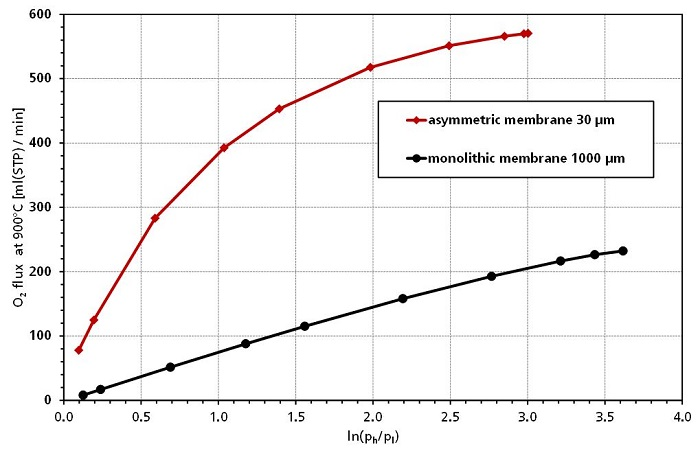

The oxygen permeation of MIEC membranes (Mixed Ionic Electronic Conductor) can be significantly increased by minimizing the membrane thickness. However, since a smaller wall thickness reduces the mechanical stability, monolithic MIEC membranes need at least a membrane thickness of approximately 0.2 mm. A substantial increase of oxygen permeation can be reached by asymmetric MIEC membranes consisting of a thin separation layer on a porous support. Due to the complex expansion behavior of MIEC materials the same material compositions are preferred for coating and support. Below a critical layer thickness, surface exchange of oxygen limits the O2 permeation. Therefore, optimized thickness of the dense separating layer is within the range of 10 - 50 microns. The leakage of the dense layer has to be very low in order to achieve a sufficiently high purity of oxygen produced.

For the development of asymmetric MIEC membranes two basic concepts were pursued. On the one hand preparation of porous supports was carried out using ceramic powders with different particle size distribution followed by multi-layer coating and intermediate sintering of the individual layers. In this way largely dense but not completely leak-free layers were achieved.

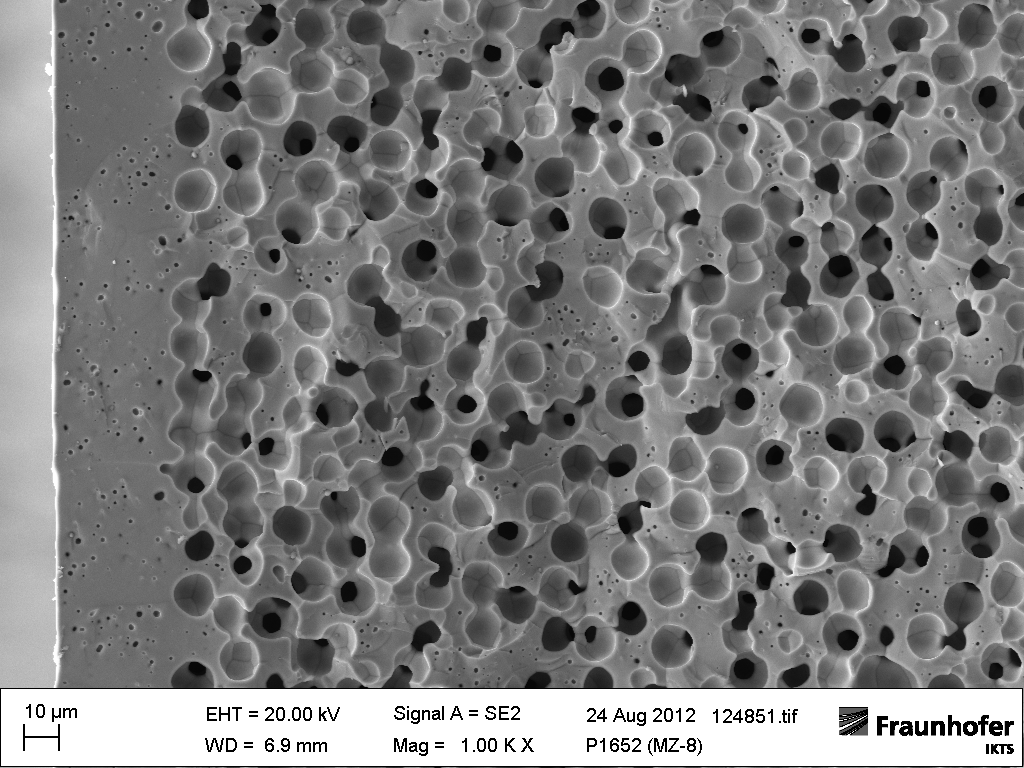

To simplify this complex manufacturing technology, ceramic powders were mixed with burnout materials, extruded to membrane tubes supports, coated in green state and sintered in a cofiring process. Decisive for success is primarily the adjustment of drying and sintering shrinkage of layer and support in order to avoid cracks in the separating layer. The manufacturing effort is drastically reduced for such BSCF membranes depicted in Figure 1 (BSCF - Ba0.5Sr0.5Co0.8Fe0.2O3-δ). Figure 2 shows the flow of oxygen through a BSCF asymmetric membrane with a layer thickness of 30 microns in comparison to a monolithic membrane with a thickness of 1 mm.

Services offered

- Development of asymmetric membranes made from different materials

- Development of asymmetric membranes of different geometries

- Deposition of catalytically active layers, protective layers