Metal-matrix composites with diatoms as fillers

Current research

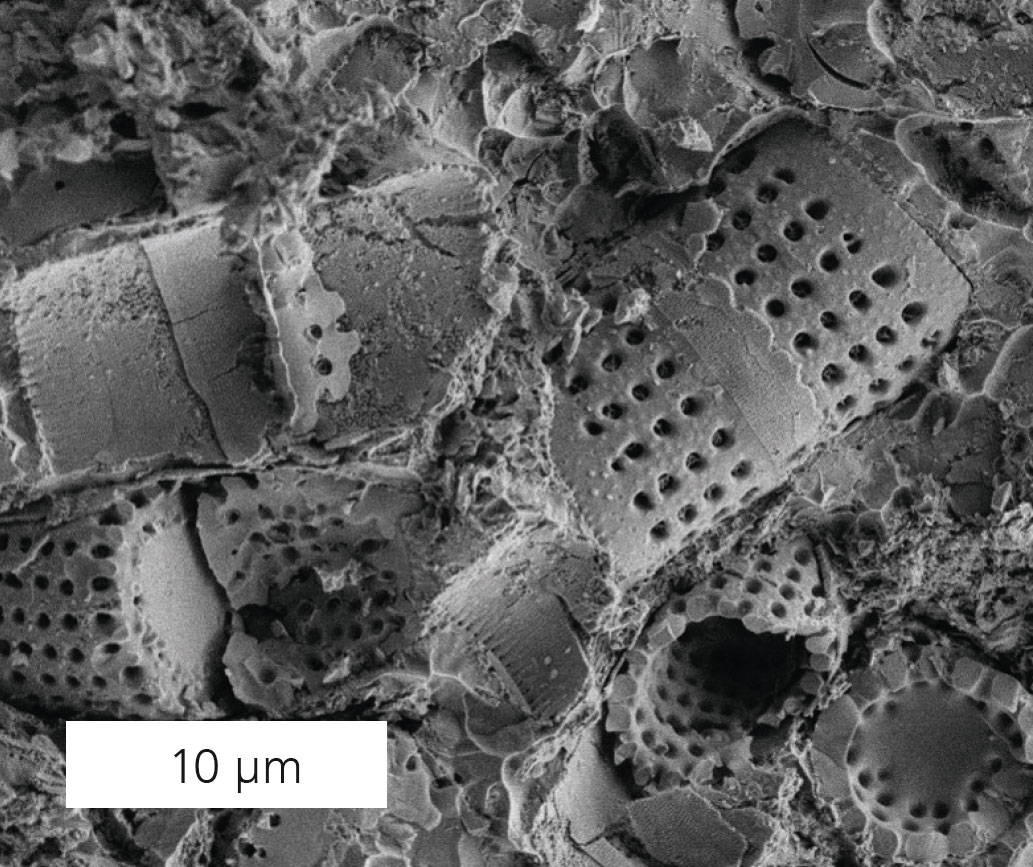

Diatomaceous earth is a biogenic siliceous sedimentary rock and consists mainly of fossil diatom shells (frustules). It can be extracted on a large scale and used as a natural component of composite materials.

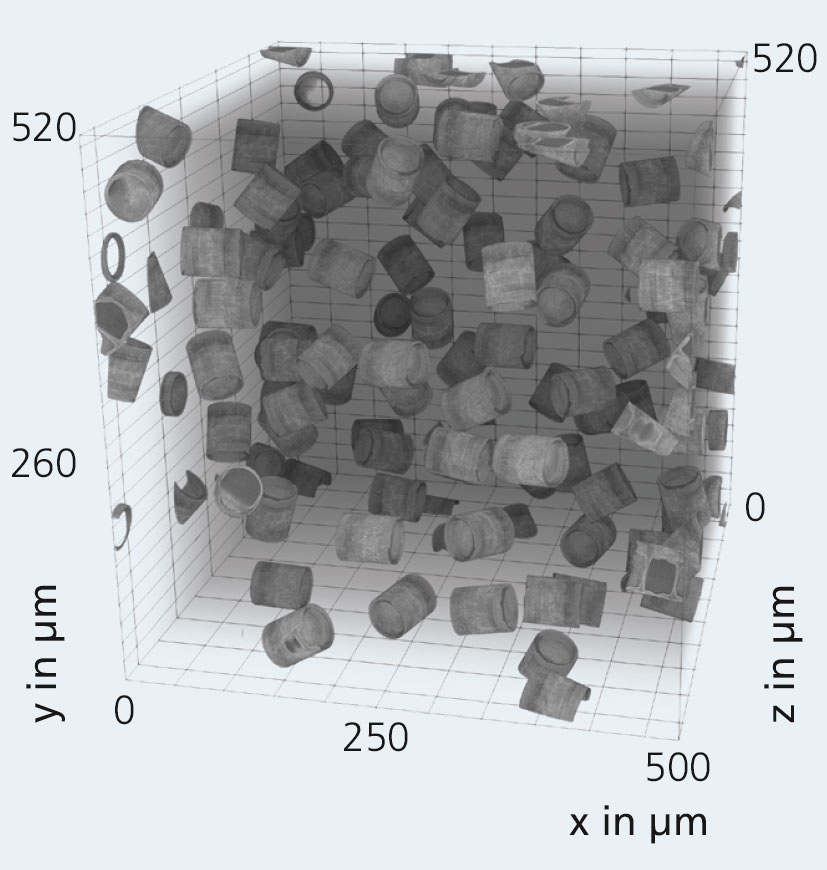

If the cylindrical frustules, which are up to 100 micrometres in size, can be embedded homogeneously in a metal matrix, it is possible to set specific mechanical properties for this composite material.

