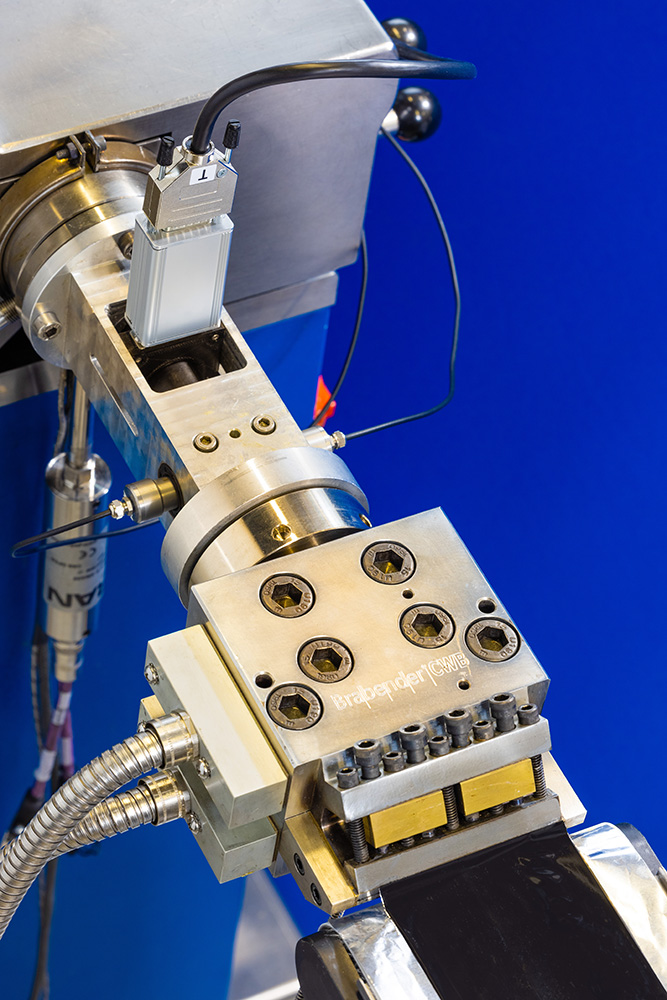

The "Process Development and Process Monitoring" working group transfers new electrode materials from the laboratory to pilot production. The team's expertise in handling mixing, characterization, coating and drying technologies is fully available for this purpose. In order to be able to map the complete production chain for Li-ion batteries and their components, Fraunhofer IKTS operates the Battery Technology Application Center at its Freiberg site, which is equipped with a drying room. Research and development also focuses on new manufacturing processes such as cold and hot plastic flat tape extrusion for conventional or polymer solid-state cells.

In order to minimize production errors in the manufacture of lithium-ion battery cells and reduce the high reject rates, it is essential to detect errors early on in the production process. This prevents defective components from being further processed and unnecessary follow-up costs from being incurred. In addition, this also contributes to resource-saving battery production. In collaboration with the various working groups at IKTS, new testing methods are being tested in battery production and used for production-integrated testing systems. Non-destructive methods such as ultrasound, eddy current, laser speckle photometry, radiography and thermography are combined and adapted to the individual production steps. The integration of AI-controlled algorithms also facilitates the analysis of large data sets and enables the identification of error patterns and the optimization of production processes.

Services offered

Process development

- Electrical, electrochemical and material-analytical characterization of materials and components for Li- and Na-solid-state batteries and Li-ion batteries

- Model-based electrode development and optimization according to customer specifications

- Conducting material and coating tests for electrode tapes

- Development, testing and optimization of integrated manufacturing concepts for electrode and cell production

- Up-scaling of laboratory processes and technology transfer in the dry room

- Feasibility studies and consulting in the area of process scaling

Process monitoring

- Development and combination of non-destructive testing methods for inline monitoring of electrode manufacturing processes such as mixing, drying, calendering and slitting

- Testing of commercial and prototype inline testing systems

- AI-based data evaluation

- Detection and classification of production errors