In the construction industry, many materials such as screed are installed and processed in a moist state. After the building materials have been processed, excess water that is not required for the setting process must be released into the ambient air via the component boundaries within a time period that is as defined as possible. To reduce the consumption of energy and resources in production as well as in the application in the building structure, it is necessary to monitor these drying times as precisely and simply as possible. This shortens waiting periods in construction operations and allows an objective assessment of the water content in order to prevent damage to the building, for example, by covering the screed too early.

In particular, the drying behavior in the critical range of 0 to 3 % residual moisture is often only a time estimate without fully considering external factors such as screed composition, ambient temperature and humidity as well as geometrical conditions. The standardized test methods do not work non-destructively. To effectively shorten waiting times during construction and avoid structural damages, a disposable sensor for moisture measurement is required that can be cast into the screed and remain there, as well as providing reliable drying data.

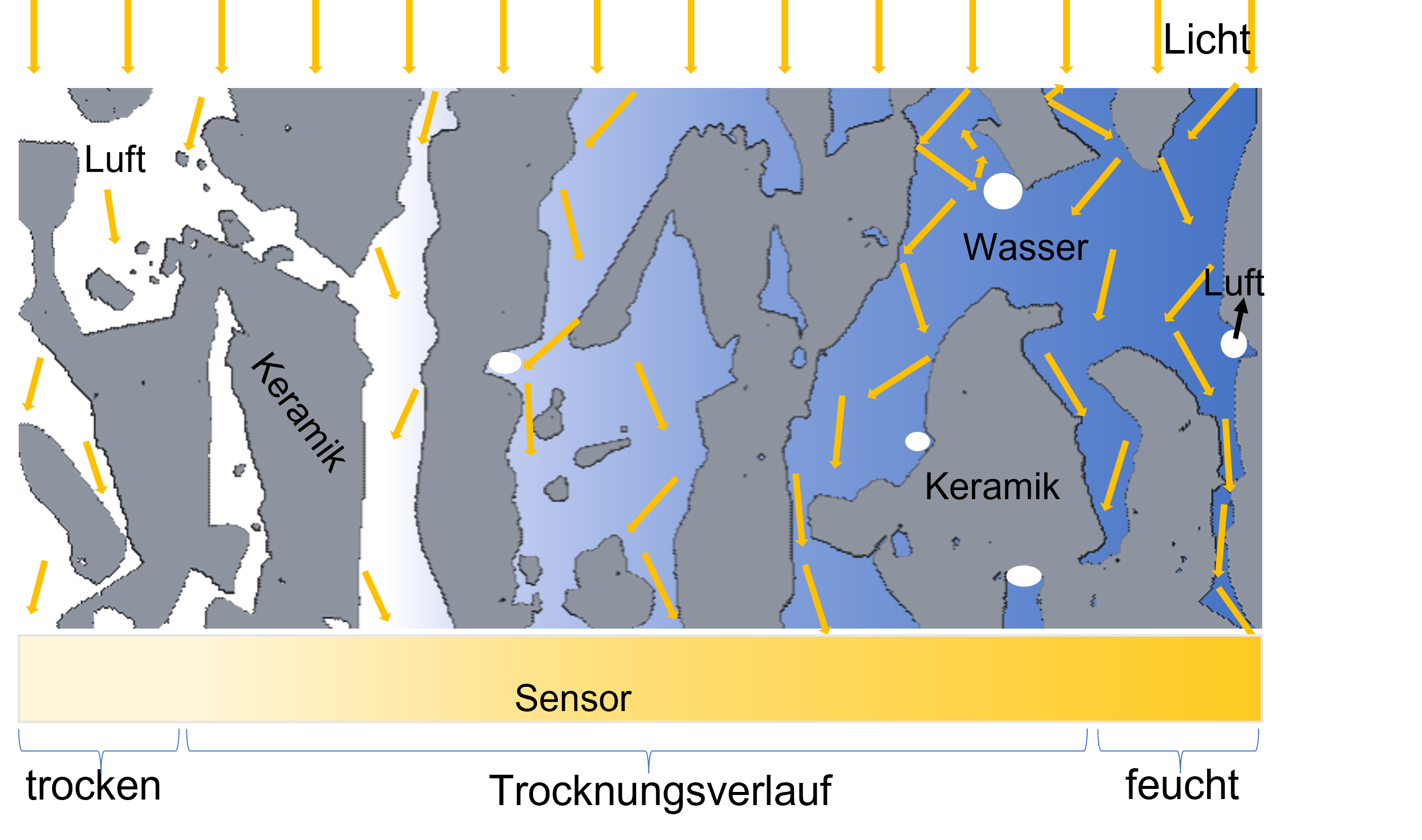

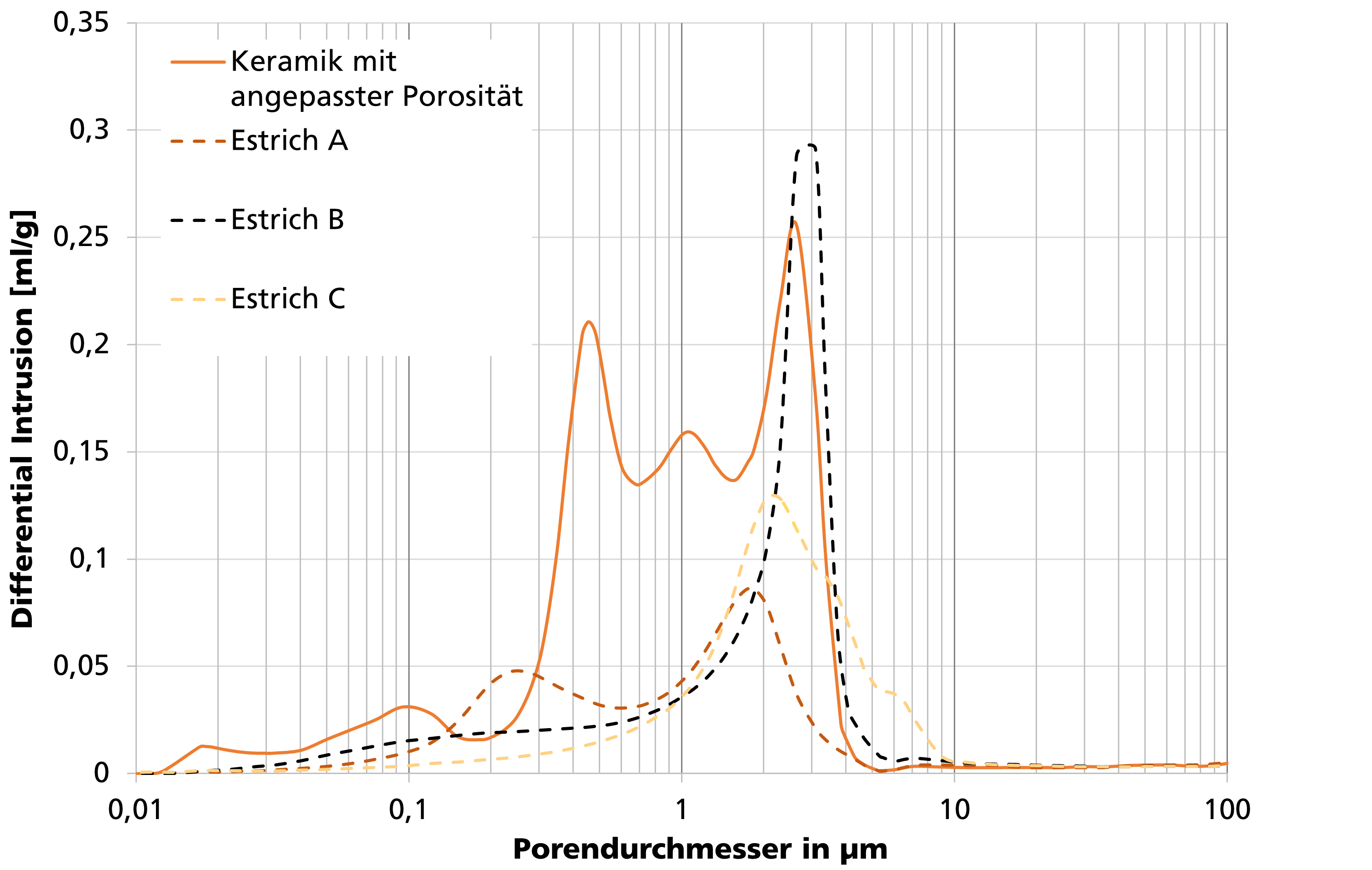

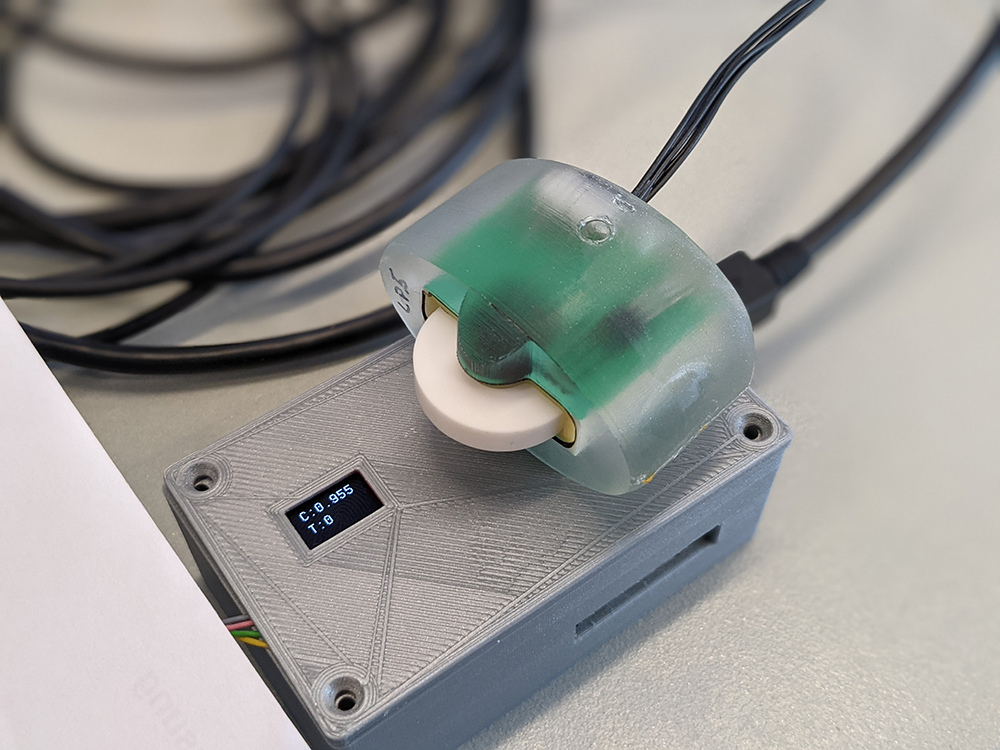

Fraunhofer IKTS is developing moisture sensors based on porous ceramics that exploit the improved light conduction of water-filled pores. The light conduction decreases during drying and is insensitive to salt contents in the water as well as varying temperature. Customized porous sensor ceramics matched to the screeds in pore sizes and porosity can be used to optically measure the drying process. Within the scope of the current research, suitable ceramics as well as a suitable sensor structure are being developed.

Project title: KeraSens

Funding: AiF/Forschungsvereinigung der Gipsindustrie e.V.

Funding code: IGF 20936 BR/2

Project partner: Materialforschungs- und -prüfanstalt an der Bauhaus-Universität Weimar (MFPA)