Automated ultrasonic testing of thin metal sheets using PCUS® pro HF

Current research

Challenges of ultrasonic testing

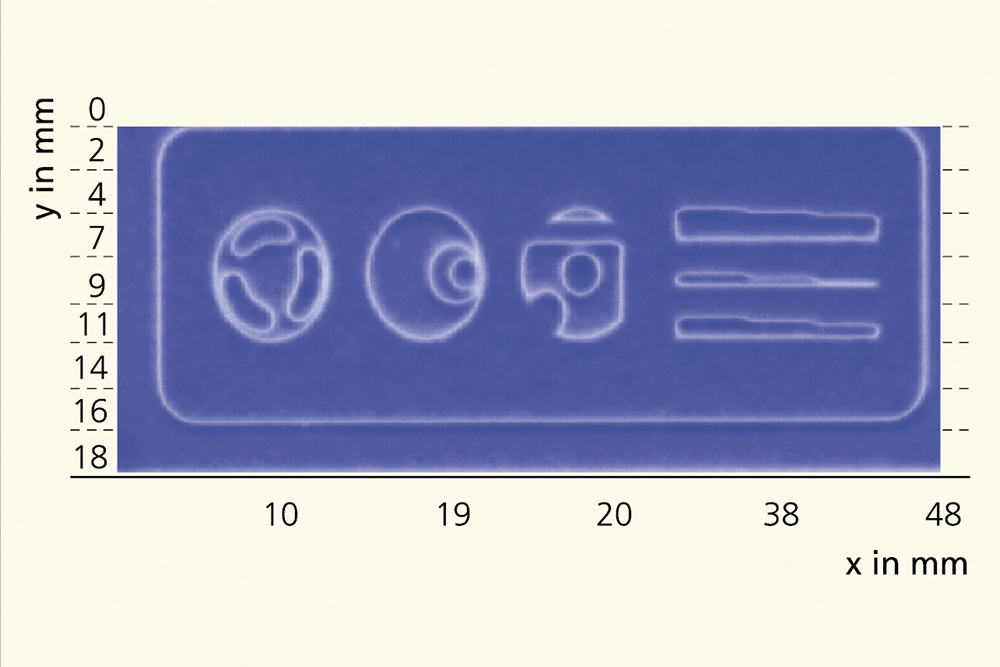

Frontend devices of the “PCUS® pro” family are made for automated non-destructive ultrasonic testing. A usable frequency range of 500 kHz to 30 MHz enables conventional ultrasonic testing applications, such as the testing of welds and semi-finished products, or recurrent testing in the transportation sector. However, new materials and factory methods translate into new challenges for non-destructive testing. The growing demand for lightweight structures in the automotive industry has led to the use of very thin metal sheets with complex shapes, joined by small-sized laser or spot welding. Such small and mostly hard-to-access structures cannot be tested by conventional ultrasound techniques because they require higher measurement resolutions as well as higher signal frequencies. Until now, such test tasks have therefore been solved with destructive test methods or measurements with high-frequency ultrasound microscopes. As ultrasound microscopes are not inline-capable and cost-intensive, this technique is often applied to random samples only.

High signal frequencies for new test tasks

The frontend device “PCUS® pro HF”, developed at IKTS, bridges the gap between classic ultrasonic testing and high-frequency ultrasound microscopy. The inline-capable frontend is suitable for signal frequencies in the range of 5 to 150 MHz. With its compact measurements of 170 x 120 x 30 mm3, it can be mounted in direct vicinity to the probe, e.g. directly onto mechanical scanners. Passive cooling combined with a low power consumption of only 7 watts allows for a wide range of industrial applications. It is connected to the host PC using a high-speed USB 3.0 data transfer bandwidth with the possibility for implementing fiber optics. The design offers very low-noise analog electronics, a widely adjustable transmitter and the implementation of as many features used in “classic” ultrasound test devices as possible.

Simple integration into existing plants

The “PCUS® pro HF” frontend device is compatible with all other members of the “PCUS® pro” family and can be controlled by a software development kit (SDK). This SDK enables the integration into customer-specific application software. For easy incorporation of the hardware into custom testing and production plants, the frontend device includes interfaces for incremental encoders, external triggers and digital inputs and outputs.