Digital services in analytics and non-destructive testing at Fraunhofer IKTS

Current research

Challenge

Digital transformation will bring enormous changes to the scientific work of Fraunhofer IKTS. Not only will the latest methods of machine learning and pattern matching have to be integrated into existing analytics processes and procedures. Digital tools and bona fide business models need to be developed as well. At IKTS, research data are by nature very heterogeneous: Material, process and environmental data need to be collected and processed according to the FAIR (findable, accessible, inter- operable, reusable) principle. Only data collected in this way, i.e. in a structured and systematic manner, can be evaluated, linked or used as the basis for generating synthetic data and models, allowing to reach new levels of value creation. At the same time, scientists cannot readily outsource the tasks of data analysis and AI projects, since this requires a common language and understanding between specialists and data scientists.

Implementation

Living up to these new challenges requires novel, cross-disciplinary teams consisting of materials scientists, natural scientists, engineers, IT specialists and data scientists. Such teams are currently being established by IKTS across several sites, e.g. in Cottbus (research group Cognitive Material Diagnostics, KogMatD), Forchheim and Arnstadt (Battery Innovation and Technology Center BITC). The fact that digital methods can work independently of site or location is a crucial advantage, allowing for agility and the efficient use of resources. For instance, computing resources and storage space can be made available from any of the institute’s sites if suitable virtualization and cloud strategies exist to enable all IKTS business divisions and sites to use a combination of analytics and modeling, simulation, automation, as well as qualitative and statistic data evaluation.

Another factor is equally important: Material researchers and data experts at IKTS need to come to a shared understanding of digital value creation. They need to know and learn to comprehend technical terms, challenges and methods of the respective subdisciplines, be that materials science, engineering or data science. Moreover, digital methods also mean completely new ways of working for the IKTS research groups. This includes concepts, such as design thinking, rapid prototyping and agile teamwork.

Early AI elements are already part of the work routines of IKTS. Specially trained models are used to process large datasets from acoustic condition monitoring, while X-ray and microscopy data are improved and assessed with the help of image analysis algorithms. Sensor data from camera images and ultrasonic devices are merged. Automated literature analyses or the evaluation of past projects, the interlinking of data from simulations and experiments all lead to increased efficiency and improved quality. Even today, the equipment of IKTS makes use of highly specialized algorithms to optimize CAD files before they are processed.

The site of Forchheim is set to become a trailblazer for context microscopy and spectroscopy, in this context developing further, for IKTS as a whole, analytical measurement modalities, some of them absolutely unique, and preparing multimodal workflows – from data collection to statistical evaluation to visualization.

