A high reliability and availability of technical devices is crucial for local oxygen production in industrial applications. Frequently, a significant decrease of O2 permeation with time is predicted for MIEC materials (Mixed Ionic Electronic Conductor), especially for high flux material BSCF (Ba0.5Sr0.5Co0.8Fe0.2O3-δ). A slow phase decomposition in intermediate temperature range, a poisening or blocking by CO2 und SO2 from the atmosphere or a reaction of the membrane material with chromium oxide coming out of high temperature resistant steel are discussed as potential reasons.

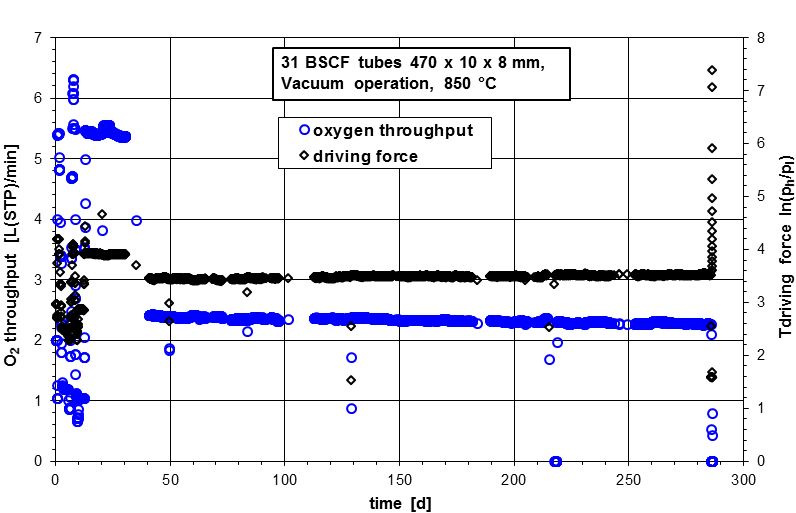

The diagram below shows the variation of O2 flow and driving force represented by the logarithmic ratio of O2 partial pressures for long-term operation of an O2 generator. The demonstration unit containing 31 BSCF tubes was used in vacuum operation mode. Previously to the testing period shown in the diagram, the device has finished a test for 2600 h resulting in a total operation time of 9500 h. During the 40 days at the beginning of the test period shown, vacuum pressure and air throughput were varied several times. Afterwards, the device was running at constant operation conditions but some power breakdowns results in unscheduled shutdowns and loss of data.

After the long-term test some tubes were investigated using SEM and EDX. Sulphur and chromium were detected on the membrane surface but formation of foreign phases too. But for all that, only a small decrease of appr. 6 % regarding O2 flow was observed for 250 days at constant operation conditions. Besides, the device tolerates arbitrary changes of operation conditions as well as power breakdowns and repeated restarts without any problems.

Services offered

- Basic engineering of MIEC plants

- Consulting for system integration

- Design and building up of pilot plants