Treatment of exhaust gases from engines

Exhaust gases from engines of passenger cars, trucks, offroad vehicles, stationary plants or vessels are among the main emission sources of air pollutants. Compliance with emission standards for carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NO) and particulate matter (PM, PN) is therefore a major aspect in the development of internal combustion engines. While air pollution has been reduced in recent years to respond to stricter emission standards and thanks to improved exhaust gas treatment technologies, metropolitan areas still see immission limit values for nitrogen oxide and fine particulate matter exceeded on a frequent basis.

Particle filtration

Fine particulate matter from engine combustion is carcinogenic and thus especially dangerous for humans and the environment. Particulate filters allow to reduce fine particulate matter from engine exhaust gas safely and effectively. The method is already widely used in diesel particulate filters and has also been introduced in modern direct-injection gasoline engines in the form of gasoline particulate filters (GPF). The filters used for these applications need to meet the following requirements:

- Strong filtration effect for the efficient separation of extremely fine particles from the exhaust gas

- Low back pressure in the unloaded state and while the filter is being loaded with particles in operation

- High thermal resistance to withstand the high temperatures and temperature gradients found during regeneration

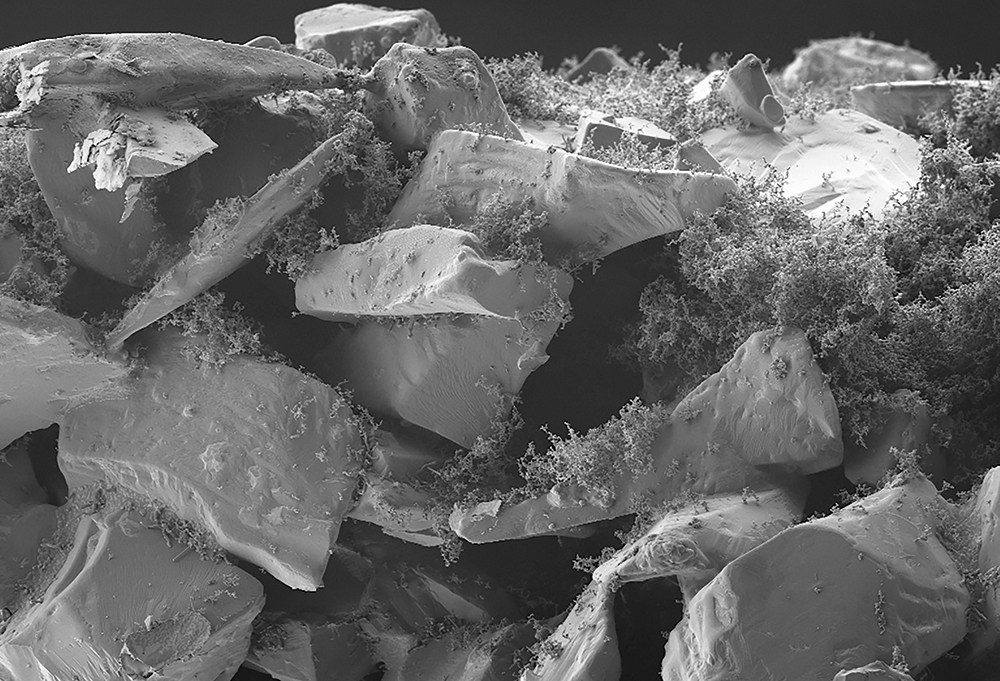

Ceramic wall-flow filters for soot particle filtration have already reached a high standard of development in recent years. At the same time, emission standards are becoming more stringent and more energy-efficient vehicles are required, meaning that further development is necessary in the future, focusing in particular on reducing back pressure and improving the separation performance of particulate filters, as well as combining particulate filtration with catalysis.

Fraunhofer IKTS has been developing and analyzing particulate filters for 20 years. Research is focused on material development for substrates from various materials, such as SiC (RSiC, LPS-SiC and oxidically bound SiC) or cordierite, and on the design of the particulate filters and their extensive characterization. For this purpose IKTS covers the full process chain, from the selection of materials to mass preparation, shaping (e.g. extrusion) and heat treatment. Various characterization and test methods are used for the individual technological steps. This includes e.g. viscosity, tolerance and shrinkage analyses, as well as checks of the thermal degradation of ceramic additives using TG/DTG.

Another large field of activity of Fraunhofer IKTS is the characterization of particulate filters in new or post-mortem condition with regard to back pressure, separation performance, ash deposit, strength values, thermophysical properties, chemical composition and microscopic as well as macroscopic properties.

Catalysis

Catalytic converters are used in engine-related applications to reduce carbon monoxide, hydrocarbon and nitrogen oxide emissions, as these pollutants are particularly hazardous for the health of humans and for the environment on account of their irritant and toxic effects. The testing and development of catalytic converters for exhaust gas treatment is one of the main fields of activity at Fraunhofer IKTS. This includes the analysis of properties and operating behavior of conventional catalytic converters as well as the implementation of novel catalytic converter solutions. Among such solutions are diesel oxidation and DeNOx catalytic converters and functionalized particulate filters.

Various catalytic supports, such as highly porous honeycomb and filter segments or open-cell foam ceramics, are at the center of this work. Different catalytic structures are compared with each other, with the aim of assessing properties relevant for application, such as reactivity and back pressure, which are affected by different types of flow behavior. Optimized and innovative coating technologies are another focus of our work.

IKTS has two syngas test stands with modern analytical equipment at its disposal, allowing to examine and optimize catalytic converters and catalytically coated particulate filters. The test stands also enable us to determine light-off temperatures and conversion rates for oxidation and SCR catalytic converters in stationary or dynamic test cycles. Furthermore, transient switching between rich and lean gas compositions allows to determine the conversion behavior of three-way and NOx catalytic converters. These analyses are dependent on the temperature (up to 900 °C with heating rates of up to 30 K/s), the exhaust gas composition (CO, CO2, NOx, O2, HC, H2O, NH3, SOx) and the volume flow (up to 200 l/min). To achieve representative and meaningful results, we use specially produced 3test specimen geometries (catalyst segments or core samples) and adapt the sample volume to suit the flow conditions relevant for the application.

In addition to these reactivity analyses, special methods for characterizing material properties are also available. A better understanding of deactivation mechanisms is possible through the analysis of age-related changes of the catalyst composition, wash coat structure, specific surface and the mechanical and thermomechanical properties.