Cell-level characterization

Electrochemical characterization

Electrochemical materials characterization forms the basis for achieving a comprehensive understanding of the electrochemical processes taking place inside a lithium-ion battery. Fraunhofer IKTS has an broad repertoire of electrochemical methods and supplementary measurement procedures for determining the capacity, cycling stability, cell voltage, and impedance of electrode materials for batteries.

One main focus of development work at Fraunhofer IKTS is on methods for complementary measurements during operation. Electrochemical investigations are coupled with spectroscopic, gravimetric, or temperature measurement methods in order to gain detailed information about the processes taking place during charging and discharging of the storage materials.

It is precisely these complementary investigations that allow to establish correlations between the electrochemical behavior of the materials and the material properties of the individual battery components. With a detailed understanding of kinetic and thermodynamic processes as a function of charge state, cycle number, and temperature, it is possible to identify concrete optimization routes. This in turn opens numerous possibilities for targeted materials development and design optimization.

Related Links

Cell performance and service life

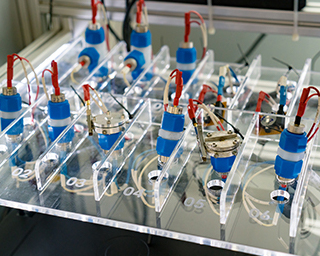

Developed materials and technologies can be suitably evaluated via characterization of the cell performance (performance data) and the service life (cycle life and calendar life) of laboratory battery cells. The information gained can also be applied towards evaluation or comparison of performance and applicability of various cell types in connection with post-mortem analyses or for determination of simulation parameters. Fraunhofer IKTS conducts targeted performance tests to investigate the charging and discharging behavior under fluctuating temperatures and to optimize the internal cell resistance.

Lifetime testing is performed with a wide range of defined load cycles in conjunction with aging tests at different temperatures. This yields information on cycling stability as well as long-term stability of the batteries.

Modern battery test stands at Fraunhofer IKTS enable testing and characterization of complete cells up to a capacity of 40 Ah by means of current/voltage measurements and impedance spectroscopy as well as application-specific load cycles.

Related Links

Cell benchmarking and post-mortem analysis of commercial lithium batteries

Post-mortem-analysis of battery cells

In the so-called post-mortem analysis, exhausted or defective battery cells are opened carefully in a protective atmosphere and investigated with respect to aging effects, degradation, and failure mechanisms.

This allows the effects of developed materials and technologies or specific operating conditions on aging to be researched. Samples can also be taken in a protective atmosphere for subsequent analytical structural characterization. By means of these samples, the individual electrodes can also be assembled to form button cells and special electrochemical characterization can be performed, e.g., for determination of the lithium loss in the storage material.

Another main application field for post-mortem analysis is investigation of failure mechanisms in defective cells. Manufacturing defects and causes of battery failure can be analyzed on behalf of customers. Information about interactions between cell design, system integration, and operating mode can be derived and thermal battery management optimized.

Related Links

Cell benchmarking and post-mortem analysis of commercial lithium batteries

Simulation

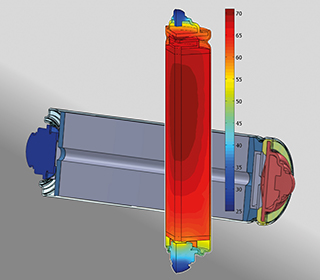

Because of the strong interactions between thermal and electrochemical processes, fine-tuned thermal management is the key to the safe and long-lasting operation of lithium-ion batteries. One important aspect of this is the avoidance of local thermal loading inside the battery.

For this, state-of-the-art simulation tools are used for detailed analysis of the effects of structural elements (coil, housing, contact structures) and material-specific parameters on the thermal behavior inside a lithium-ion cell during operation. Thus, they provide a unique in-situ insight into the battery cell conditions, which would hardly be able to be observed directly in real operation.

Possible applications for these simulation models are battery design optimization as well as, e.g., virtual battery labs, specification of cell operating limits in high-performance battery applications, and calibration of rough, real time-capable lithium-ion battery models.