Oxygen is produced at large scale by cryogenic air separation consumes at least 0.36 kWhel. per m3(STP) O2 for very large plants highly optimized. Below 1000 m3(STP) O2/h, PSA plants (Pressure Swing Adsorption) und VPSA plants (Vacuum PSA) are used realizing not more than 95 vol.-% O2 in product gas. Small PSA plants with less than 100 m3(STP) O2/h) need at least 0.9 kWhel./Nm3(STP) O2. The energy costs dominate the O2 price for on-site O2 production which is in general much cheaper than a delivery of O2.

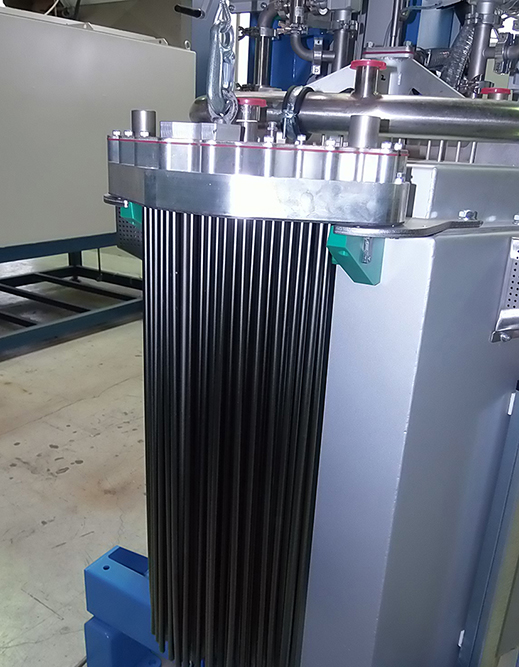

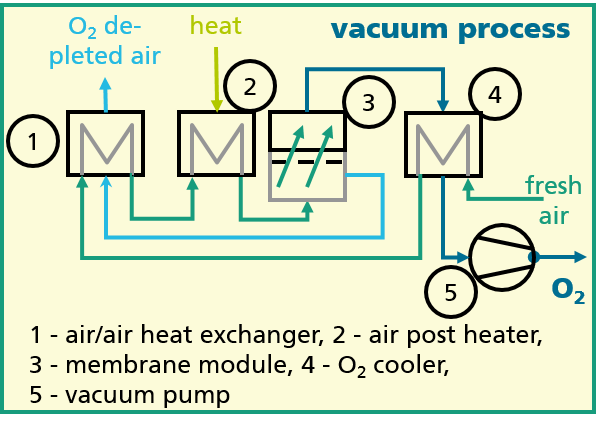

Production of pure O2 using MIEC membranes, also abbreviated as OTM (Oxygen Transport Membranes) or ITM (Ion Transport Membranes), requires a high temperature together with different O2 partial pressures. Accordingly, a MIEC membrane plant needs thermal energy for balancing the losses of air-air-heat exchanger. Besides, electrical energy or mechanical work is needed for compression of gases.

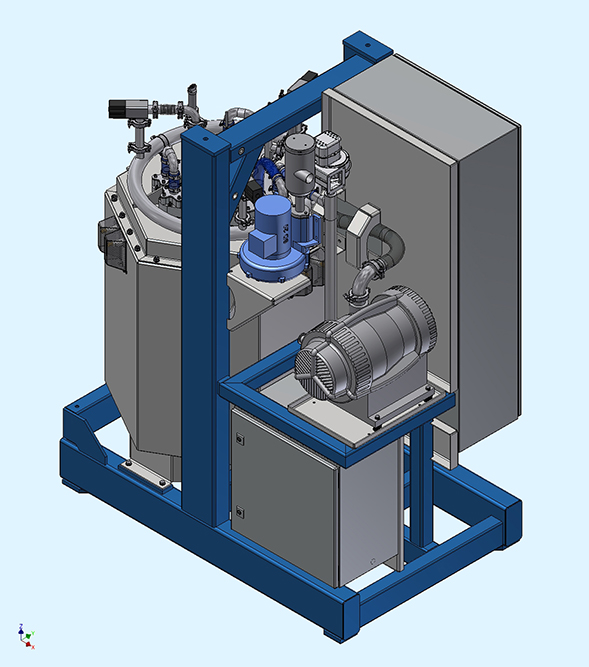

The overpressure process using compressed air which was often propagated is only competitive if more than 80 % of compression energy is recovered. Therefore, Fraunhofer IKTS develops a patented vacuum process characterized by a typical electricity demand of 0.2 kWhel. per m3(STP) O2. This process schematically shown in the figure below seems to be competitive already at a small scale. Thermal losses can be minimzed by special heat exchangers or can be equilibrated by the use of waste heat of industrial processes. All together, operational costs are significantly lower compared to conventional processes mentioned above. Therefore, costs for production of O2 on-site are further reduced.