POXOS® - Lowest operating costs and CO2 emissions for local oxygen production

Project

Interview with Dr.-Ing. Robert Hoffmann

POXOS® generators produce pure oxygen (O2) on site. The patented membrane separation process requires significantly less electricity than pressure swing adsorption. With a high annual utilization rate, the operating costs are significantly lower than for oxygen supply by delivery. Besides, CO2 emissions from oxygen supply can be lowered by more than 50 percent.

Use for water treatment

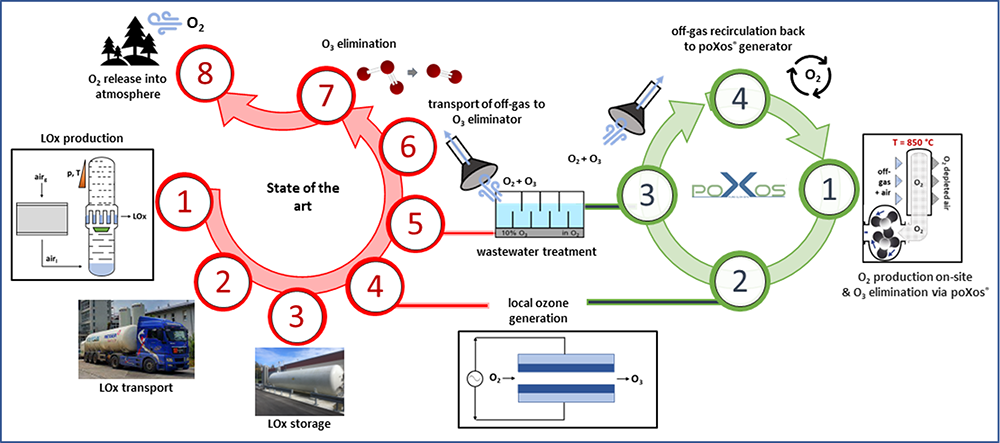

Particularly high savings are achieved in wastewater treatment with ozone. The delivery, storage and evaporation of LOx (Liquid Oxygen - cryogenic liquid oxygen) to feed the ozone generators is no longer necessary. The oxygen rich off-gas leaving the wastewater is fed back to the POXOS® generator. The generated oxygen is fully utilized while a closed cycle of process is achieved. In addition, the usually required residual ozone eliminator is unnecessary. If the POXOS® - generator is operated with sewage gas, a CO2-neutral production of the oxygen is possible.

With an annual demand of 500,000 m³ O2 and a supply price of 0.25 €/m3, an annual saving of 100,000 € can be achieved.

Sustainable – fully recyclable

POXOS® generators are designed to be recycled at the end of their service life. The ceramic membrane material contained is fully recycled into the manufacturing process of new membranes to minimize the consumption of resources.

POXOS® efficiently closes the oxygen supply circle in wastewater treatment

Further areas of application

Every O2 application benefits from the low operating costs and CO2 emissions of on-site O2 generation with POXOS® generators.

- Medical facilities can be supplied with high-purity and sterile oxygen. The approval process has already been initiated.

- In fish farming, higher stocking rates and accelerated growth become possible.

- In combustion processes using oxygen, efficiency can be significantly increased. Energy-intensive high-temperature processes, e.g. in metallurgy, glass or cement production, benefit particularly from the resulting fuel savings of up to 50 percent. In addition, combustion with pure oxygen (oxyfuel) is enhanced with formation of concentrated CO2. Usually, its separation needs typically additional energy.

Current issues of development

Currently, the combustion of lean gas for heating the POXOS® generators is investigated. The devices have to be adjusted according to the recycling of the oxygen rich off-gas. In addition, an adjustable increase of oxygen pressure must be realized.

The first customer tests of prototypes under real operation conditions were carried out in 2023. POXOS® generators are expected to be ready for the market in 2024.

In parallel, the potential of fuel saving and CO2 separation from oxyfuel processes will be investigated.

Proposed startup

POXOS®, a proposed Fraunhofer IKTS startup is intended to comercialize a patented membrane separation process for oxygen production.

The project poXGen (FKZ: 03EFSTH033) is part of the EXIST program and funded by the Federal Ministry of Economic Affairs and Climate Action and the European Social Fund.

Have we drawn your interest?

We are convinced that POXOS® can bring savings for your applications! Get in contact with us!

We are happy to counsel you!