For quality assurance, non-destructive testing (NDT) quickly provides reliable information about the quality of a product or the condition of a system. Defects and weak points can be detected early and damage can be avoided.

As an NDT specialist, Fraunhofer IKTS in Dresden-Klotzsche develops application-specific solutions for ultrasonic testing – from simple manual test systems and laboratory scanners to complex phased-array systems for automated ultrasonic testing. The PCUS® pro series is a modular and powerful testing electronics system that allows adaptation to a wide variety of testing tasks with little development effort and thus by meeting all of the relevant parts of the ultrasonic standards ISO 22232-1 and ISO 18563-1.

The PCUS® pro array frontends enable evaluations with much higher image resolutions than conventional sector scans. For this purpose, phased-array data can be collected with Full Matrix Caputre (FMC) and processed with Total Focussing Method (TFM), a signal processing algorithm.

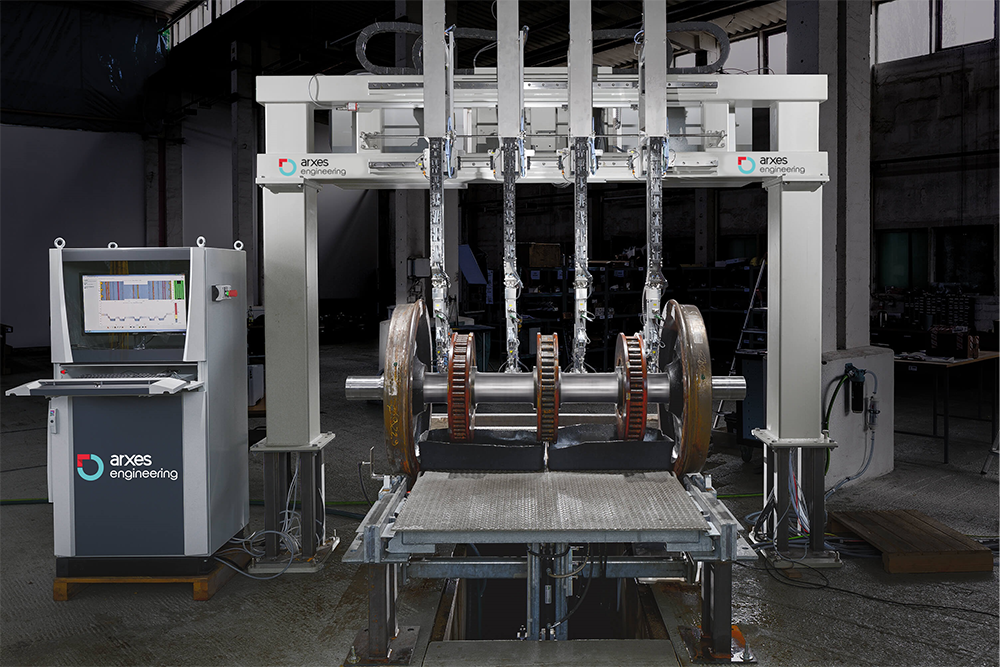

The development work of the "Electronics for Test Systems" group includes analog and digital systems for signal processing in the high-speed range. The numerous fields of application for IKTS ultrasonic electronics include hollow shaft and solid shaft test systems that test highly stressed components in rail transport and, increasingly, robot-based test systems for complex components. These are used in automotive engineering, aerospace, shipbuilding and the energy sector.