Ceramics in exhaust gas purification

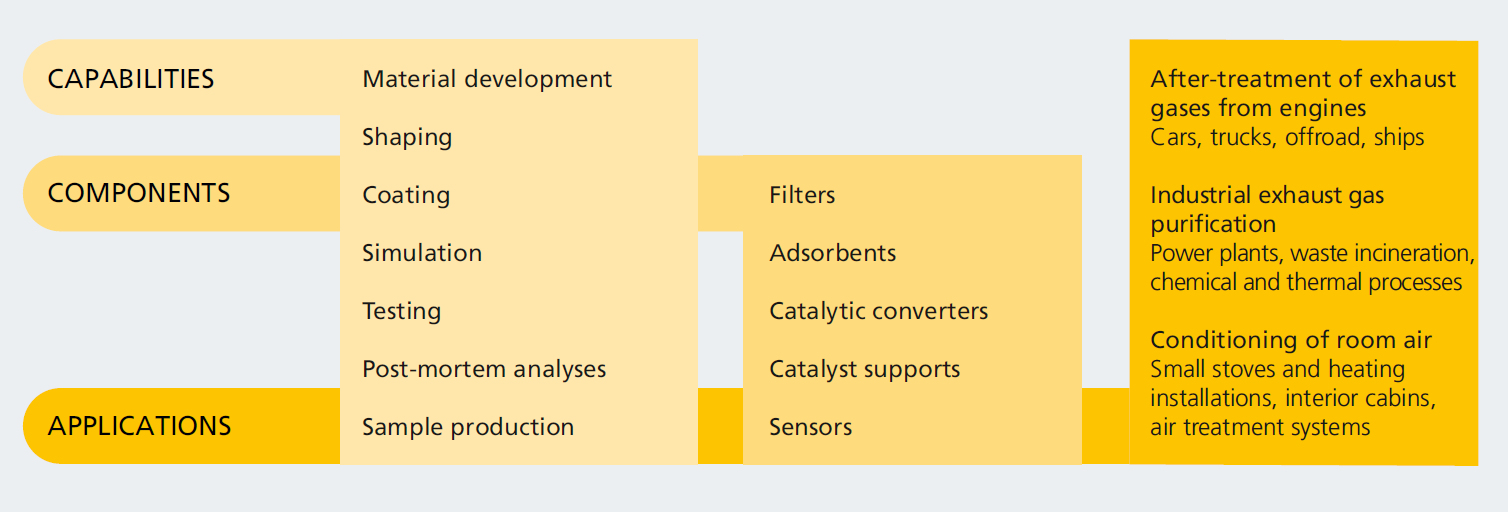

Exhaust gases from various technical environments pollute our ambient air and can result in environmental and health damage. With regard to purifying exhaust gases and complying with emission and immission limit values, the available methods differ vastly from each other depending on type and origin of the pollution. In many of these methods of purification, ceramic filters, adsorbents, catalytic converters and catalyst supports enable efficient and cost-efficient results, in particular when it comes to high temperatures, chemical corrosion and longevity.

Ceramic catalyst supports and diesel particulate filters have become indispensable, in particular with regard to the purification of exhaust gases from internal combustion engines, such as gasoline or diesel engines. Every year approx. 20 million ceramic catalyst supports and particulate filters are integrated in Western European cars alone. Beyond this, ceramic components play an important role for the purification of exhaust gases from large-scale industrial processes, such as from power plants, waste incineration plants and chemical and thermal process engineering plants. Ceramic filters and catalytic converters are even used in many household applications.

Thanks to its many years of development in this area, Fraunhofer IKTS helps to optimize materials and manufacturing methods and opens up new applications. The institute also provides sophisticated analysis, modeling and simulation technologies, some of them newly developed, to support the optimization of materials, components and processes. The examination of ceramic components following field tests is also part of the portfolio. Furthermore, IKTS has extensive know-how in the development of ceramic gas sensors and complex sensor systems for use in exhaust gas purification.

Cooperation models

Innovation and development are the cornerstones of a promising corporate future. In order to create a competitive edge, Fraunhofer offers tailored options for cooperation, so that small and medium-sized companies can work together in the best possible way. This also allows to utilize development skills at short notice and as needed.