Sensor technology for exhaust gas purification

Sensor systems

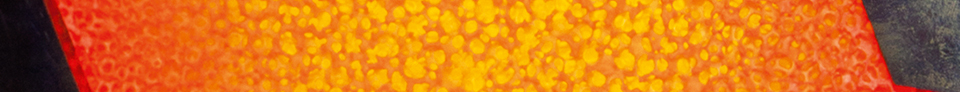

Thanks to the chemical resistance of ceramic materials, even in high temperatures, ceramic-based sensors are particularly suitable for use in tough environments, such as exhaust gas treatment and purification. Fraunhofer IKTS offers sophisticated sensor elements and sensor integration solutions from one single source. Based on the synthesis of functional ceramics or the processing of commercial materials, IKTS develops soot, mass flow, temperature and gas sensors for the most varied operating conditions. When it comes to producing sensor elements based on thick-film and multilayer technology, IKTS can boast many years’ worth of know-how in the field of ceramic pastes and inks, which are deposited onto ceramic, metallic and polymeric substrates using various printing methods. Using packaging and joining methods suitable for high temperatures, these components can then be reliably integrated in measuring systems.

To achieve reliable diagnostic functionality in automotive exhaust gas treatment applications, soot sensors must be robust and able to withstand the occurring aggressive atmospheres and the stress from high temperatures and strong vibrations. To ensure this, Fraunhofer IKTS has brought resistive soot sensors to maturity after optimizing their resistor and heating conductor structures, layer properties and packaging techniques.

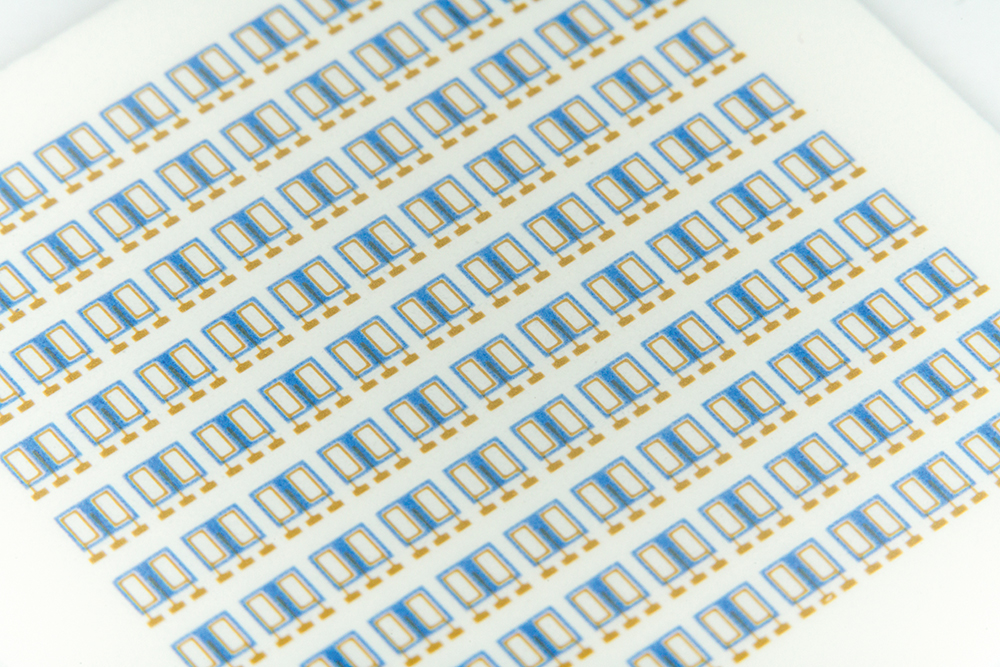

Fraunhofer IKTS is developing pulsation-capable mass flow sensors with the aim of reducing the particle, nitrogen oxide and carbon dioxide emissions in combustion processes. This makes it possible to improve exhaust gas control, in particular with regard to exhaust gas recirculation. The mass flow sensors are designed for determining the exhaust gas mass flow rates of diesel engine and biogas plants, as well as for use in portable emission monitoring systems (PEMS). The hybrid material approach consisting of a miniaturized, highly robust sensor element and a thermally uncoupled housing as well as an adapted high-temperature-capable packaging and joining technology enables use in rough ambient conditions.

Process temperature is an important factor in exhaust gas treatment and purification as it provides information on the system’s efficiency and condition. Measuring process temperature in as many spots as possible requires compact solutions that can be easily integrated. Fraunhofer IKTS offers HTCC-based temperature sensors for this purpose. They allow highly precise measurements in areas with up to 1000 °C. In conjunction with a specially developed housing, these elements can be used without any additional encapsulation, ensuring the fastest possible response times.

Fraunhofer IKTS also provides various gas sensors for the detection of O2, CO2, H2, CH4 or NH3. They can be adapted to the most varied operating conditions by selecting the right measuring approach, sensor design and operating parameters. Amperometric oxygen sensors based on Yttrium-stabilized zirconium oxide, for instance, can be used in temperatures of up to 700 °C and in a measuring range of 0 to 100 vol %. Multiple test stands are available at IKTS to characterize the interaction with gases, as well as other specific material properties.