Sustainable energy storage for renewable energies

The balcony power plant is booming. But where to put the electricity generated when nothing is being consumed in the household? This is where rechargeable stationary energy storage systems come into play. Dual-ion batteries (DIB) do not contain any harmful metals and are made of materials that are available in Germany. This novel technology promises lower costs, safety, independence as well as sustainability.

The dual-ion battery (DIB) is a fairly recent development based on graphite cathodes. The use of graphite means that the battery requires no critical materials, such as cobalt or nickel. The advantages of the DIB approach are a long lifetime, high energy density, low costs and unproblematic use of raw materials. Previous studies focused on the material level and the production of laboratory cells. Pouch cells and other industry-relevant cell formats have so far remained largely unexamined. The same applies to scaling up to pilot scale.

Transfer to industry as a major goal

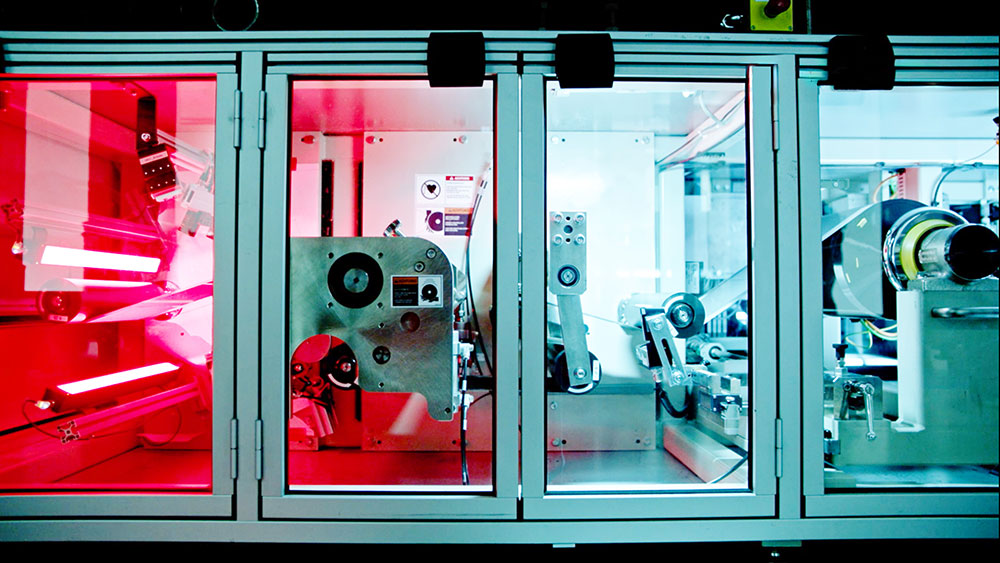

The TransDIB project (“Development and transfer of cost-efficient, sustainable and safe dual-ion batteries for stationary energy storage solutions”) now aims to transfer this battery cell technology to industry. To this end, the project partners intend to produce prototypes in a Li-ion battery (LIB) pilot plant. This will then be used as the basis for planning industrial cell production for DIBs, so that graphite electrodes can ultimately be manufactured on a large scale in a roll-to-roll process. To accomplish this, partners from industry (VARTA Microbattery GmbH, SGL Carbon GmbH, E-LYTE Innovations GmbH, Sixonia Tech GmbH) and research (Dresden University of Technology, Fraunhofer Institute for Ceramic Technologies and Systems IKTS, Westphalian Wilhelms University Münster) are working hand in hand in the project.

Qualification of new materials

To achieve the goals, fundamental aspects of DIB technology must also be further developed. This primarily concerns materials developments for highly concentrated electrolyte formulations and new graphitic electrode materials. The aim is to increase the capacity of cathodes and anodes, develop water-based electrode slurries or increase the energy densities of the cells.

In this area, Fraunhofer IKTS contributes its expertise and implements multiscale characterization from atomic level to cell size. In addition, aging and degradation processes of the used materials are investigated in in-situ approaches. And by modifying graphite materials, the capacity, energy, reversibility and lifetime of electrodes and active materials are to be increased.

Advantages of DIB

In a DIB, the electrolyte acts as the active material because both anions and cations are stored and released simultaneously in the anode and cathode, respectively. Since the path taken by the ions is only half as long as in conventional Li-ion batteries, the charging and discharging process is correspondingly faster. The use of graphite also has other advantages. For example, the cathodes can be produced from aqueous formulations. This is not only sustainable, but also cheaper than standard Li-ion batteries. In addition, the batteries are very safe because no oxygen needs to be used in the electrodes and the graphite electrodes remain stable even at high charge rates. Last but not least, DIB cells can be manufactured entirely from materials available in Germany. This promotes German technology leadership and leads to independence from critical raw material sources.

Promising applications

Stationary energy storage systems are mainly used for intermediate storage of green electricity from renewable energy sources, such as solar and wind. Compared to current storage technologies (e.g. pumped storage power plants), stationary batteries are characterized by a smaller installation space. This reduces investment costs. Moreover, because they are modular in design, these storage systems can be easily scaled, making them just as suitable for commercial applications as for household grid use.

TransDIB project

The project “Development and transfer of cost-efficient, sustainable and safe dual-ion batteries for stationary energy storage solutions – TransDIB“ runs from February 2023 to January 2026 and is funded by the German Federal Ministry of Education and Research with 2.3 million euros within the guideline “Battery materials for future electromobile, stationary and other industry-relevant applications (Battery 2020 Transfer)“.

Project consortium

- VARTA Microbattery GmbH (project coordinator)

- SGL Carbon GmbH

- E-LYTE Innovations GmbH

- Sixonia Tech GmbH

- Dresden University of Technology (TUD)

- Fraunhofer Institute for Ceramic Technologies and Systems IKTS

- Westphalian Wilhelms University Münster