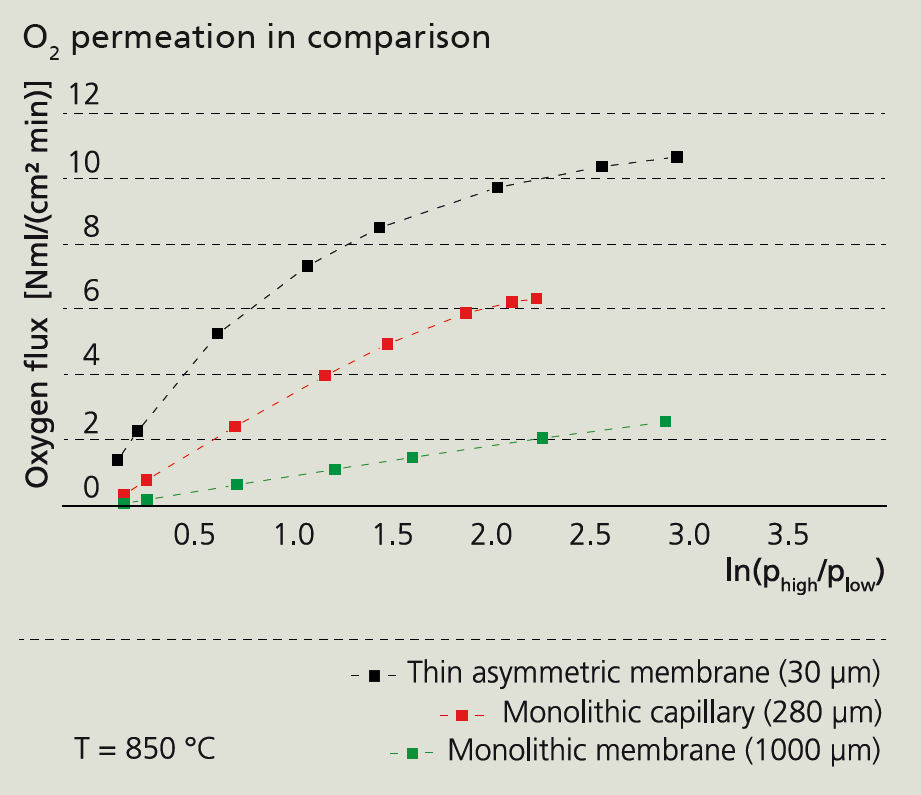

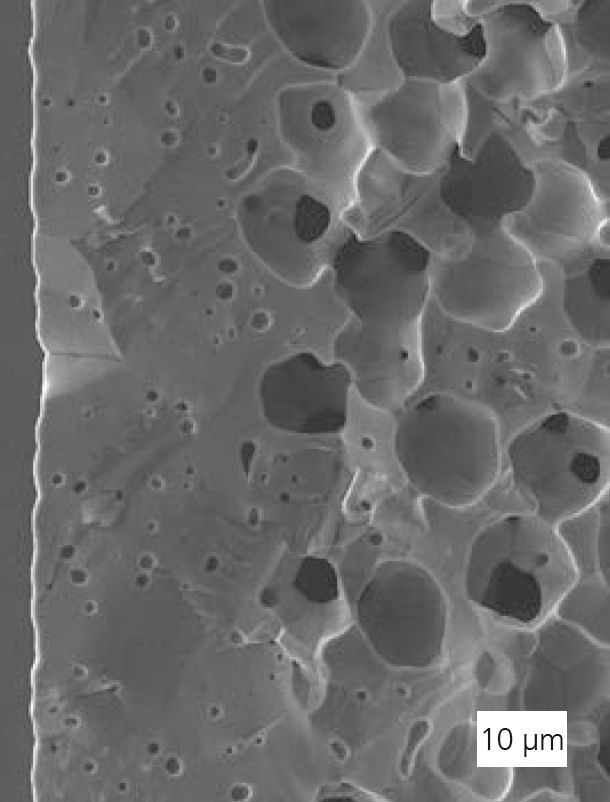

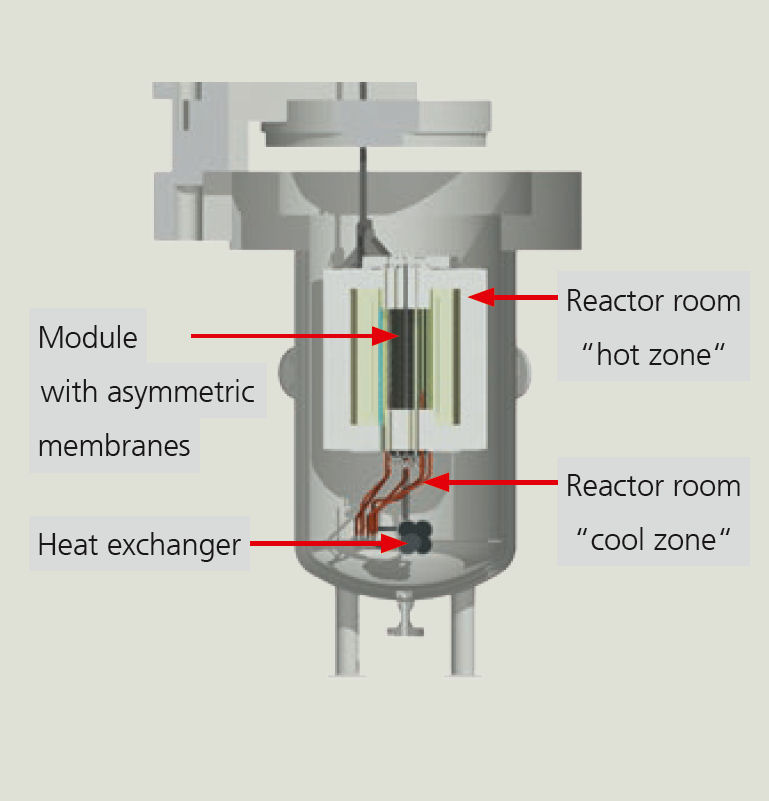

Oxygen is one of the most frequently required industrial gases, with around 100 million metric tons consumed worldwide every year. Conventional production processes are very energy-intensive and the price of O2 increases sharply for lower purchase quantities. The O2 generators based on mixed conductive ceramic membranes (mixed ionic electronic conductor – MIEC) developed at Fraunhofer IKTS are an alternative. Gas separation is highly selective at approx. 850 °C via the coupled transport of oxide ions and electronic charge carriers. Up to now, membrane tubes or capillaries – so-called monolithic membranes – have been used in O2 generators by IKTS. The relatively large wall thickness of these membranes (e.g. 280 μm for the capillaries) meant that large quantities (approx. 300 to 400 capillaries for 1 Nm3 of O2/h) were required. By contrast, lower membrane thicknesses lead to a considerable increase in O2 permeation. In order to ensure the mechanical stability of membranes with thicknesses of 20 to 30 μm, these are applied onto an open-pored carrier ceramic (asymmetrical membranes). Manufacturing of such “asymmetric MIEC membranes“ of BSCF (Ba0,5Sr0,5Co0,8Fe0,2O3-x) was simplified and drastically optimized within the EU project “HETMOC“ (Grant Agreement No. 268165). For the first time, membranes with a length of 750 mm were manufactured in a quantity sufficent for testing in a pilot plant. All in all, 3 modules, each of them equipped with 25 asymmetric membrane tubes, were tested successfully for several months at 5 bar air-side pressure by the project partner DTU of Denmark. The following chart compares the area-normalized O2 permeation of an asymmetric membrane, a capillary, and a monolithic membrane tube. Since the asymmetric membrane’s flow rate is multiple times that of a monolithic membrane, the required number of membranes produced decreases considerably. The purity of the O2 produced by asymmetric membranes is reduced to approx. 96–98 vol % O2 because of few pinholes inside the thin separation layer, which are hard to eliminate. Nevertheless, it was possibe to realize smaller and cheaper O2 generators by using the new asymmetric MIEC membranes. Accordingly, such membranes are presently used in the project “IBIS“ (BMBF: 01LY1616A), which deals with the O2 enrichment of combustion air in an industrial furnace. Fuel gas savings are expected.