The Process Systems Engineering group is focused on the development of processes and reactors for different catalytic, non-catalytic and electrochemical applications. The close connection of experimental studies with process modeling and automation allows for covering the whole development chain from process concept to technical realization in a pilot plant. The evaluation of the examined process is conducted with regards to technical as well as to economic aspects.

Core competencies

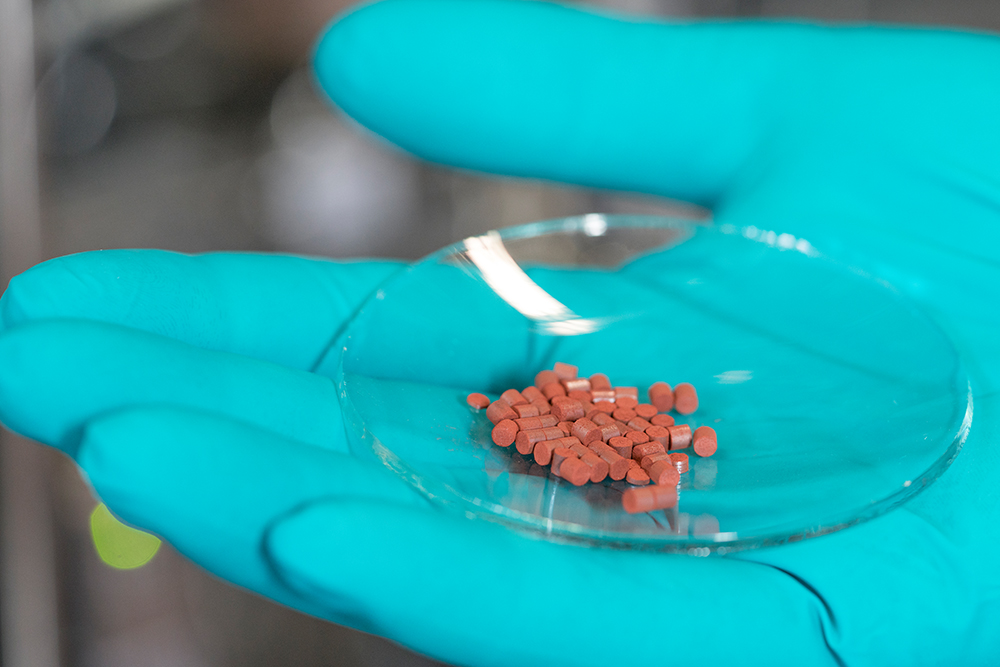

- Catalyst screening, characterization and development

- Reactor development for catalytic and non-catalytic processes

- Model-based process development

- Techno-economic assessment of process concepts

- Control development and process visualization

- System demonstration and automation

- Feasibility studies and scientific project assistance