Advantages of decentralized oxygen production

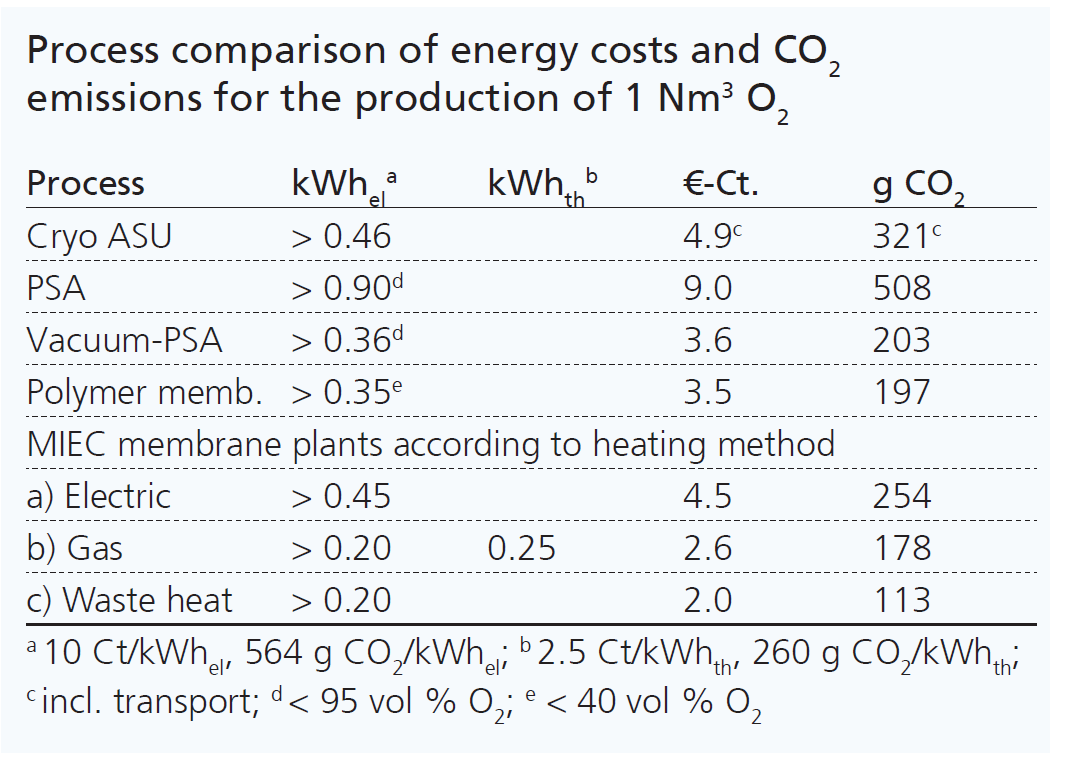

With a worldwide consumption of around 500 million tons per year, oxygen is one of the most frequently required industrial gases. On a large scale, oxygen is produced via cryogenic air separation (Cryo ASU) and usually transported to the customer. The price of oxygen therefore rises significantly for small quantities. Pressure swing adsorption (PSA) or its vacuum alternative (VPSA) is used for local production. However, the O2 purity is limited to around 93 vol % and the high power consumption strongly impairs the profitability of O2 use.

For cost-efficient on-site oxygen production, Fraunhofer IKTS develops oxygen-permeable ceramic membranes and corresponding oxygen generators. In addition to a high operating temperature, these so-called mixed ionic-electronic membranes (MIEC) only require different O2 partial pressures to generate pure oxygen. Therefore, the energy demand of the process is caused by the heat required to maintain the operating temperature and by the compression energy required for gas compression. The operators of these oxygen generators remain independent of gas suppliers.

Membrane manufacturing and process management

Fraunhofer IKTS is one of the leading research institutions in the field of separation techniques using ceramic materials. In the area of O2 separation from air using mixed ionic-electronic conducting ceramic membranes, IKTS is the only supplier of commercially available membrane modules and pilot plants with technically relevant capacities. The device concept and the patented process management are aimed at minimum operating costs and a long service-life.

The ceramic membranes are based on readily available raw materials. By using thin-walled membranes, the required material quantities have already been minimized and the oxygen output increased. The manufacturing process used is extrusion, which has a high potential for further cost reduction for large quantities. Any residual material resulting from the production process is completely recycled.

The membranes incorporated tolerate high heating and cooling rates or thermal stresses, so that membrane systems can be implemented with short start-up times. If required, stand-by operation and a variation of oxygen output of approx. 10 to 200 % compared to normal operation is possible.