Development and evaluation of process engineering for sustainable energy and raw material systems

The transformation in the chemical as well as in other industrial sectors in order to limit CO2 emissions causes profound changes to existing process chains. The development of concepts for the substitution of fossil resources with renewable resources is an area of expertise of the Process Systems Engineering group.

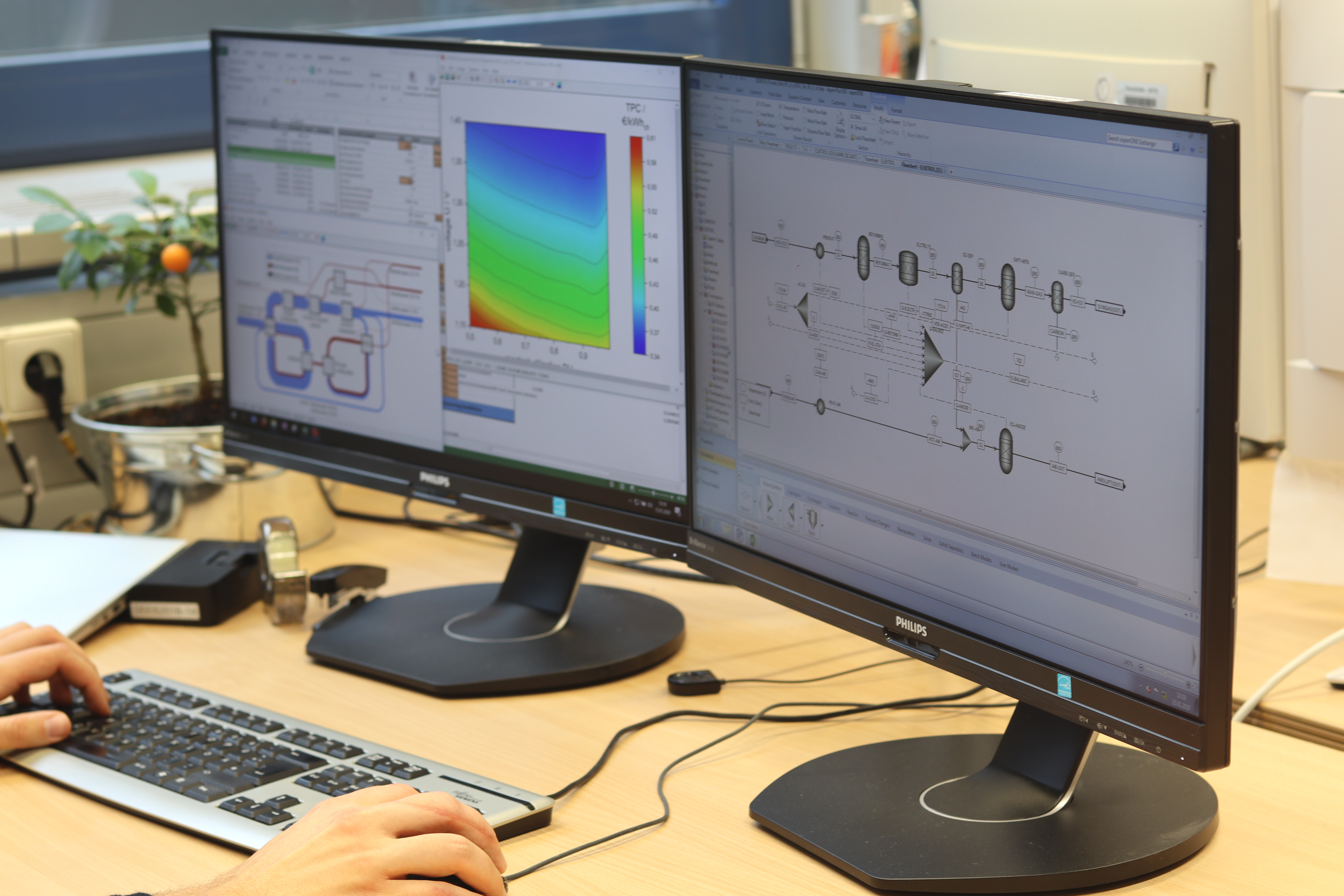

Services include modeling of state-of-the-art processes in order to assess the potential for optimization. In order to do so, a broad library of process steps is available, which can be updated with empirical or thermodynamic models.

Furthermore, novel process concepts can be designed and simulated. Based on the obtained data, extensive comparisons to the state of the art considering technological as well as economic aspects can be conducted, allowing for an evaluation of the competitiveness of the considered approach. Promising process concepts can be realized in pilot-scale plants.

Services offered

- Design of innovative process concepts

- Modeling of process steps as well as of entire processes

- Technical analysis of process concepts

- Implementation in lab or pilot scale

- Economic and ecologic feasibility analysis

- Feasibility studies

References

- Development and evaluation of the emission reduction potential of a hydrogen-based direct reduction process for steel production

- Development and demonstration of a process for the production of Fischer-Tropsch waxes from biogas

- Techno-economical evaluation of power-to-X processes for the production of hydrogen, hydrocarbons and ammonia