Industry-oriented continuous manufacturing of ceramic foam

Current research

Ceramic foams are usually manufactured on continuously working rolling mills using Schwartzwalder replica technique. Testing changes in the recipes of ceramic suspensions in operation are very challenging due to the associated efforts (production stop, cleaning, change-over, rejects). At the same time, slurries and system parameters optimized in the laboratory can only be partly transferred to the real conditions of industrial rolling mills. For this reason, Fraunhofer IKTS has developed and implemented a new continuously working coating line for foams in ist technological center. It is designed for research purposes for the transfer from lab scale to mass production and has a high degree of freedom for adjustments. It consists of three freely combinable units:

- Impregnation unit: slurry impregnation of the foam via exchangeable rolls with structured or specially prepared surfaces

- Homogenization unit: squeezing out of surplus material and setting to open or closed side walls

- Spray unit: reinforcement of the external foam surface by spraying slurries onto coated green bodies or applying functional coatings after sintering

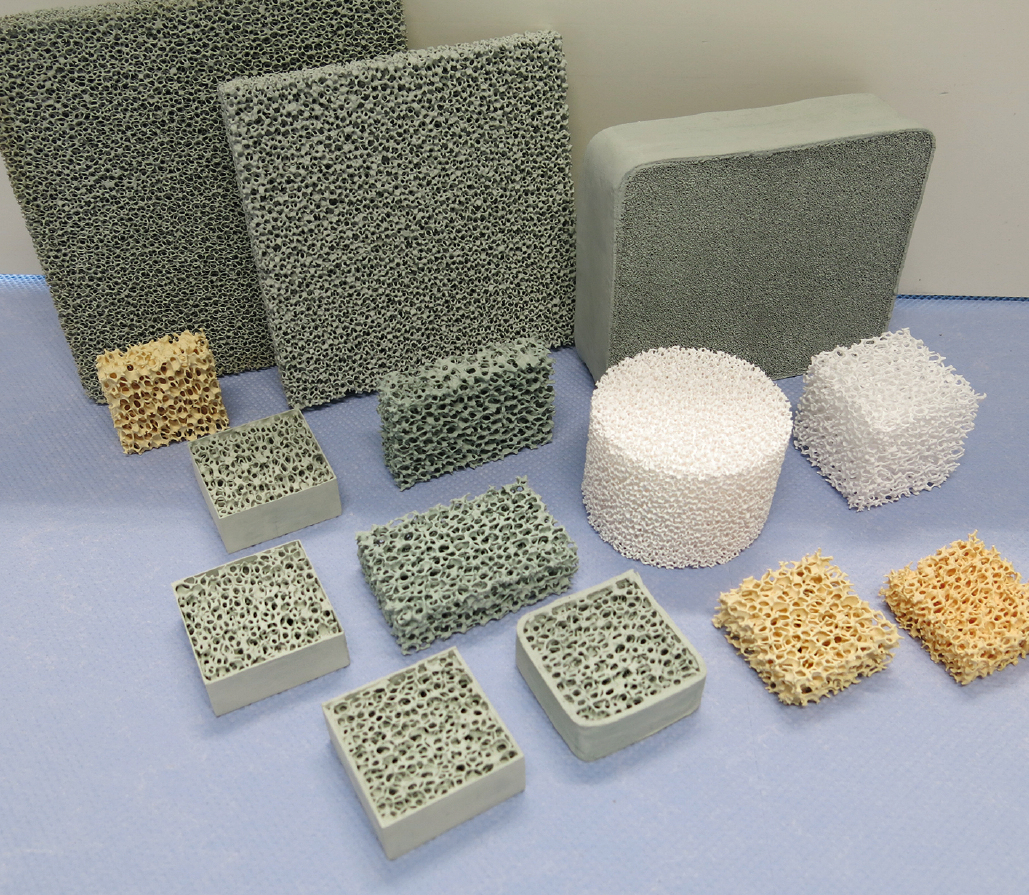

The coating plant in pilot scale is designed for lateral foam sizes of 200 x 200 mm2 and variable height. The plant’s high effectiveness is particularly noteworthy: Depending on the geometry, up to 60 specimens can be manufactured per hour. Thanks to the excellent infrastructure of intensive mixers to support the new equipment, the significantly larger slurry amounts needed can be produced and provided with a very high standard of mixing and storage quality. Subsequently, slurry properties will be investigated intensively with scientific and application-oriented specifications in order to adapt production conditions and provide partners with characteristic parameters for production and quality assurance. This is based on the long years of experience of IKTS in the development and manufacturing of highly filled slurries for foam manufacturing, including new oxide and non-oxide ceramic materials. The production of ferrous and non-ferrous metal slurries, which can be manufactured by replica technique as well, is another capability provided.

Services offered

- Development, optimization, testing of slurries for continuous foam coating

- Adaptation of coating technique to specific filter designs, i.e. lateral frames

- Consulting and support for the setup of foam coating plants