In connection with the necessary reduction of industrial CO2 emissions, power-to-X processes are of crucial importance, as they allow the use of renewable energy for the production of various chemical products. This is achieved by coupling an electrolysis for hydrogen supply with a product synthesis step. In this way, synthetic fuels, e.g. for the aviation sector, as well as important basic chemical products can be produced. Carbon-based raw materials for the chemical industry, which can be further processed e.g. into plastic products and cosmetics, as well as compounds such as ammonia, which is decisive for the production of fertilizers, are also an option. Due to the conversion of the entire energy system and the associated increase in demand, renewable electricity will remain a limited resource in the foreseeable future. Consequently, the processes used need to be highly efficient. At the same time, costs for the transition to a renewable energy system should be minimized. Therefore, it is important to identify the most efficient and economic options among the various possible power-to-X processes prior to their technical implementation.

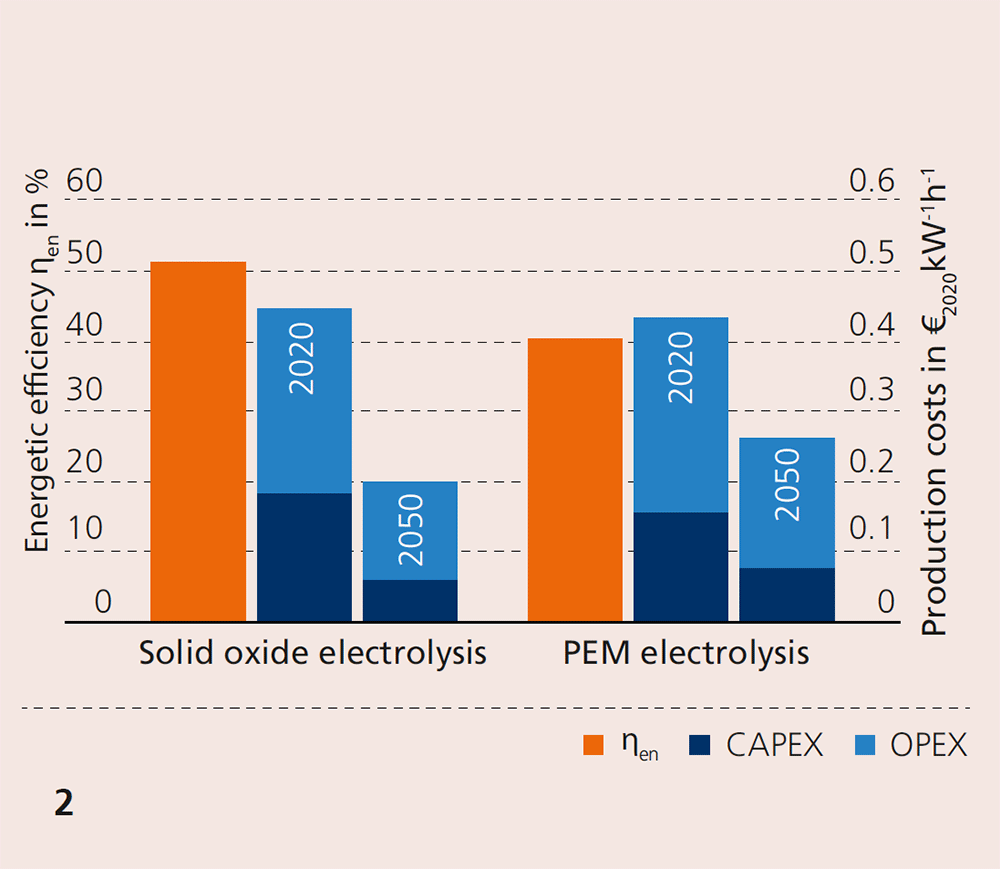

Fraunhofer IKTS employs various tools for energetic and economic evaluation to achieve this. A technical evaluation of different process routes is carried out with the help of process simulation and experimental data from demonstration plants. In addition to technical maturity and feasibility, special attention is paid to efficiency. Using an economic model developed at IKTS, the production cost of renewable products can be calculated for different processes and scenarios. One of the studies evaluated the production of synthetic crude oil from CO2 and H2O by coupling electrolysis and Fischer-Tropsch synthesis. The established polymer electrolyte membrane (PEM) electrolysis was compared with the ceramic-based solid oxide electrolysis developed at Fraunhofer IKTS. The different levels of technological readiness of the two processes make this comparison particularly interesting; it allows to evaluate their potential based on the expected future development of the technologies. The results show that the process based on solid oxide electrolysis has a higher potential due to the ability to utilize waste heat generated by the synthesis step or provided externally, therefore yielding a higher energetic efficiency than the process based on PEM electrolysis. Since this process is not yet as technologically mature, current manufacturing costs do not reflect this advantage. However, when the production of solid oxide electrolyzers is established on an industrial scale in the future, significant economic advantages are to be expected for this application.

An advantage of the tools developed for the conducted analysis is that they can also be applied to evaluate other technical processes.