Water is key for new closed resource loops

The global demand for water is increasing due to ever more intensive water use. At the same time, the usable water supply is becoming progressively smaller. To ensure that water does not slow down key industries, the energy transition and food security, several research groups at the Fraunhofer Institute for Ceramic Technologies and Systems IKTS are working on projects that at-tempt to solve current problems in the water, agriculture, and energy sectors in a holistic approach. One goal here is to use wastewater as a resource. This in-cludes, for example, new recycling methods for municipal and mining wastewater, which can provide important raw materials for sustainable agricul-ture as well as for the growing demand for hydrogen.

“Water is the key to the economic ecosystem of the future,” says Dr. Burkhardt Faßauer, who heads the Department of Circular Technologies and Water at Fraunhofer IKTS. “And with our technologies, we can finally couple the water, energy and food sectors in a highly efficient way.” Properly treated, water can become a source for raw materials, fertilizer, and energy.

Example 1: Phosphorus recycling in the wastewater treatment plant

A new technology developed by Fraunhofer IKTS enables phosphorus to be recovered from municipal wastewater - a resource that is often underestimated. After wastewater treatment, sewage sludge remains in the treatment plant, which, in addition to valuable phosphorus, also contains heavy metals such as lead, cadmium and nickel, some of which are harmful to health and environment. The closed-loop technologists therefore feed the sewage sludge into a fluidized bed incineration reactor and convert the heavy metals into gases by adding additives at temperatures between 800 and 1000 degrees Celsius. These are separated directly in the incineration process with the aid of special high-temperature-resistant ceramic filter elements. What remains is an ash consisting of up to 15 percent phosphate. Without the heavy metals, this mineral can be more easily extracted from the ash and applied to fields as a yield-enhancing fertilizer. In further process steps, it would also be possible to upgrade some of the separated heavy metals for industrial use. Fraunhofer engineers in collaboration with the Technical University of Dresden and LTC – Lufttechnik Crimmitschau GmbH are currently retrofitting this separation technology in a pilot plant in Pirna in order to evaluate the above-mentioned method in large-scale trials.

Example 2: Municipal wastewater as an energy provider

Sewage sludge digestion allows sewage gas to be extracted from wastewater, 60 percent of which consists of methane. The remaining parts are composed of carbon dioxide and other compounds. With carbon-based filters from Fraunhofer IKTS, the CO2 can now be filtered out of the sewage gas. On the one hand, this increases the efficiency of the sewage gas-fired combined heat and power plants (CHP), which generate electricity and heat. On the other hand, it will also be possible to set up complex loops based on this concept in the future: The captured CO2 and green hydrogen could be used in Fischer-Tropsch synthesis to produce valuable products such as synthetic fuels. Alternatively, the captured CO2 could be pumped into greenhouses to increase crop yields. Space-saving cultivation techniques such as vertical farming, located in the immediate vicinity of wastewater treatment plants, are conceivable. This would result in completely new business models for municipal sewage treatment plants.

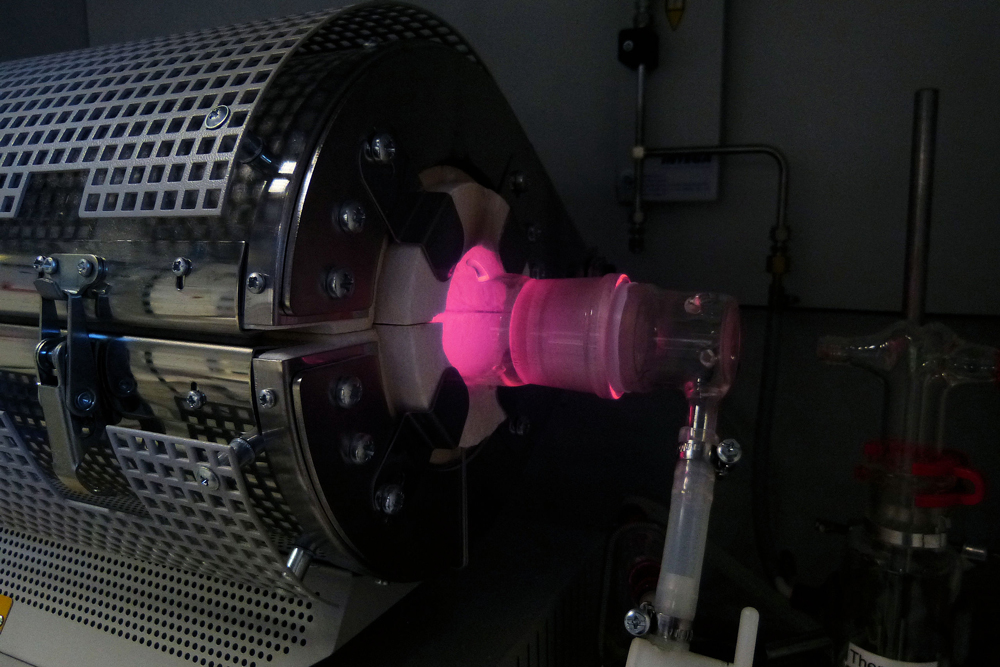

Example 3: Green hydrogen from mining waters

Wastewater from mining operations contaminated with sulfates is a serious problem: it upsets natural ecosystems and acidifies entire water supplies. But even these mining legacies can be transformed from a burden into a resource thanks to modern electrochemical processes. The IKTS systems developed for this purpose feed mining wastewater directly into a cascade of successive electrochemical flow cells. Inside these cells are membranes and electrodes. When current is applied, the charged sulfates continuously accumulate in one direction. It is then easy to combine the sulfates with nitrogen compounds to produce high-quality ammonium sulfate fertilizer. Hydrogen is also produced as a by-product. This is regarded as a particularly eco-friendly energy carrier and a sought-after feedstock for many industrial processes. IKTS is currently testing these purification and refinement processes for mining wastewater in pilot plants such as “TERZINN” and “Rainitza”. The results are promising. Therefore, the researchers want to transfer these methods to a larger scale in the future.