Examples of business models

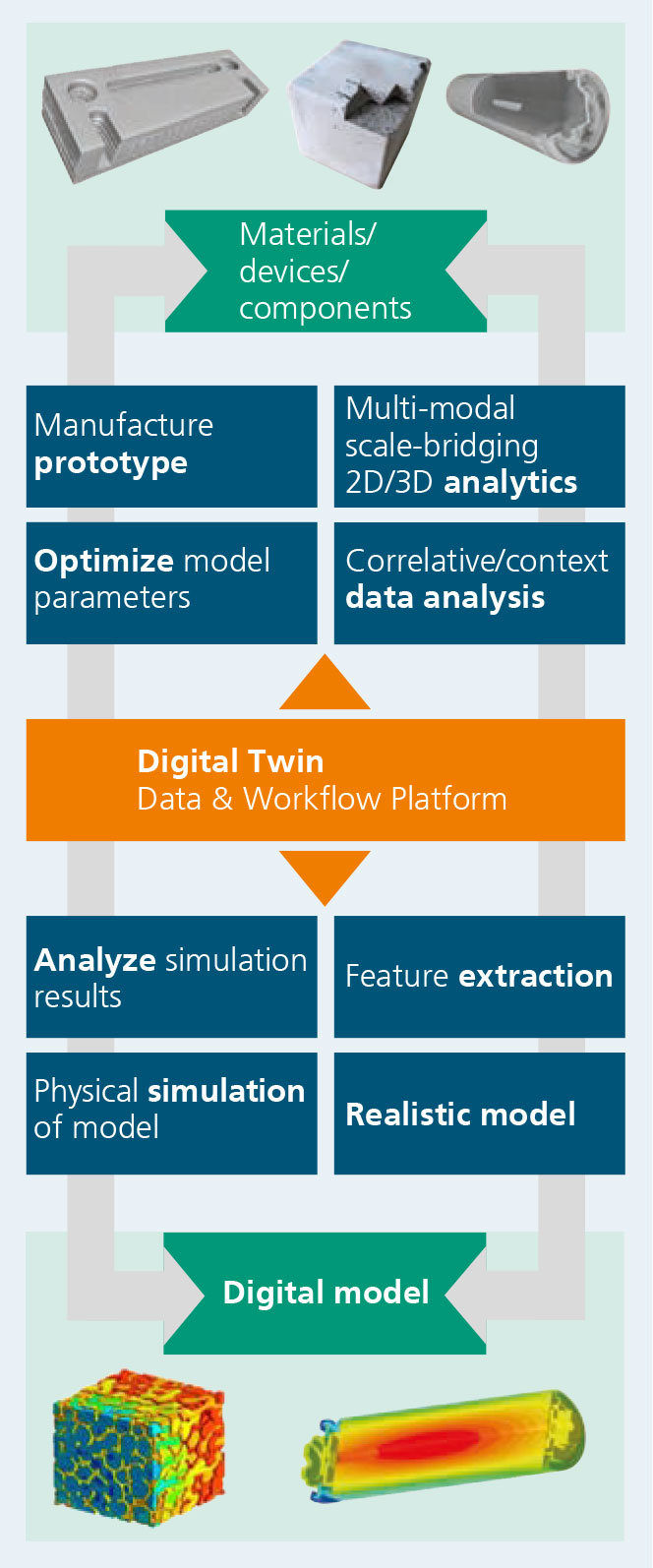

At the core of the digital offering of IKTS with regard to correlative microscopy are workflows that link individual databases with associated work steps. These workflows are run centrally on a high-performance computing infrastructure (HPC). On one side, the cluster interlinks the multitude of heterogeneous, multimodal and cross-scale data from individual microscopic processes. On the other side, Fraunhofer IKTS employees of all sites, but also external customers and project partners, gain access to this workflow engine. An intuitive user interface allows to store data in a structured way, work on quantitative data analyses or visualization, or merge data that were collected with multiple modes to create models, simulations or “digital twins”.

The workflow engine ensures that the data management adheres to FAIR principles and enables storing meta- and process data or sample IDs. The system also allows to integrate and feed external data processing tools, such as software for data compression, the segmentation of image data, or finite-element solvers.

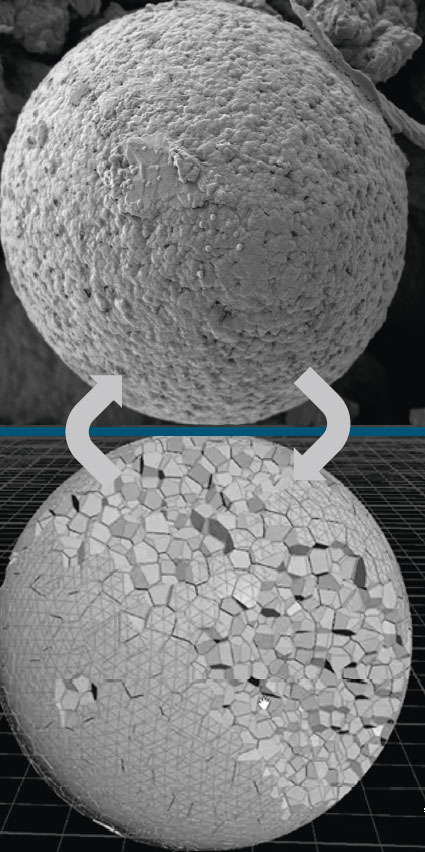

For instance, microscopy data – numerous synthetic datasets based on photorealistic, three-dimensional renderings – have served as training data for machine learning (ML) algorithms to further develop battery materials. The figure on the right shows an electron microscopic image of a particle (of 20 μm diameter) from a nickel-cobalt-manganese alloy as used in cathode films.

