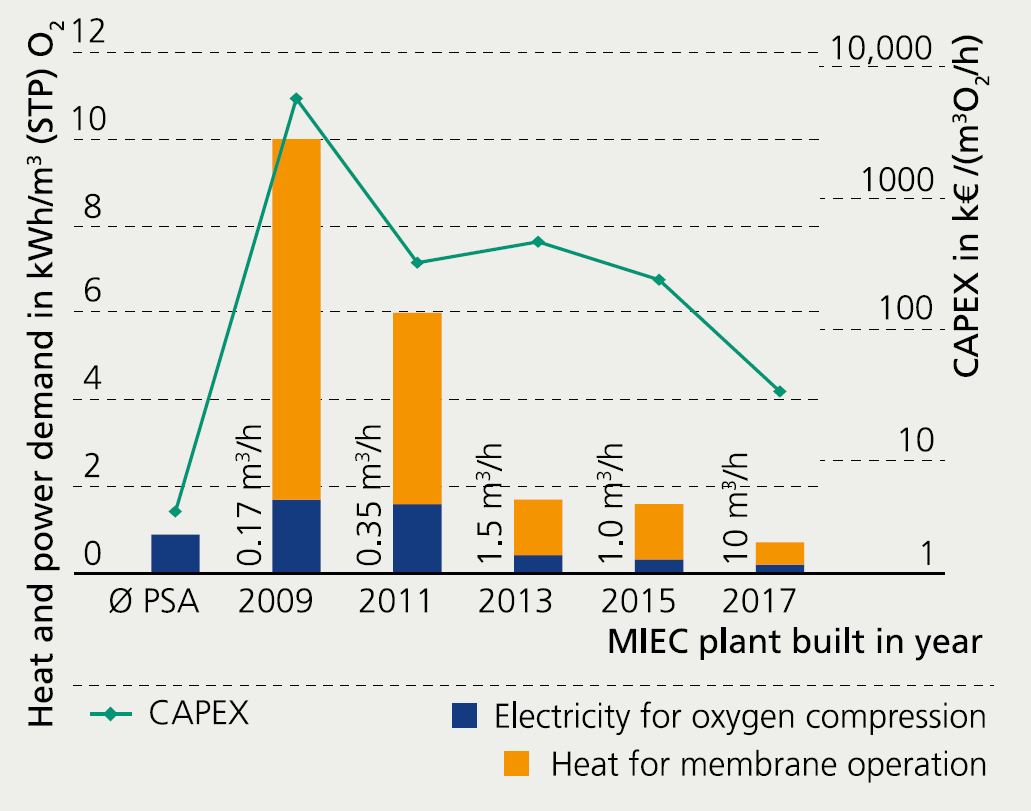

Oxygen is used in a wide variety of industrial applications, for example in the gasification of coal, in metallurgy (steel, copper, aluminum), and in the chemical industry. Additionally, combustion with pure O2 enables highly efficient CO2 capture and saves primary fuel. However, small heat treatment plants often cannot afford the supply of O2, as the unit price is significantly higher for smaller order quantities. On-site production, using the pressure swing adsorption (PSA) method, delivers only 93 vol % O2. This level of purity is frequently insufficient. Many industrial applications stand to benefit from the efficient and cost-effective on-site production of pure O2. Fraunhofer IKTS develops ceramic MIEC (mixed ionic electronic conductor) membranes – at high temperatures, these are permeable only for pure O2. Since 2009, several demonstration plants using these membranes have been realized. The diagram shows enhanced O2 throughput and continuously reduced energy demand and investment costs. Since 2015, goal of the BMBF-funded project MedPROmM is to create a pilot plant that could remain below the specific energy demand of a large cryogenic air separation plant requiring at least 0.5 kWh/m³ (STP) O2 (STP – standard pressure and temperature). In cooperation with industry partners, the patented concept for the plant (Figure 1) was implemented in a trial plant (Figure 2). During build-up, an enormous amount of modification and adaption of the CAD construction was required, since new technical solutions had to be implemented in many places. Due to thermal bridges at the plant housing, and because some regenerative heat exchangers recovered much less heat than anticipated, the real energy demand of 0.72 kWh/m3 (STP) O2 was higher than the target value of 0.46 kWh/m3 (STP) O2. However, the energy demand for O2 compression of 0.2 kWh/m3 (STP) O2 and O2 throughput of 9.8 m3 (STP) O2/h complied well with the target values. At 8000 hours of operation per year, a ten-year life-span, and electricity costs of 0.1 €/kWhel, the calculated O2 production costs amount to 0.43 €/m3 (STP). The alternative – supply with liquid O2 – would be almost twice as expensive, with additional costs of around 29,000 € per year.

Supported by