Microstructural analysis for ideally designed composite materials

The design of such composites requires detailed knowledge of the geometry and mechanical properties of the diatoms used. Various imaging methods (correlative microscopy), allow to obtain a comprehensive 3D analysis of the composite.

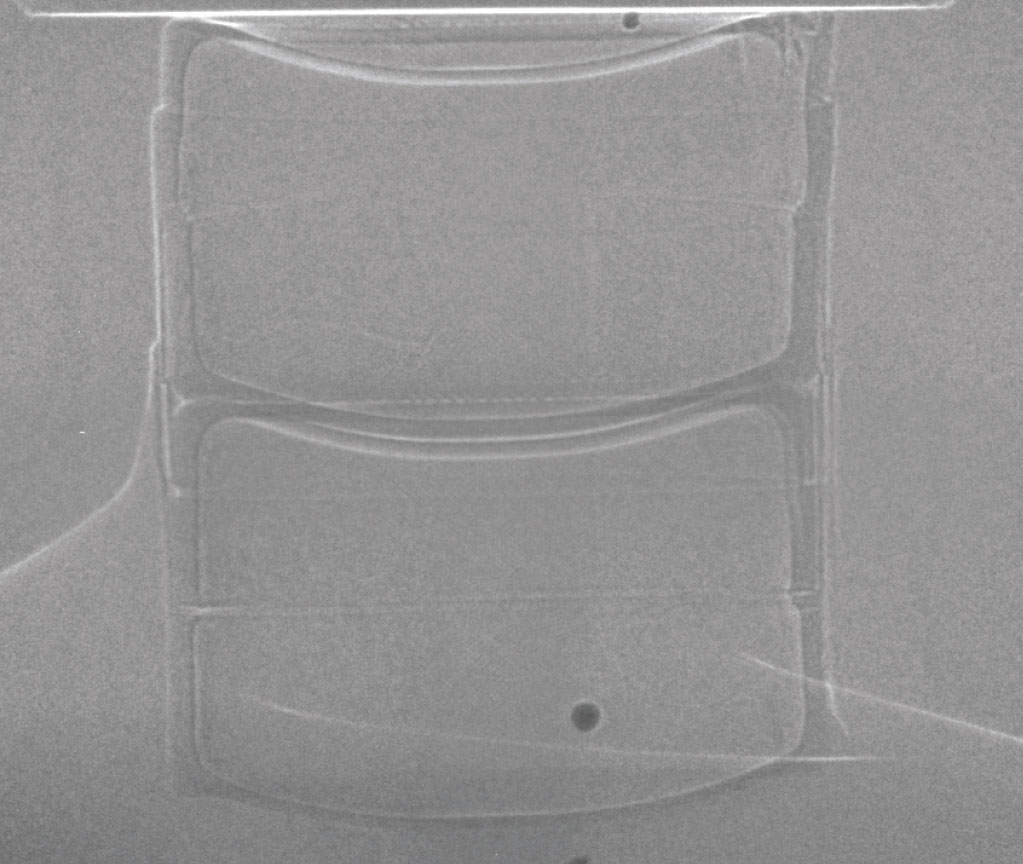

X-ray nano-tomography enables high-resolution, three-dimensional imaging of individual diatoms. The combination with in-situ loading tests allows to determine the forces that cause individual frustules. This data is the starting point for material simulations accompanying the project. On the one hand, the stress distribution in and around the pore formed by the frustule can be simulated. On the other hand, large FE models can be created directly from tomography data. The mechanical properties can be estimated through the software- supported generation of models with different filler contents. The results are used to produce and investigate test specimens in a targeted manner.

Pretreatment of frustules

To ensure that the diatoms in the metal-matrix composite form pores enclosed by frustules as uniformly as possible, the diatomaceous earth must be cleaned. For this purpose, wet sieving is advantageous over dry sieving, because it removes more fragments and foreign bodies.

The diatoms prepared in this way are then mixed with aluminum powder and processed into a solid composite material by Spark Plasma Sintering (SPS). In addition to powder metallurgical production, a melt metallurgical process is also being tested. In this process, the diatoms are mixed with the metal matrix in a liquid state.

The results were obtained in the German-Polish Cornet project MECODIA in cooperation with the University of Białystok.

Supported by