Data accrued or existing with industrial clients constitute another domain where IKTS intends to create value in the future. These often very diverse material, process, testing and environmental data are generated across the complete value chain. Collecting, interlinking and evaluating them is a challenge that IKTS meets with more than just technology. By having their representative as the “product owner” participate in the agile process, clients of IKTS can optimize the development’s direct usefulness even during the project period. This works well in various project formats, virtually as well as with physical presence. For IKTS, this is a big step toward setting up and introducing agile processes and mastering the fast and continuous delivery of features.

Industrial clients in particular will be ever more closely involved in the project work of IKTS in the future. The institute will ramp up its integration into the big national and international data science platforms, such as “Material Digital”, and make increasing use of the open-source methods of software development that are typically found in the industry.

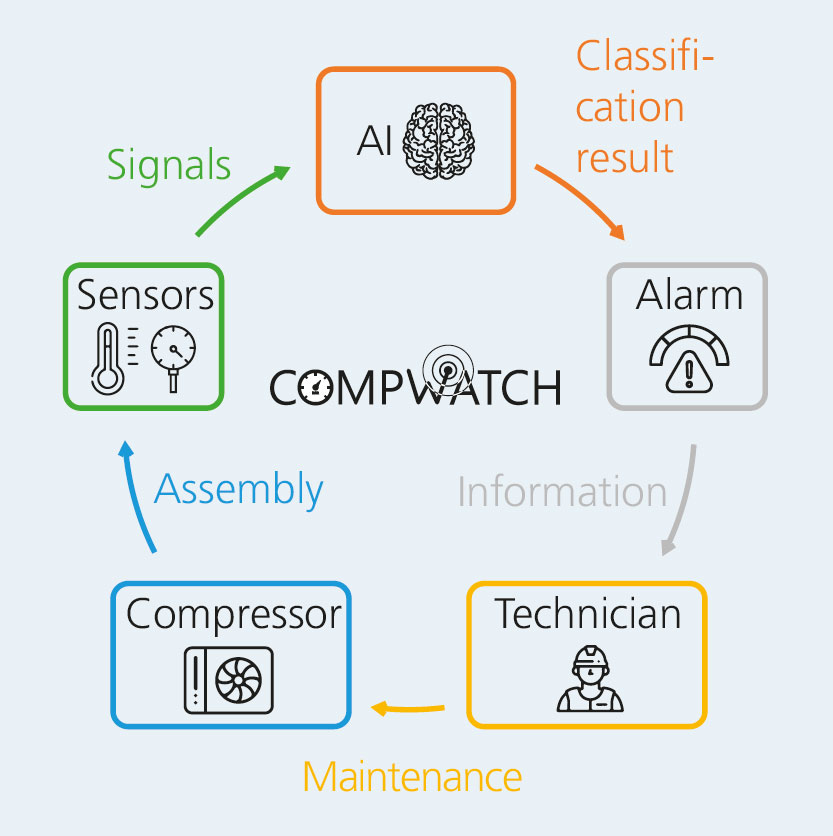

This is another area in which Fraunhofer IKTS can point to early successful projects with digital condition data: As part of the CompWatch project, funded by the German Federal Ministry of Education and Research (BMBF), researchers have developed a process for event-based maintenance intervals for compressor units. The self-learning system is embedded with the customer and “learns” what an intact compressor unit typically sounds like. Any anomalies in this operating sound indicate a potential damage. It is only in such an event that the system triggers a preventive maintenance assignment. It does not necessarily need to be familiar with all possible noises that can occur in a damage event, but it constantly learns and optimizes itself. As a result, based on typical operating sounds and using the ML algorithms developed by IKTS plus simple microphone equipment, operating costs and downtimes can be reduced significantly. Additionally, thanks to the collective intelligence gathered from all compressor units, maintenance companies will be able to prepare damage reports much faster and more efficiently in the future.